CONNECTION OF CONTROLS

Ventilators

MODEL

ODD-ERV-80 | ODD-ERV-120

Instruction Manual

1-888-543-6473

1-888-541-6474

13376 Comber Way

Surrey BC V3W 5V9

info@ortechindustries.com

www.ortechindustries.com

375 Admiral Blvd

Missis

s

auga

,

ON L5T 2N1

Speed Setting

The control system enables equal speed settings or synchronous

speed correcting for the supply and extract fan. (see

ALL

)

If the air resistance differential in the supply and extract air ducts

the speed of the supply and extract fan can be individually adjusted

and this setting will be saved in the controller memory (see

SPL

and

Eht

, respectively).

The controller circuit board has a digital indicator and <KEY1>,

<KEY2>, <KEY3> buttons which are used for operation mode setup

and editing of the operation parameters. After switching on power,

the ventilation unit operates normally and the light indicator is off.

Press <KEY1> to open the setup menu. Select the required menu

item using the buttons <KEY2> and <KEY3>. The display shows the

current setting of the menu item.

OPERATION MODES

<

Eht

>: set air flow for the active speed in the extract air duct in

CFM in the range from 40 CFM up to 120 CFM. For instance, in case

of activated HIGH speed, the changes establish new air flow in the

extract air duct. The new value will be a set air flow value for the

HIGH speed in the extract air duct. To display or change the value,

turn on the required speed (<LOW>, <MEDIUM> or <HIGH>), press

the <KEY1> button and set the required value for the air flow in

the extract air duct using the <KEY2> and <KEY3> buttons. Press

the <KEY1> button to save the value in the non-volatile memory

and return to the setup menu.

<

ALL

>: set air flow for the active speed both in the supply and

extract air ducts in CFM in the range from 40CFM up to 120CFM.

The set air flow is displayed according to the previous air flow

settings in the supply air duct for the active speed. For instance, in

case of activated LOW speed, the changes establish new air flow

both in the supply and extract air ducts synchronously. The new

value will be a set air flow value for the LOW speed in the supply

and extract air duct. To display or change the value, turn on the

required speed (<LOW>, <MEDIUM> or <HIGH>), press the <KEY1>

button and set the required value for the air flow in the supply and

extract air ducts using the <KEY2> and <KEY3> buttons. Press the

<KEY1> button to save the value in the non-volatile memory and

return to the setup menu.

<

SPL

>: set air flow for the active speed in the supply air duct in CFM in the range from 40CFM up to 120 CFM. For instance, in case of activated

MEDIUM speed, the changes establish new air flow in the supply air duct. The new value will be a set air flow value for the MEDIUM speed in

the supply air duct. To display or change the value, turn on the required speed (<LOW>, <MEDIUM> or <HIGH>), press the <KEY1> button and

set the required value for the air flow in the supply air duct using the <KEY2> and <KEY3> buttons. Press the <KEY1> button to save the value in

the non-volatile memory and return to the setup menu.

<

dEF

>:

reset to the factory settings (default settings). To reset to

the factory settings, press <KEY1>, then select <-Y-> using the

<KEY2> and <KEY3> buttons and press the <KEY1> button. To edit

the factory settings, select the <-n-> value using the <KEY2> and

<KEY3> buttons and press the <KEY1> button. The ventilation unit

revers to the manual settings.

<

Cor

>: Temperature corrections. To correct the temperature value

communicated by the temperature sensor, press the <KEY1>

button, change the temperature set point using the <KEY2> and

<KEY3> buttons, then press the <KEY1> button.

<

Prg

> software version. Press the <KEY1> button to display it.

In case of alarm, the alarm message <Err> is displayed. To detect

the alarm root, press the <KEY1> button and review the list of all

alarm messages using the <KEY2> and <KEY3> buttons. The alarm

message consists of a number (1, 2, 3) and a letter (n, Y). The

number determines the alarm message type.

1.

Fire alarm activation

2.

Temperature sensor short circuit

3.

Temperature sensor breakout

The letter indicates no alarm (n) or available alarm (Y).

