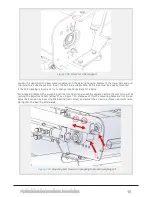

Figure 7.31 :

Check for play in the bushings. Red markings indicate areas on the

bushings.

There are two typical conditions of a worn out bushing, depending on where the bushing is located on the

machine. Read the description and see

.

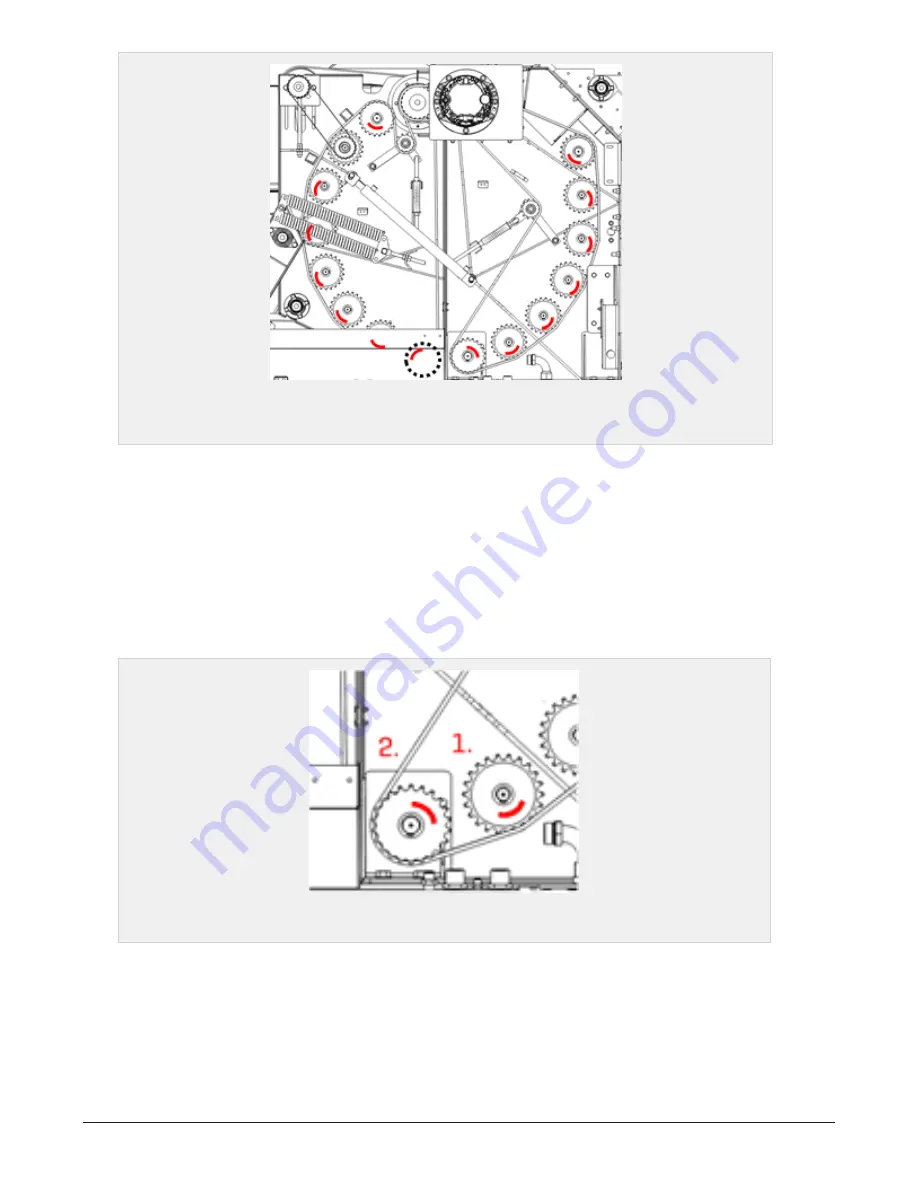

1. Bale pressure

This is the most typical condition. These bushings are worn the most when the chamber is «full», and the

bale pressure forces the rollers outwards. Thus the most wear on the bushings will be on the outer side.

2. Drive chain

This condition occurs on the bushings that are affected by the drive chain direction. A turning point is

shown in

. The wear is also influenced by the chamber pressure. But not as excessive as for con-

dition 1. Thus the most wear in these conditions are located on the opposite side of the chain contact side.

Figure 7.32 :

Bushings

Inspection

Use a crowbar and inspect each bushing from multiple angles. The worn out areas might be located at dif-

ferent possitions according to how the machine has been used, and which material has been baled.

7.12.2 Permissible wear

Small type, 40 mm

7 MAINTENANCE AND MECHANICAL ADJUSTMENTS

85

Summary of Contents for MP2000-X

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 98: ...8 6 4 Gearbox and gears for hydraulic motors Gear oil Renolin unisyn CLP 220N 8 LUBRICATION 98...

Page 99: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 99...

Page 100: ...8 7 2 Feed hopper F10 8 LUBRICATION 100...

Page 101: ...8 7 3 Telescopic drawbar 8 LUBRICATION 101...

Page 105: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 105...

Page 106: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 106...

Page 107: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 107...

Page 108: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 108...

Page 120: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 120...

Page 124: ...11 1 1 Complete diagram 11 HYDRAULICS 124...

Page 125: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 125...

Page 128: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for MP2000 X 11 HYDRAULICS 128...

Page 132: ...12 6 3 Dimensional sketch F10 operating mode 12 SPECIFICATIONS 132...

Page 133: ...12 6 4 Dimensional sketch F10 transport mode 12 SPECIFICATIONS 133...

Page 137: ...M Maintenance 13 65 67 INDEX 137...