IG-123-EN version 11; 23/07/2021

75

General instructions

cpg

.0: GIS medium-voltage switchgear,

gas insulated, up to 40.5 kV,

in accordance with IEC Standard

Maintenance

9. Maintenance

For safety reasons, maintenance operations performed

directly on the driving mechanism must be performed

WITHOUT any actuating levers inserted.

The live parts of the main circuit in

cpg

.0 cubicles do not

require inspection or maintenance, thanks to their gas-fi lled

insulation, meaning there is no infl uence from external

environmental factors. Class E2 electrical endurance tests

mean that the breaking components are maintenance free.

For all other elements, follow the preventive maintenance

instructions indicated by

Ormazabal

.

Components manufactured from galvanised sheet steel

have been painted to ensure their resistance to corrosion.

Any scratches, dents or similar on them must be repaired to

prevent corrosion.

9.1. Voltage indicator test

To test the

ekor

.ivds voltage presence indicator, connect

it to a 230 V

ac

power supply. To do this, disconnect the

ekor

.ivds device from the cubicle, and, using 4 mm cable

connectors, apply the voltage between the test point for

the phase to be checked and the earth test point.

No polarity is defi ned for 230 V

ac

, so either the phase or

neutral conductor can be connected.

If a fl ashing signal is observed, the device is working

correctly. In order to test the

ekor

.ivds correctly, this check

should be carried in the three phases.

Voltage presence indication is not suffi cient in itself

to ensure that the facility has been disconnected

from the electricity supply. Before accessing the cable

compartments, it is necessary to confi rm that the

feeder is connected to earth.

The

ekor

.ivds voltage indicator can be replaced if

necessary. To do so, loosen to release the two screws on

the top right and bottom left of the indicating relay using

a medium-size Phillips screwdriver. The

ekor

.ivds unit

can then be disconnected from the base without needing

to remove the power.

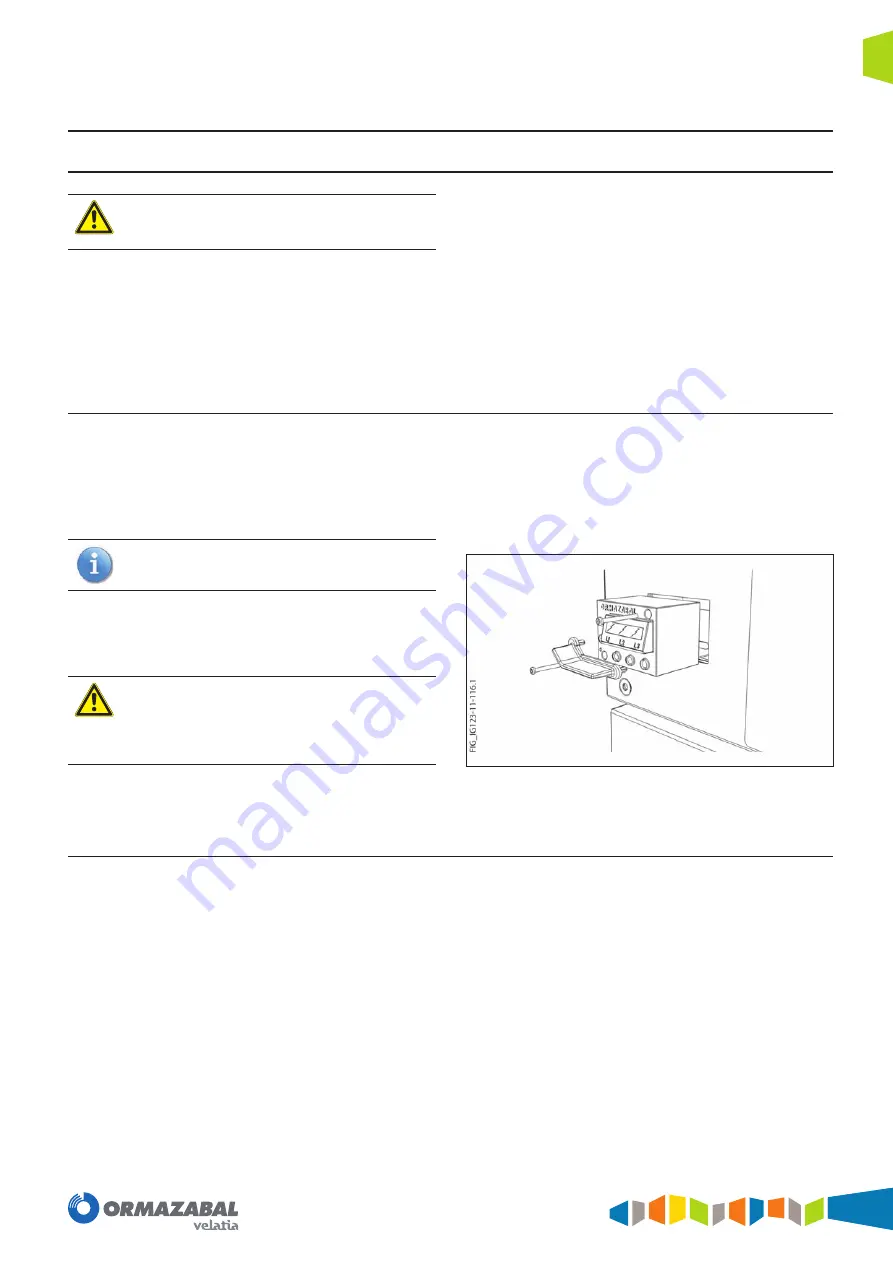

Figure 9.1.

Connection mode

ekor

.ivds

9.2. Preventive maintenance of circuit-breakers

The driving mechanisms and other elements outside

the gas tank may require preventive maintenance; the

frequency of this maintenance depends on the existing

environmental conditions (harsh environments, dust,

extreme temperatures, etc.) and must be established in line

with the experience and responsibility of the installer.

Preventive maintenance should be carried out every 5 years

or 2000 operating cycles, unless the user, together with

Ormazabal

, considers otherwise based on the operating

conditions.

Summary of Contents for velatia cpg.0

Page 79: ......