SECTION 3 - CHASSIS & TURNTABLE

3-24

– JLG Lift –

3121827

Preparation Before Disassembly

• Before you disassemble the motor unit or any of its

components read this entire section. It provides impor-

tant information on parts and procedures you will need

to know to service the motor.

• Thoroughly clean off all outside dirt, especially from

around fittings and hose connections, before discon-

necting and removing the motor. Remove rust or corro-

sion from coupling shaft.

• Remove coupling shaft connections and hose fittings

and immediately plug port holes and fluid lines.

• Remove the motor from system, drain it of fluid and

take it to a clean work surface.

• Clean and dry the motor before you start to disassem-

ble the unit.

• As you disassemble the motor clean all parts, except

seals, in clean petroleum-based solvent, and blow

them dry.

PETROLEUM-BASE SOLVENTS ARE FLAMMABLE. BE EXTREMELY

CAREFUL WHEN USING ANY SOLVENT. EVEN A SMALL EXPLO-

SION OR FIRE COULD CAUSE INJURY OR DEATH.

WEAR EYE PROTECTION AND BE SURE TO COMPLY WITH OSHA

OR OTHER MAXIMUM AIR PRESSURE REQUIREMENTS.

NEVER STEAM OR HIGH PRESSURE WASH HYDRAULIC COMPO-

NENTS. DO NOT FORCE OR ABUSE CLOSELY FITTED PARTS.

• Keep parts separate to avoid nicks and burrs.

• Discard all seals and seal rings as they are removed

from the motor. Replace all seals, seal rings and any

damaged or worn parts with OEM approved service

parts.

Disassembly and Inspection

1.

Place the motor in a soft jawed vice, with coupling

shaft (12) pointed down and the vise jaws clamping

firmly on the sides of the housing (18) mounting

flange or port bosses. Remove manifold port O-

Rings if applicable.

IF THE MOTOR IS NOT FIRMLY HELD IN THE VISE, IT COULD BE

DISLODGED DURING THE SERVICE PROCEDURES, CAUSING

INJURY.

