SECTION 7 - BASIC TROUBLESHOOTING, ELECTRICAL INFORMATION, & SCHEMATICS

7-2

– JLG Lift –

3121827

.

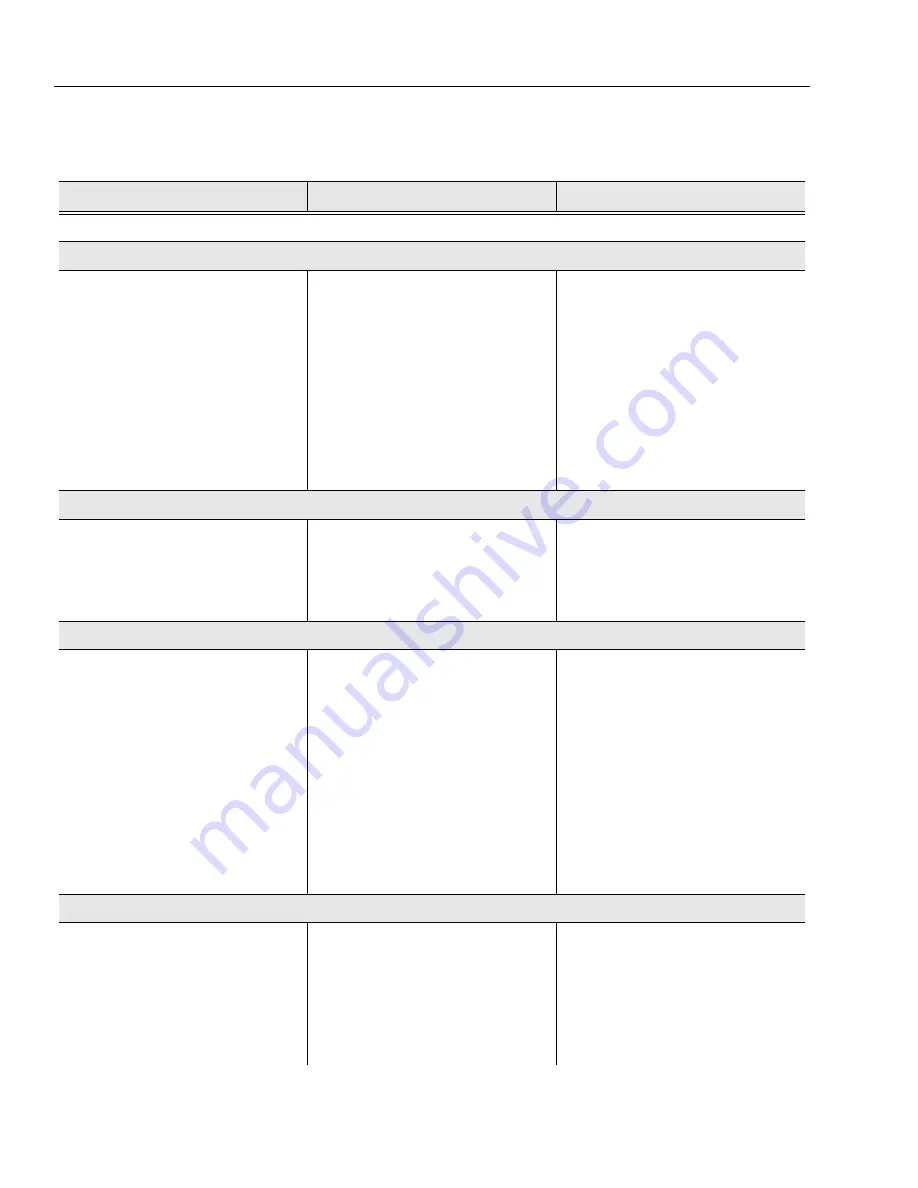

Table 7-1. Platform Assembly - Troubleshooting

TROUBLE

PROBABLE CAUSE

REMEDY

Automatic leveling inoperative.

Hydraulic system oil low.

Replenish oil as necessary.

Dual check valves dirty/inoperative.

Clean or replace as necessary.

Restricted or broken hydraulic line or fitting on

slave cylinder or main lift cylinder.

Clean, repair, or replace line or fitting.

Worn seal(s) in slave level or main lift cylinder.

Replace seal(s).

Counterbalance valve in slave cylinder defec-

tive.

Replace counterbalance valve.

Slave level or main lift cylinder not functioning

properly.

Slave level or main lift cylinder not functioning

properly.

Platform will not maintain level attitude.

Counterbalance valve on slave leveling cylinder

improperly adjusted or not functioning properly.

Replace valve.

Worn seal(s) in slave level or main lift cylinder.

Replace seal(s).

Damaged slave level or main lift cylinder.

Repair or replace cylinder.

No response to platform leveling controls.

Level function not activated within 7 seconds

after footswitch was depressed.

Recycle footswitch.

Level control switch inoperative.

Repair or replace control switch lever.

Hydraulic system oil low.

Replenish oil as necessary.

Proportional Flow Regulator not powered.

Wiring: Run System Test

Restricted or broken hydraulic line or fitting.

Clean, repair, or replace line or fitting.

Directional valve not functioning properly.

Repair or replace valve.

No electric power to directional control valve.

See proper wiring diagram/Run System Test.

Slave cylinder not functioning properly.

Repair or replace pump.

Platform will not adjust "up" or "down" to level.

Hydraulic pump not functioning properly.

Run System Test.

Restricted or broken hydraulic line or fitting.

Clean, repair, or replace line or fitting.

Slave cylinder not functioning properly.

Repair or replace cylinder.

Electrical failure.

See proper wiring diagram/Run System Test.

Orifice plugged.

Clean orifice.

Summary of Contents for JLG E400AJP

Page 2: ......

Page 32: ...SECTION 1 SPECIFICATIONS 1 18 JLG Lift 3121827 NOTES...

Page 42: ...SECTION 2 GENERAL 2 10 JLG Lift 3121827 NOTES...

Page 54: ...SECTION 3 CHASSIS TURNTABLE 3 12 JLG Lift 3121827 Figure 3 3 Speed Sensor Orientation...

Page 60: ...SECTION 3 CHASSIS TURNTABLE 3 18 JLG Lift 3121827 Figure 3 7 Steering Components and Spindles...

Page 62: ...SECTION 3 CHASSIS TURNTABLE 3 20 JLG Lift 3121827 Figure 3 9 Tilt Sensor Location...

Page 86: ...SECTION 3 CHASSIS TURNTABLE 3 44 JLG Lift 3121827 Figure 3 16 Swing Components...

Page 88: ...SECTION 3 CHASSIS TURNTABLE 3 46 JLG Lift 3121827 Figure 3 18 Battery Cable Connections...

Page 90: ...SECTION 3 CHASSIS TURNTABLE 3 48 JLG Lift 3121827 Figure 3 20 On Board Generator...

Page 97: ...SECTION 3 CHASSIS TURNTABLE 3121827 JLG Lift 3 55 Figure 3 22 Generator Components...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 74 JLG Lift 3121827 NOTES...

Page 127: ...SECTION 4 BOOM PLATFORM 3121827 JLG Lift 4 11 Figure 4 10 Boom Limit Switches...

Page 140: ...SECTION 4 BOOM PLATFORM 4 24 JLG Lift 3121827 Figure 4 13 Rotator Counterbalance Valve...

Page 178: ...SECTION 5 HYDRAULICS 5 24 JLG Lift 3121827 Figure 5 26 HydraForce Cartridge Torque Value Chart...

Page 214: ...SECTION 6 JLG CONTROL SYSTEM 6 34 JLG Lift 3121827 NOTES...

Page 257: ......