high density bale. The brake force should be set when net/film is pulled during the automatic net/film

sequence. The brake force is shown on the brake pressure gauge. The valve for the brake pressure is adjus-

ted consecutively until the appropriate brake force is reached. Start the adjustment with a low brake

force, and increase it. If the brake force is too high, this might damage or even rupture the net or film.

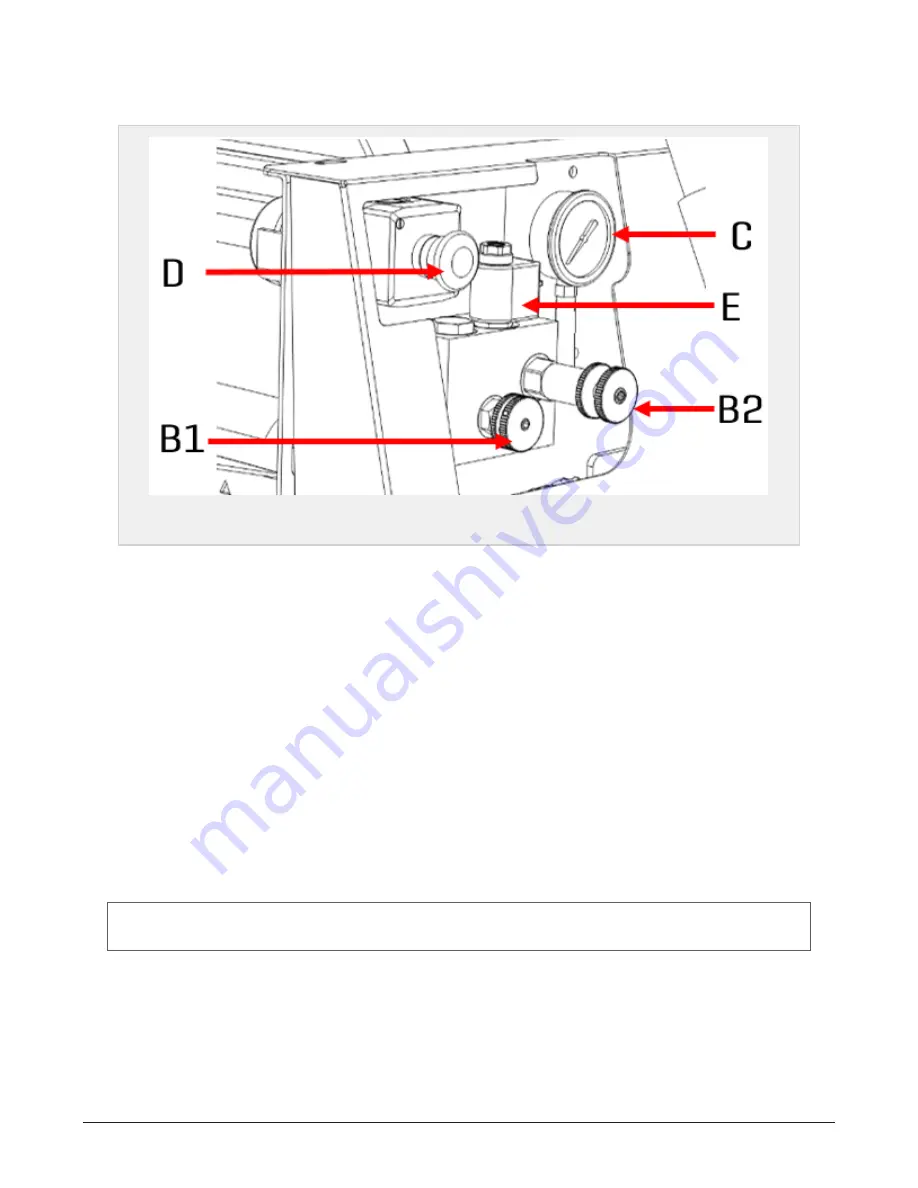

Figure 3.4 :

Brake and feed speed controls

B1 Valve for feed speed

B2 Valve for brake force

C Gauge

D Emergency stop switch

E Electrical valve for brake release/engagement

3.6.3 Settings

Feed speed: Adjusting the feed speed is done by turning the B1 valve. Clockwise decreases the speed. Coun-

terclockwise increases the speed.

Default setting: Close the valve and then open 3/4 turn.

Brake force: In order to maintain tension, the film roller is slowed down when being laid on the bale. Adjust-

ing this brake force is done by turning the B2 valve. Clockwise increases the brake force. Counterclockwise

decreases the brake force.

Default setting: Increase the pressure and notice the pressure on the manometer when the film breaks.

Then slightly decrease the pressure.

NOTE: When starting the machine cold, the brake pressure might be higher. Therefore, set the pressure by

cold oil or readjust when the oil temperature has increased.

Brake release valve: The brake is controlled electrically from the display unit or from the remote control

on the platform. See

section 6.1.6 "Manual controls"

and

section 3.6.4 "Remote control"

3 SETTINGS AND HYDRAULIC ADJUSTMENTS

27

Summary of Contents for MP2000-X

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 98: ...8 6 4 Gearbox and gears for hydraulic motors Gear oil Renolin unisyn CLP 220N 8 LUBRICATION 98...

Page 99: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 99...

Page 100: ...8 7 2 Feed hopper F10 8 LUBRICATION 100...

Page 101: ...8 7 3 Telescopic drawbar 8 LUBRICATION 101...

Page 105: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 105...

Page 106: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 106...

Page 107: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 107...

Page 108: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 108...

Page 120: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 120...

Page 124: ...11 1 1 Complete diagram 11 HYDRAULICS 124...

Page 125: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 125...

Page 128: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for MP2000 X 11 HYDRAULICS 128...

Page 132: ...12 6 3 Dimensional sketch F10 operating mode 12 SPECIFICATIONS 132...

Page 133: ...12 6 4 Dimensional sketch F10 transport mode 12 SPECIFICATIONS 133...

Page 137: ...M Maintenance 13 65 67 INDEX 137...