SECTION 7 - BASIC TROUBLESHOOTING, ELECTRICAL INFORMATION, & SCHEMATICS

7-22

– JLG Lift –

3121827

Automatic Switches

If the switch is actuated automatically, by temperature or

pressure for example, find a way to manually actuate the

switch to test it. Do this either by applying heat or pres-

sure, for example, to the switch. These switches may need

to be energized to actuate.

1. Connect instrumentation to monitor and/or control

the parameter the switch is measuring.

2. Observe switch state in control system with the Ana-

lyzer. See vehicle or control system documentation

on how to do this.

3. Operate system such that the switch actuates. This

could be going over a certain pressure or tempera-

ture, for example. The state indicated in the control

system should change.

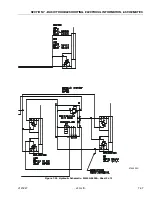

Switch Wiring - Low Side, High Side

When controlling a load, a switch can be wired between

the positive side of the power source and the load. This

switch is called a "high side" switch. The switch supplies

the power to the load. When a switch is wired between the

negative side of the power source and the load, it is a "low

side" switch. The switch provides the ground to the load.

A low side switch will allow voltage to be present on the

load. No power is applied because the switch is stopping

current flow. This voltage can be seen if the measurement

is taken with one test lead on the load and the other on

the battery negative side or grounded to the vehicle. What

is actually being measured is the voltage drop across the

switch. This could mislead a technician into thinking the

load is receiving power but not operating. To produce an

accurate picture of power or voltage applied to the load,

measure voltage across the load’s power terminals. Also,

the technician can measure the voltage at both power ter-

minals with respect to battery ground. The difference

between those two measurements is the voltage applied

to the load.

7.5 APPLYING SILICONE DIELECTRIC

COMPOUND TO ELECTRICAL

CONNECTIONS

NOTE:

Do NOT apply dielectric grease to the following con-

nections:

• Main Boom Rotary sensor connections (on Celesco

Sensor),

• LSS Modules connections,

• Deutz EMR 2 ECM connection.

Silicone Dielectric Compound must be used on all electri-

cal connections except for those mentioned above for the

following reasons:

• To prevent oxidation at the mechanical joint between

male and female pins.

• To prevent electrical malfunction caused by low level

conductivity between pins when wet.

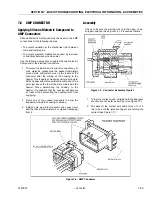

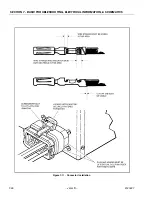

Use the following procedure to apply Silicone Dielectric

Compound to the electrical connectors. This procedure

applies to all plug connections not enclosed in a box. Sili-

cone grease should not be applied to connectors with

external seals.

1. To prevent oxidation, silicone grease must be

packed completely around male and female pins on

the inside of the connector prior to assembly. This is

most easily achieved by using a syringe.

NOTE:

Over a period of time, oxidation increases electrical

resistance at the connection, eventually causing cir-

cuit failure.

2. To prevent shorting, silicone grease must be packed

around each wire where they enter the outside of the

connector housing. Also, silicone grease must be

applied at the joint where the male and female con-

nectors come together. Any other joints (around

strain reliefs, etc.) where water could enter the con-

nector should also be sealed.

NOTE:

This condition is especially common when machines

are pressure washed since the washing solution is

much more conductive than water.

3. Silicone grease should be applied at the time and

location of the final connection of the pins into the

housings, and plugs into receptacles. This will mini-

mize exposure to the elements as a lubricated (wet)

connector.

4. Anderson connectors for the battery boxes and bat-

tery chargers should have silicone grease applied to

the contacts only.

NOTE:

Curing-type sealants might also be used to prevent

shorting and would be less messy, but would make

future pin removal more difficult.

Summary of Contents for JLG E400AJP

Page 2: ......

Page 32: ...SECTION 1 SPECIFICATIONS 1 18 JLG Lift 3121827 NOTES...

Page 42: ...SECTION 2 GENERAL 2 10 JLG Lift 3121827 NOTES...

Page 54: ...SECTION 3 CHASSIS TURNTABLE 3 12 JLG Lift 3121827 Figure 3 3 Speed Sensor Orientation...

Page 60: ...SECTION 3 CHASSIS TURNTABLE 3 18 JLG Lift 3121827 Figure 3 7 Steering Components and Spindles...

Page 62: ...SECTION 3 CHASSIS TURNTABLE 3 20 JLG Lift 3121827 Figure 3 9 Tilt Sensor Location...

Page 86: ...SECTION 3 CHASSIS TURNTABLE 3 44 JLG Lift 3121827 Figure 3 16 Swing Components...

Page 88: ...SECTION 3 CHASSIS TURNTABLE 3 46 JLG Lift 3121827 Figure 3 18 Battery Cable Connections...

Page 90: ...SECTION 3 CHASSIS TURNTABLE 3 48 JLG Lift 3121827 Figure 3 20 On Board Generator...

Page 97: ...SECTION 3 CHASSIS TURNTABLE 3121827 JLG Lift 3 55 Figure 3 22 Generator Components...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 74 JLG Lift 3121827 NOTES...

Page 127: ...SECTION 4 BOOM PLATFORM 3121827 JLG Lift 4 11 Figure 4 10 Boom Limit Switches...

Page 140: ...SECTION 4 BOOM PLATFORM 4 24 JLG Lift 3121827 Figure 4 13 Rotator Counterbalance Valve...

Page 178: ...SECTION 5 HYDRAULICS 5 24 JLG Lift 3121827 Figure 5 26 HydraForce Cartridge Torque Value Chart...

Page 214: ...SECTION 6 JLG CONTROL SYSTEM 6 34 JLG Lift 3121827 NOTES...

Page 257: ......