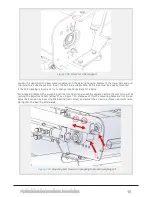

Figure 7.12 :

Front chamber belt is

tracking towards A/B

Figure 7.13 :

Front chamber distance C

Loosen the attaching bolts, to allow a movement of the bracket. Loosen the counter nut and adjust the dis-

tance C by turning on the adjustment nut.

Tighten the counter nut and the attaching bolts of the bracket when the belt has a correct tracking.

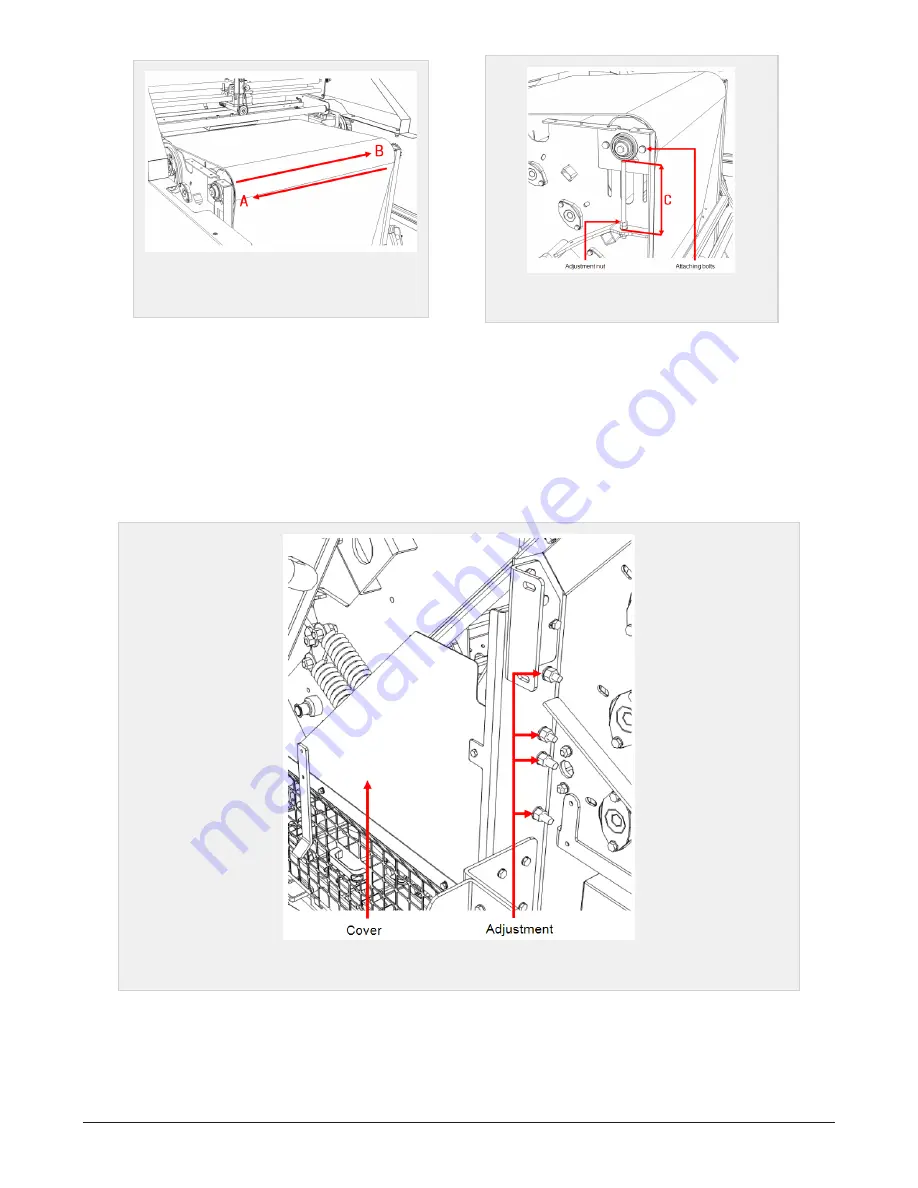

7.8.3 Adjusting the rear chamber belt

The adjustments of the rear chamber belt is done preferably from the right side of the machine. Dismount

the cover and safety net (

) to get access to the adjusting bracket and bolts seen in

.

Figure 7.14 :

Rear chamber adjustments

Rear tension roller

Adjusting the belt tracking is done by changing the distance C on the rollers bearing point D (

)

7 MAINTENANCE AND MECHANICAL ADJUSTMENTS

76

Summary of Contents for MP2000-X

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 98: ...8 6 4 Gearbox and gears for hydraulic motors Gear oil Renolin unisyn CLP 220N 8 LUBRICATION 98...

Page 99: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 99...

Page 100: ...8 7 2 Feed hopper F10 8 LUBRICATION 100...

Page 101: ...8 7 3 Telescopic drawbar 8 LUBRICATION 101...

Page 105: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 105...

Page 106: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 106...

Page 107: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 107...

Page 108: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 108...

Page 120: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 120...

Page 124: ...11 1 1 Complete diagram 11 HYDRAULICS 124...

Page 125: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 125...

Page 128: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for MP2000 X 11 HYDRAULICS 128...

Page 132: ...12 6 3 Dimensional sketch F10 operating mode 12 SPECIFICATIONS 132...

Page 133: ...12 6 4 Dimensional sketch F10 transport mode 12 SPECIFICATIONS 133...

Page 137: ...M Maintenance 13 65 67 INDEX 137...