SECTION 3 - CHASSIS & TURNTABLE

3-2

– JLG Lift –

3121827

2.

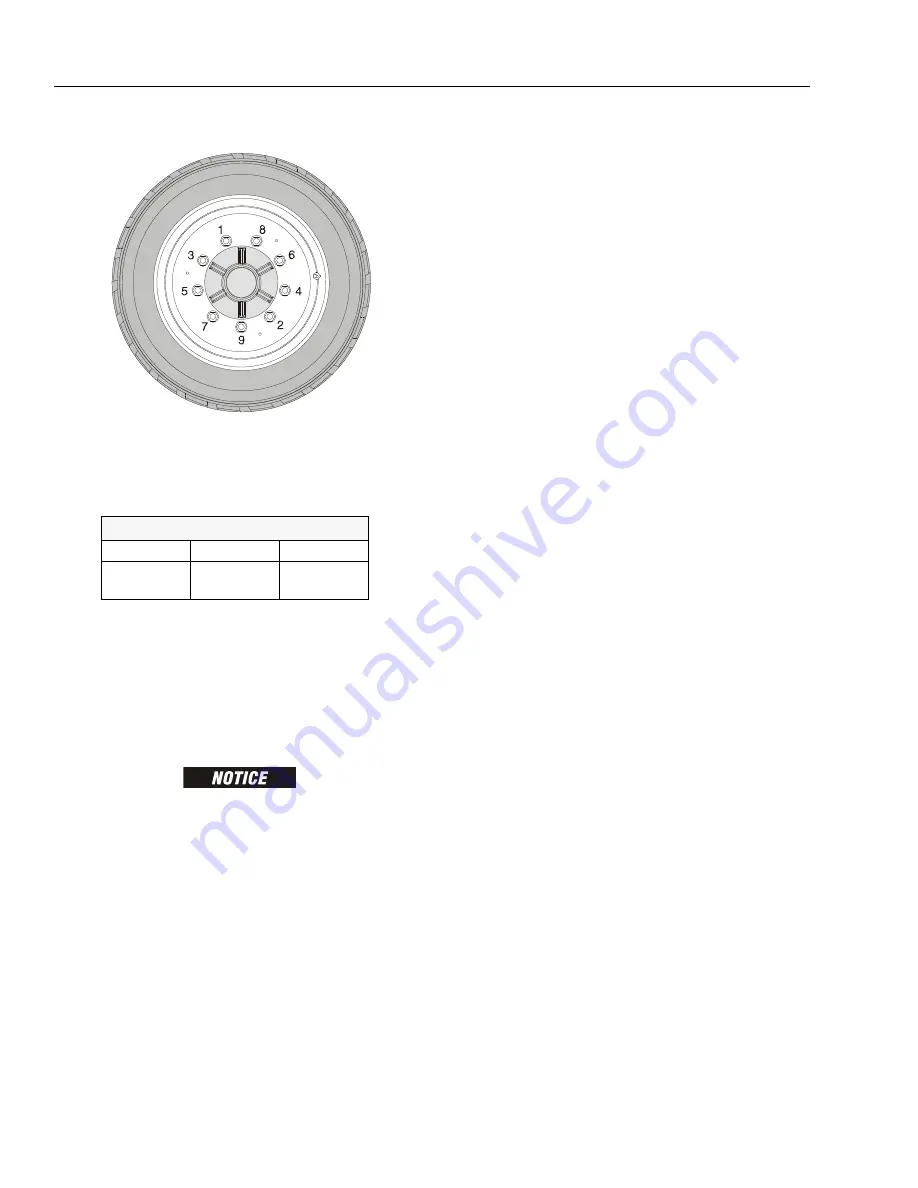

Tighten nuts in the following sequence:

3.

The tightening of the nuts should be done in stages.

Following the recommended sequence, tighten nuts

per wheel torque chart.

4.

Wheel nuts should be torqued after first 50 hours of

operation and after each wheel removal. Check

torque every 3 months or 150 hours of operation.

3.2 SPINDLE

Setting Wheel Bearing End Play

BE SURE NOT TO OVER-TIGHTEN THE SPINDLE NUT.

1.

Tighten the spindle nut to assure the bearings are

properly seated.

2.

Loosen the spindle nut completely until the nut can

be turned by hand.

3.

Tighten the spindle nut by hand using a socket with-

out rotating the hub.

4.

