SECTION 3 - CHASSIS & TURNTABLE

3121659

– JLG Lift –

3-19

3.3

RE-ALIGN TORQUE HUB INPUT COUPLING

This procedure applies to torque hubs with integral brakes:

Equipment Required

1.

Hydraulic power supply (hand pump) capable of pro-

ducing 200 psi (13.8 bar).

2.

Hydraulic fittings to adapt hydraulic supply to brake

release port on hub.

Procedure

1.

Using appropriate fittings, connect a line from hydraulic

power supply to brake port.

2.

Pressurize brake release port to 155 - 200 psi (10.6 -

13.8 bar) to release brake.

3.

Verify brake is released by rotating input coupling or

hub spindle. Once brake is released, input coupling is

free to re-align with drive motor.

4.

Install drive motor on hub. Release hydraulic pressure at

brake release port. Coupling remains in position.

5.

Disconnect hydraulic power supply and reconnect line

to brake release port.

3.4

DRIVE MOTOR

Description

Drive motors are low to medium power, two-position axial pis-

ton motors incorporating an integral servo piston. They are

designed for operation in open and closed circuit applications.

The standard control is a direct acting single line hydraulic

control. The integral servo piston controls motor displace-

ment.

Motors are spring biased to maximum displacement and

hydraulically shifted to minimum displacement. Minimum and

maximum displacement can be set with fixed internal stops.

The large diameter servo piston allows smooth acceleration

and deceleration with relatively large circuit orificing.

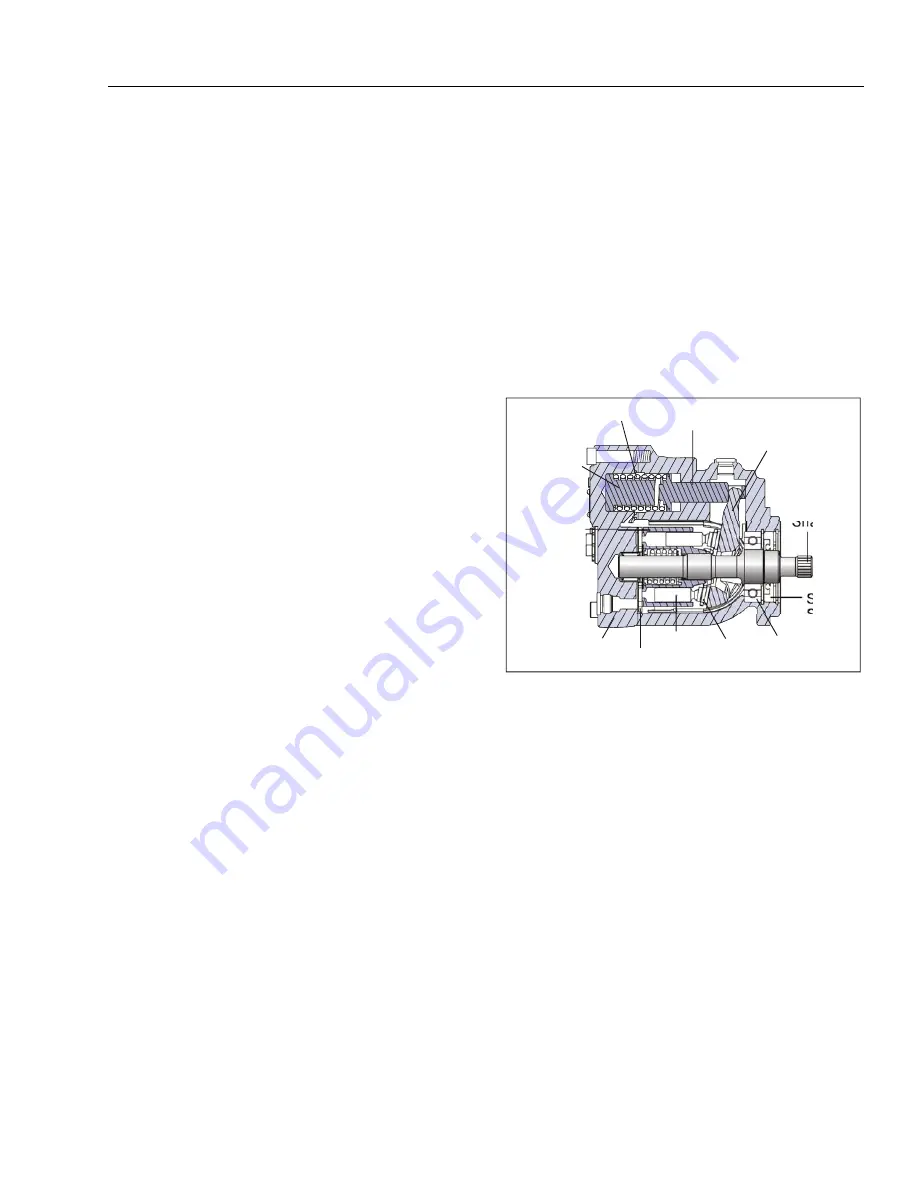

Figure 3-7. Drive Motor Cross Section

Bias spring

Servo piston

Swashplate

Output

Shaft

Piston

Slipper

Cylinder

Block

Endcap

Shaft

Seal

Bearing

Minimum

Angle

Stop

Valve plate

Summary of Contents for JLG 450AJ

Page 2: ......

Page 32: ...SECTION 1 SPECIFICATIONS 1 18 JLG Lift 3121659 NOTES...

Page 80: ...SECTION 4 BOOM PLATFORM 4 2 JLG Lift 3121659 Figure 4 1 Boom Assembly...

Page 81: ...SECTION 4 BOOM PLATFORM 3121659 JLG Lift 4 3 Figure 4 2 Main Boom Assembly Sheet 1 of 2...

Page 82: ...SECTION 4 BOOM PLATFORM 4 4 JLG Lift 3121659 Figure 4 3 Main Boom Assembly Sheet 2 of 2...

Page 83: ...SECTION 4 BOOM PLATFORM 3121659 JLG Lift 4 5 Figure 4 4 Upper Boom Assembly...

Page 84: ...SECTION 4 BOOM PLATFORM 4 6 JLG Lift 3121659 Figure 4 5 Jib Assembly...

Page 118: ...SECTION 4 BOOM PLATFORM 4 40 JLG Lift 3121659 NOTES...

Page 156: ...SECTION 5 BASIC HYDRAULIC INFORMATION HYDRAULIC SCHEMATICS 5 38 JLG Lift 3121659 NOTES...

Page 164: ...SECTION 6 JLG CONTROL SYSTEM 6 8 JLG Lift 3121659 Figure 6 2 Tilt Sensor Location...

Page 169: ...SECTION 6 JLG CONTROL SYSTEM 3121659 JLG Lift 6 13 Figure 6 7 Analyzer Connecting Points...

Page 181: ...SECTION 6 JLG CONTROL SYSTEM 3121659 JLG Lift 6 25 Figure 6 19 Platform Module Sheet 1 of 2...

Page 182: ...SECTION 6 JLG CONTROL SYSTEM 6 26 JLG Lift 3121659 Figure 6 20 Platform Module Sheet 2 of 2...

Page 224: ...SECTION 6 JLG CONTROL SYSTEM 6 68 JLG Lift 3121659 NOTES...

Page 340: ...SECTION 7 BASIC ELECTRICAL INFORMATION ELECTRICAL SCHEMATICS 7 116 JLG Lift 3121659 NOTES...

Page 341: ......