20

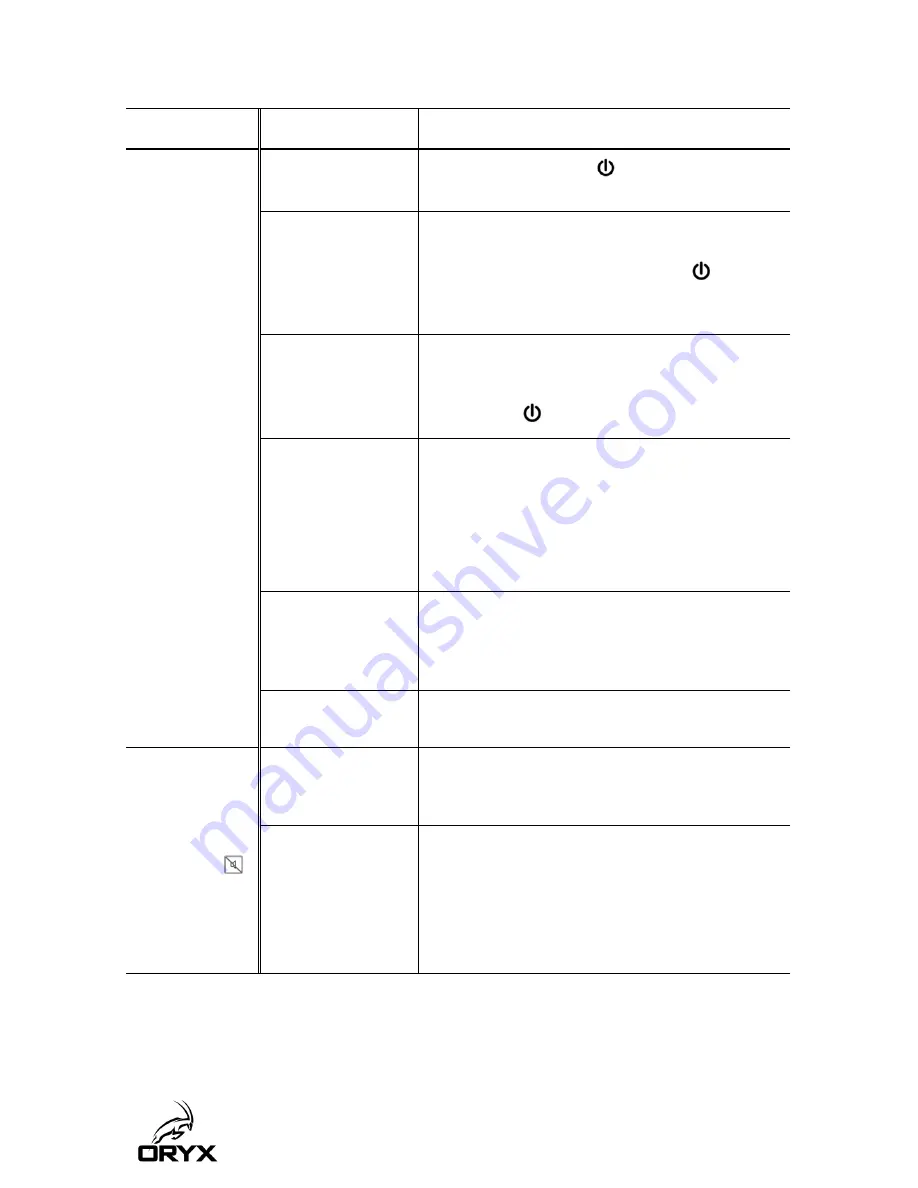

Problem

Probable Causes

What to Do

heater will not

start

panel. If it is off press the

button. If still unlit, then

proceed to the “Power Indicator is not Lit” Problem.

Timer has not been

set and started

The system will only run when the timer is counting

down. Check the timer display on the control panel.

•

If it is not counting down, press the

button.

•

If the time being displayed is 00:00, then add time

and start the system.

Liquid level is too

high or too low

Check the indicator lights on the right side of the display

control panel. If either level indicator is on, add or

remove water from the tank until the indicator turns

off. Press the

button to restart.

Liquid temperature

is too high

Error Code:

EO = over

temperature

Check the indicator lights on the right side of the display

control panel. If the Alert light is on, open the lids and

lift the part basket from the tank.

Let the liquid cool and try starting the cycle again.

If it overheats a second time, contact technical support

Over-temperature

sensor has tripped

A resettable over-temperature sensor located on the

back wall of the tank turns off the unit if the

temperature of the bath exceeds 95

⁰

C. For instructions

on resetting this sensor, contact technical support.

Pump or Heater has

failed

Contact technical support.

Buzzer is going

off

Silence the

buzzer by

pressing the

button

Liquid level is too

high or too low

Check the indicator lights on the right side of the

control panel. If either level indicator is on, add or

remove water from the tank until the indicators go off.

Liquid temperature

is too high

Error Code:

EO = over

temperature

Check the indicator lights on the right side of the

control panel. If the Alert indicator is on, open the lids

and lift the parts basket from the tank.

Let the liquid cool and try starting the cycle again.

If it overheats a second time, contact technical support.

Summary of Contents for sca3600

Page 1: ......