IG-123-EN version 11; 23/07/2021

47

General instructions

cpg

.0: GIS medium-voltage switchgear,

gas insulated, up to 40.5 kV,

in accordance with IEC Standard

Operations sequence

For standard cubicles:

•

cpg

.0-v up to 24 kV/1600 A/25 kA

•

cpg

.0-v 40.5 kV up to 1250 A/31.5 kA

•

cgp

.0-v up to 36 kV/up to 1600 A/31.5 kA

•

cpg

.0-v up to 36 kV/up to 2500 A/31.5 kA

•

cpg

.0-vl up to 36 kV/up to 1250 A/31.5 kA

The lever for manual charging of the aforementioned

CIRCUIT-BREAKERS' closing springs is identifi ed by its

black knob.

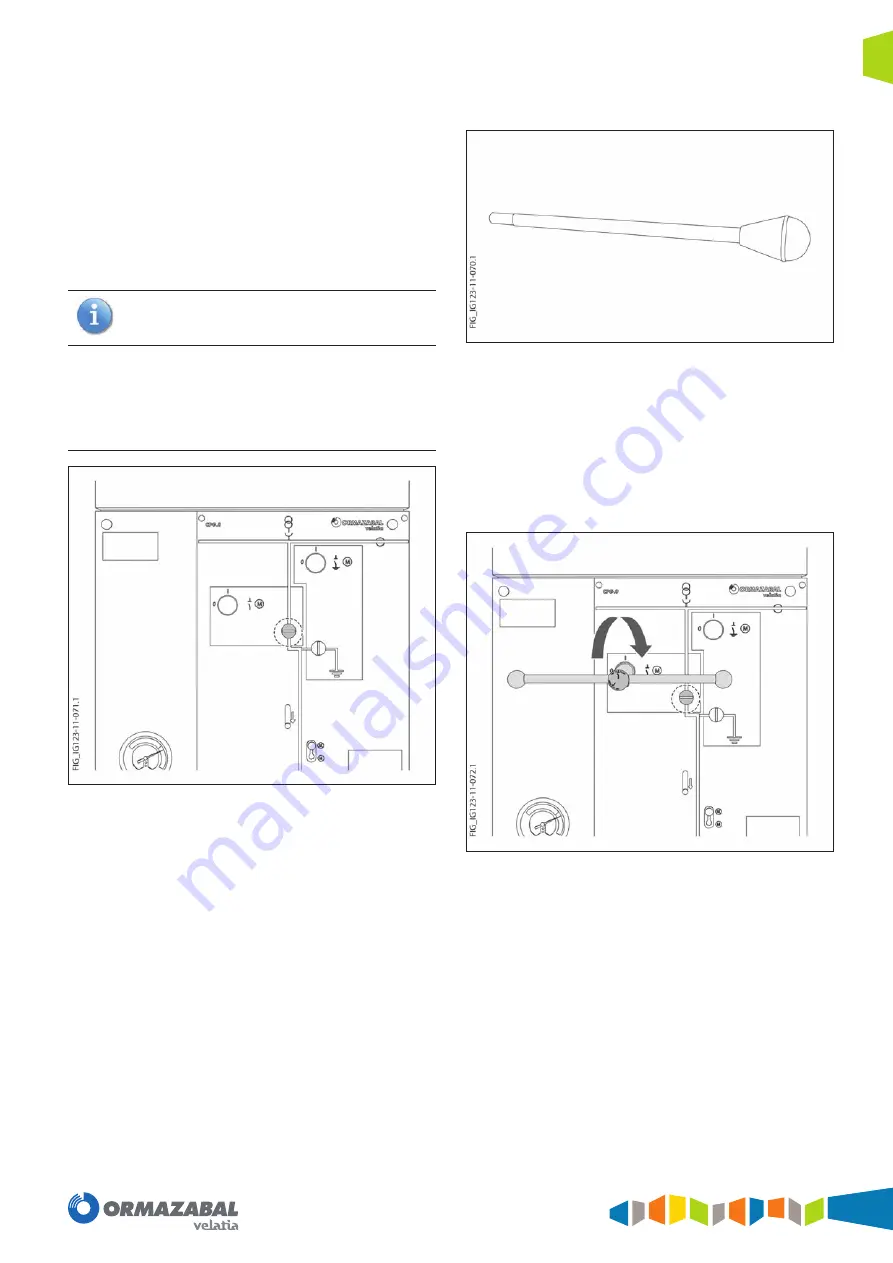

Figure 7.23.

Details of the circuit-breaker's manual spring charging lever

a. Manual circuit-breaker operation

Connection

Figure 7.24.

Starting position of the

cpg

.0-v

disconnector

Insert the lever in the feeder disconnector's actuating shaft.

Then turn 90º CLOCKWISE. Check that the disconnector

status indicator shows closed.

Figure 7.25.

Feeder disconnector closing sequence

Summary of Contents for velatia cpg.0

Page 79: ......