If the cotter pin can be assembled with the spindle

nut finger tight, insert cotter pin without backing the

nut off. If the cotter pin cannot be assembled with

the spindle nut hand tight, tighten the spindle nut to

the nearest available slot and insert cotter pin. If

more than ½ of the cotter pin hole in the spindle can

be seen in a slot, back nut off to nearest slot and

insert pin.

5.

Check the unit for end play by moving the hub up &

down parallel along the centerline of the spindle. If

you can feel excessive end play (over the 0.010"

[0.25 mm] specification), recheck the nut to see

what is causing the excessive end play. Keep in

mind that there can be some movement and still be

within the 0.010" (0.25 mm) maximum specification.

If there is no way of getting the excessive end play

out by using your fingers, a socket or wrench may

have to be used to set the end play.

6.

The units should be checked visually to make sure

the cotter pins are installed and that the correct

components have been used. Each unit must also

be checked for the proper feel to make sure there

isn’t excessive end play and the hubs turn freely.

7.

Insert the dust cap and check to make sure the cot-

ter pin is not going to interfere. Cap must be pressed

all the way down. The unit should be checked again

to assure it spins freely after the dust cap is installed.

Specifications

The end play specification is 0.001”/0.010" (0.025 / 0.254

mm) for all units.

Checking

The end play is checked by clamping the spindle in a fix-

ture or vise and moving the hub parallel to the spindle

centerline without rocking the hub. If the end play is set

properly the following should apply:

1.

Hub should rotate freely when spun by hand.

2.

The hub should not be noticeably loose when

moved parallel with spindle centerline.

Greasing Requirements

Hub assemblies shall have grease packed in the bearings

via an appropriate greasing spindle or by hand. In either

method, the bearing must be greased so the grease is

forced thru the entire bearing cavity and thru the rollers of

both inner and outer bearings.

Dust or grease caps used shall have grease applied to the

inside of the cap.

The bearing cavity shall be filled 50 - 80% full of grease on

all applications.

Dust or grease caps shall also be filled 10-20% full of

grease on all applications prior to final assembly.

Visually verify that grease has flowed thru all rollers of the

inner and outer bearings.

Table 3-1. Wheel Torque Chart

TORQUE SEQUENCE

1st Stage

2nd Stage

3rd Stage

40 ft. lbs.

(55 Nm)

100 ft. lbs.

(130 Nm)

170 ft. lbs.

(255 Nm)

Summary of Contents for JLG E400AJP

Page 2: ......

Page 32: ...SECTION 1 SPECIFICATIONS 1 18 JLG Lift 3121827 NOTES...

Page 42: ...SECTION 2 GENERAL 2 10 JLG Lift 3121827 NOTES...

Page 54: ...SECTION 3 CHASSIS TURNTABLE 3 12 JLG Lift 3121827 Figure 3 3 Speed Sensor Orientation...

Page 60: ...SECTION 3 CHASSIS TURNTABLE 3 18 JLG Lift 3121827 Figure 3 7 Steering Components and Spindles...

Page 62: ...SECTION 3 CHASSIS TURNTABLE 3 20 JLG Lift 3121827 Figure 3 9 Tilt Sensor Location...

Page 86: ...SECTION 3 CHASSIS TURNTABLE 3 44 JLG Lift 3121827 Figure 3 16 Swing Components...

Page 88: ...SECTION 3 CHASSIS TURNTABLE 3 46 JLG Lift 3121827 Figure 3 18 Battery Cable Connections...

Page 90: ...SECTION 3 CHASSIS TURNTABLE 3 48 JLG Lift 3121827 Figure 3 20 On Board Generator...

Page 97: ...SECTION 3 CHASSIS TURNTABLE 3121827 JLG Lift 3 55 Figure 3 22 Generator Components...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 74 JLG Lift 3121827 NOTES...

Page 127: ...SECTION 4 BOOM PLATFORM 3121827 JLG Lift 4 11 Figure 4 10 Boom Limit Switches...

Page 140: ...SECTION 4 BOOM PLATFORM 4 24 JLG Lift 3121827 Figure 4 13 Rotator Counterbalance Valve...

Page 178: ...SECTION 5 HYDRAULICS 5 24 JLG Lift 3121827 Figure 5 26 HydraForce Cartridge Torque Value Chart...

Page 214: ...SECTION 6 JLG CONTROL SYSTEM 6 34 JLG Lift 3121827 NOTES...

Page 257: ......