Examples:

•

<1-Y>: fire alarm activation. If the fire alarm panel is

disconnected, it means that the controller contacts 31 and 32

are not jumpered.

•

<2-Y>: temperature sensor short circuit

•

<3-n>: no temperature sensor breakout

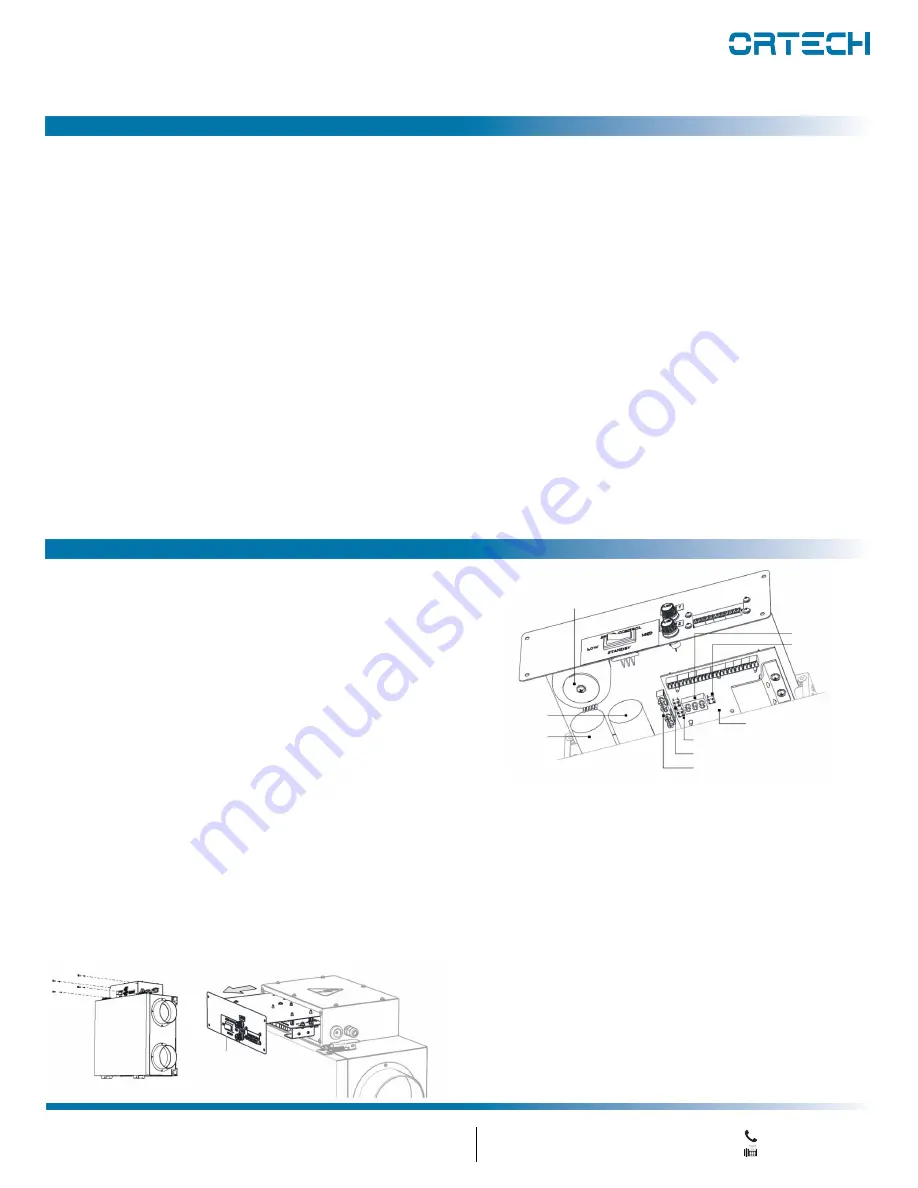

Access to the control circuit board and location of the indicator

and control buttons.

TR1 power transformer

C2 capacitor

C1 capacitor

HL1 light indicator

KEY1 button

Controller

KEY2 button

KEY3 button

X2 earth terminal block