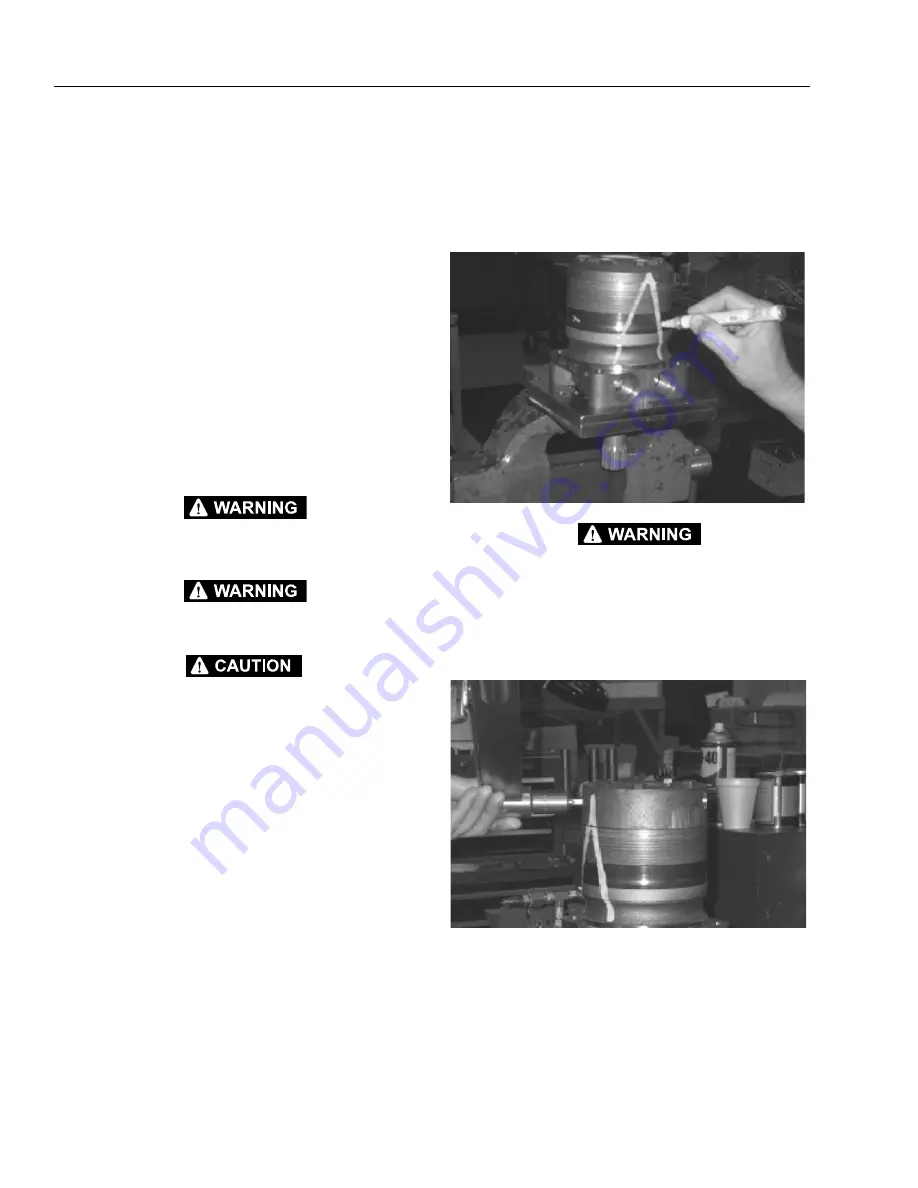

2.

Scribe an alignment mark down and across the

motor components from end cover (2) to housing

(18) to facilitate reassembly orientation where

required.

Summary of Contents for JLG E400AJP

Page 2: ......

Page 32: ...SECTION 1 SPECIFICATIONS 1 18 JLG Lift 3121827 NOTES...

Page 42: ...SECTION 2 GENERAL 2 10 JLG Lift 3121827 NOTES...

Page 54: ...SECTION 3 CHASSIS TURNTABLE 3 12 JLG Lift 3121827 Figure 3 3 Speed Sensor Orientation...

Page 60: ...SECTION 3 CHASSIS TURNTABLE 3 18 JLG Lift 3121827 Figure 3 7 Steering Components and Spindles...

Page 62: ...SECTION 3 CHASSIS TURNTABLE 3 20 JLG Lift 3121827 Figure 3 9 Tilt Sensor Location...

Page 86: ...SECTION 3 CHASSIS TURNTABLE 3 44 JLG Lift 3121827 Figure 3 16 Swing Components...

Page 88: ...SECTION 3 CHASSIS TURNTABLE 3 46 JLG Lift 3121827 Figure 3 18 Battery Cable Connections...

Page 90: ...SECTION 3 CHASSIS TURNTABLE 3 48 JLG Lift 3121827 Figure 3 20 On Board Generator...

Page 97: ...SECTION 3 CHASSIS TURNTABLE 3121827 JLG Lift 3 55 Figure 3 22 Generator Components...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 74 JLG Lift 3121827 NOTES...

Page 127: ...SECTION 4 BOOM PLATFORM 3121827 JLG Lift 4 11 Figure 4 10 Boom Limit Switches...

Page 140: ...SECTION 4 BOOM PLATFORM 4 24 JLG Lift 3121827 Figure 4 13 Rotator Counterbalance Valve...

Page 178: ...SECTION 5 HYDRAULICS 5 24 JLG Lift 3121827 Figure 5 26 HydraForce Cartridge Torque Value Chart...

Page 214: ...SECTION 6 JLG CONTROL SYSTEM 6 34 JLG Lift 3121827 NOTES...

Page 257: ......