Figure 4.2 :

Filters

IMPORTANT:

Orkel recommends that the operator regularly performs visual controls of the compactor as well as act-

ive listening for abnormal noises. Perform adjustments as soon as there is a need. A problem that is not

immediately rectified may cause further problems, and in worst case lead to mechanical breakdown.

No Checkpoints during and after break-in period

1

Grease collar. Check that all bearings have grease collar.

2

Perform visual control of the compactor – before, during and after use.

3

Grease pump. Check pressure relief valve, no visible grease shall be present.

4

Elevator chain. Check tension after 1-3 hours of operation

5

Check and adjust elevator and sensor.

6

Replace filters after the first 50 hours of operation.

7

Change hydraulic oil after 50 hours of operation.

8

Listen for abnormal noises.

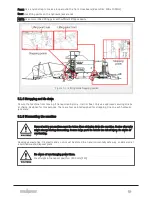

4.5 AUTOMATIC OPERATION

IMPORTANT: If the tank valves are closed when the PTO is started, there is a high risk of damaging the

hydraulic system. Before starting, please make sure that all tank valves are open. See

4 OPERATION

40

Summary of Contents for MP2000-X

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 98: ...8 6 4 Gearbox and gears for hydraulic motors Gear oil Renolin unisyn CLP 220N 8 LUBRICATION 98...

Page 99: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 99...

Page 100: ...8 7 2 Feed hopper F10 8 LUBRICATION 100...

Page 101: ...8 7 3 Telescopic drawbar 8 LUBRICATION 101...

Page 105: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 105...

Page 106: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 106...

Page 107: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 107...

Page 108: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 108...

Page 120: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 120...

Page 124: ...11 1 1 Complete diagram 11 HYDRAULICS 124...

Page 125: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 125...

Page 128: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for MP2000 X 11 HYDRAULICS 128...

Page 132: ...12 6 3 Dimensional sketch F10 operating mode 12 SPECIFICATIONS 132...

Page 133: ...12 6 4 Dimensional sketch F10 transport mode 12 SPECIFICATIONS 133...

Page 137: ...M Maintenance 13 65 67 INDEX 137...