SECTION 3 - CHASSIS & TURNTABLE

3-10

– JLG Lift –

3121827

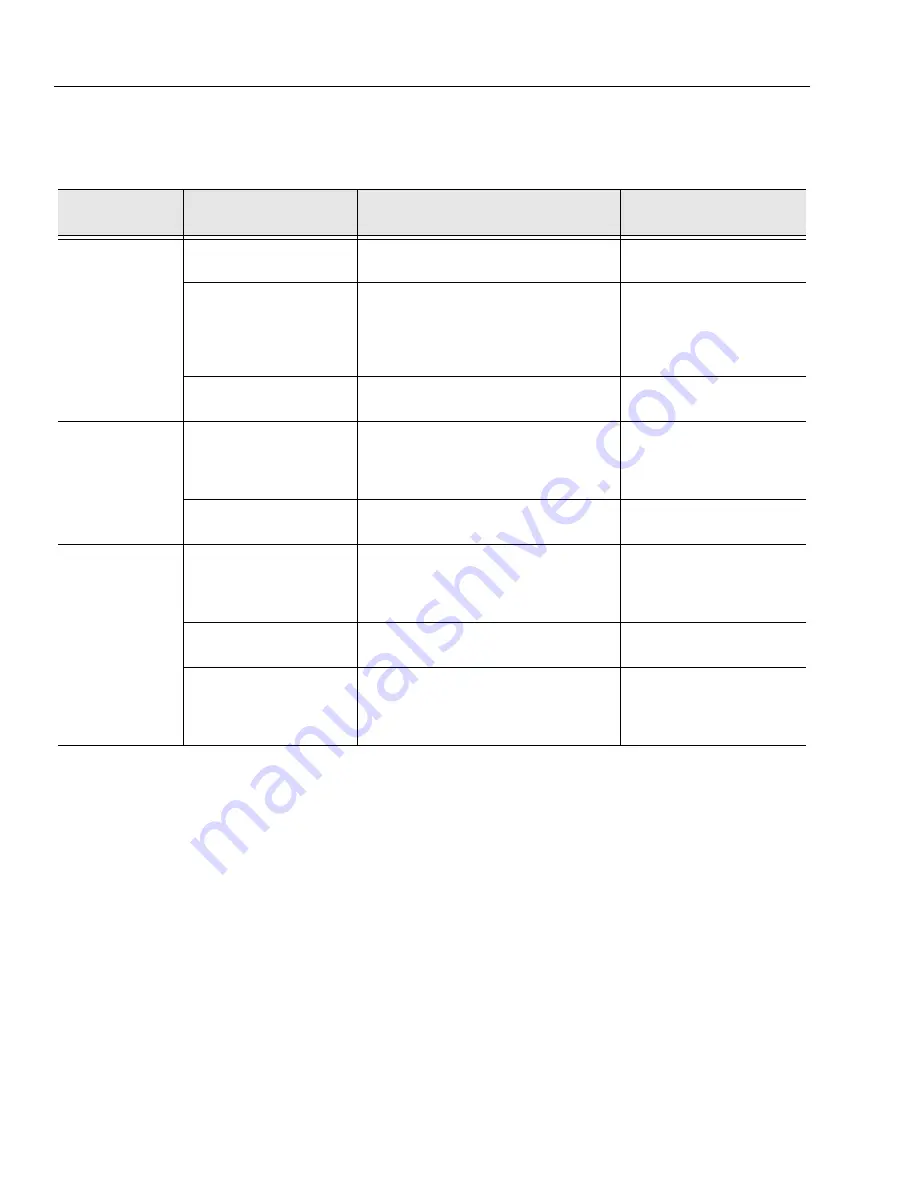

Table 3-2. Drive Brake Diagnosis

Problem

Cause

Explanation

Corrective

Action

Brake slips

Excessive pressure In hydraulic

system

If there is back pressure in the actuation line of the

brake, holding torque will be reduced.

Check filters. hose size, restrictions

in other hydraulic components.

Oil In brake if designed for dry

use

Wet linings generate 67% of the dry torque rating. If

the brake has oil In it, check the type of oil hydraulic

or gearbox.

1. Gearbox oil

2. Hydraulic oil

Replace oil seal in brake. Check

motor seal. Check piston seals.

Note: Internal components will

need to be inspected, cleaned, and

replaced as required.

Springs broken or have taken a

permanent set

Broken or set springs can cause reduced torque -

rare occurrence.

See spring replacement

Brake drags or runs

hot

Low actuation pressure

The brake should be pressurized to minimum of

1.38 bar (20 psi) over the full release pressure under

normal operating conditions. Lower pressures will

cause the brake to drag thus generating heat.

Place pressure gauge in bleed port

& check pressure with system on.

Bearing failure

If the bearing should fall. a large amount of drag can

be generated.

Replace bearing.

Brake will not release

Stuck or clogged valve

Brakes are designed to come on when system pres-

sure drops below stated release pressure. If pres-

sure cannot get to brake, the brake will not release.

Place pressure gauge in bleed port

- check for adequate pressure.

Replace defective line or compo-

nent.

Bad o-rings

Release piston will not hold pressure, brake will not

release.

Replace o-rings.

Discs frozen

These brakes are designed for only limited dynamic

braking. A severe emergency stop or prolonged

reduced release pressure operation may result in

this type of damage.

Replace disc stack.

Summary of Contents for JLG E400AJP

Page 2: ......

Page 32: ...SECTION 1 SPECIFICATIONS 1 18 JLG Lift 3121827 NOTES...

Page 42: ...SECTION 2 GENERAL 2 10 JLG Lift 3121827 NOTES...

Page 54: ...SECTION 3 CHASSIS TURNTABLE 3 12 JLG Lift 3121827 Figure 3 3 Speed Sensor Orientation...

Page 60: ...SECTION 3 CHASSIS TURNTABLE 3 18 JLG Lift 3121827 Figure 3 7 Steering Components and Spindles...

Page 62: ...SECTION 3 CHASSIS TURNTABLE 3 20 JLG Lift 3121827 Figure 3 9 Tilt Sensor Location...

Page 86: ...SECTION 3 CHASSIS TURNTABLE 3 44 JLG Lift 3121827 Figure 3 16 Swing Components...

Page 88: ...SECTION 3 CHASSIS TURNTABLE 3 46 JLG Lift 3121827 Figure 3 18 Battery Cable Connections...

Page 90: ...SECTION 3 CHASSIS TURNTABLE 3 48 JLG Lift 3121827 Figure 3 20 On Board Generator...

Page 97: ...SECTION 3 CHASSIS TURNTABLE 3121827 JLG Lift 3 55 Figure 3 22 Generator Components...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 74 JLG Lift 3121827 NOTES...

Page 127: ...SECTION 4 BOOM PLATFORM 3121827 JLG Lift 4 11 Figure 4 10 Boom Limit Switches...

Page 140: ...SECTION 4 BOOM PLATFORM 4 24 JLG Lift 3121827 Figure 4 13 Rotator Counterbalance Valve...

Page 178: ...SECTION 5 HYDRAULICS 5 24 JLG Lift 3121827 Figure 5 26 HydraForce Cartridge Torque Value Chart...

Page 214: ...SECTION 6 JLG CONTROL SYSTEM 6 34 JLG Lift 3121827 NOTES...

Page 257: ......