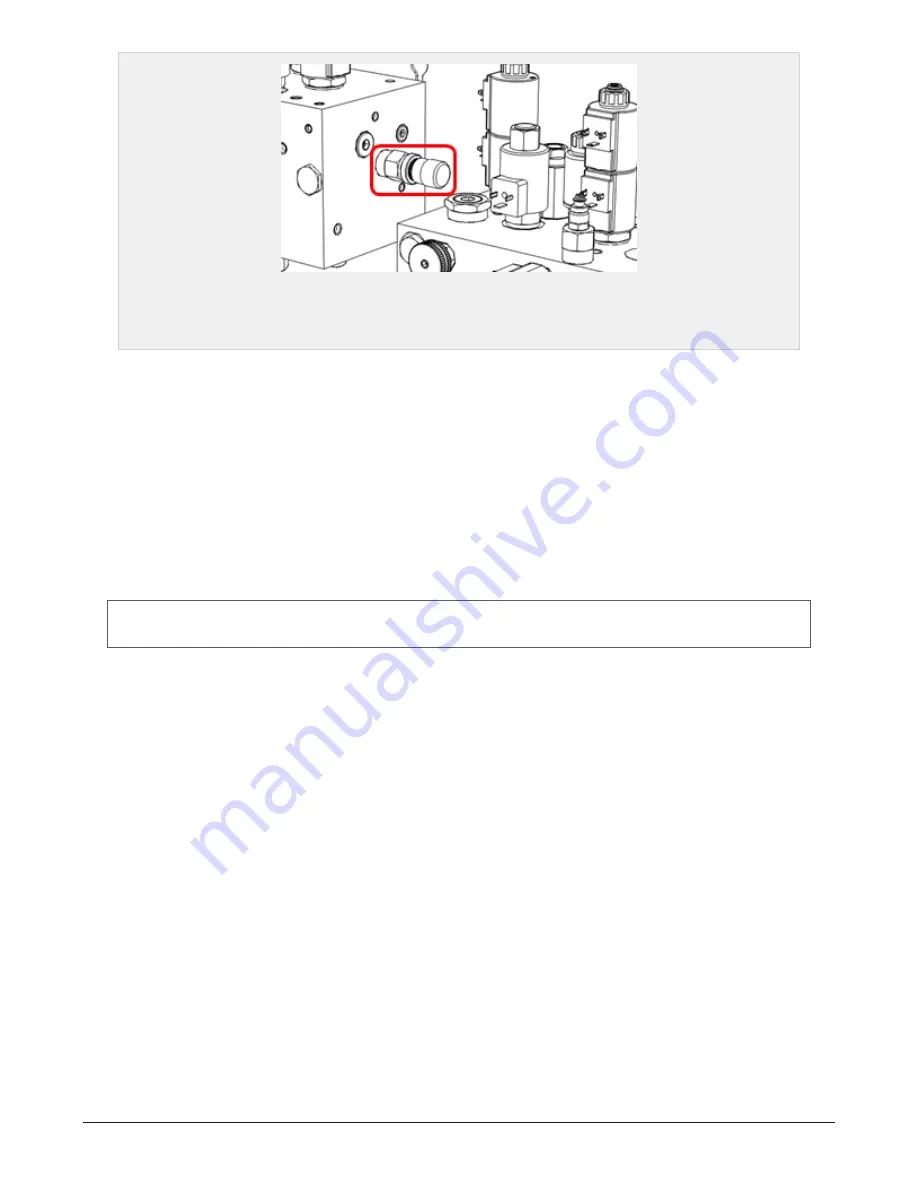

Figure 3.2 :

The red box indicates the M1 valve

3.4 ELEVATOR AND SUB CONVEYOR

3.4.1 Settings

The speed of the elevator belt and the sub conveyor may be changed from the display unit, on the machine

settings page.

3.5 CHAMBER

The bale chamber can handle high loads, but the set chamber pressure and the resulting bale density must

be considered and possibly limited according to type of material. When baling certain material, too high

chamber pressures may reduce the bale chamber life time. See

section 6.1.7 "Machine settings"

and

tion 6.1.17 "Settings and explanations"

for how to set the chamber pressure.

NOTE: All references to valves found in this sub chapter can be found in the hydraulic schematic and valve over-

view in

3.5.1 Opening speed settings

Closing speed: Adjusting the bale chamber closing speed is done by turning the K1 valve. Clockwise

decreases the speed. Counterclockwise increases the speed.

Default setting: Close the valve and then open 1/2 turn.

3.5.2 Chamber pressure settings

The chamber pressure settings is set on the display unit. When the baling starts, the elevator will run at its

higher set speed. When the chamber pressure surpasses the elevator slow threshold, the speed is reduced

in order to allow a higher bale density. The bale is done when set maximum chamber pressure is reached.

The plastic tying unit will then start.

Parameters that may be set on the display unit are:

Chamber max pressure: 100 - 280 bar

Elevator slow threshold: 30 - 100% of set pressure

Example:

Material: Wood chips

Set chamber pressure: 180 bar

Chamber slow threshold: 75 %

3 SETTINGS AND HYDRAULIC ADJUSTMENTS

25

Summary of Contents for MP2000-X

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 98: ...8 6 4 Gearbox and gears for hydraulic motors Gear oil Renolin unisyn CLP 220N 8 LUBRICATION 98...

Page 99: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 99...

Page 100: ...8 7 2 Feed hopper F10 8 LUBRICATION 100...

Page 101: ...8 7 3 Telescopic drawbar 8 LUBRICATION 101...

Page 105: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 105...

Page 106: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 106...

Page 107: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 107...

Page 108: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 108...

Page 120: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 120...

Page 124: ...11 1 1 Complete diagram 11 HYDRAULICS 124...

Page 125: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 125...

Page 128: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for MP2000 X 11 HYDRAULICS 128...

Page 132: ...12 6 3 Dimensional sketch F10 operating mode 12 SPECIFICATIONS 132...

Page 133: ...12 6 4 Dimensional sketch F10 transport mode 12 SPECIFICATIONS 133...

Page 137: ...M Maintenance 13 65 67 INDEX 137...