SECTION 4 - BOOM & PLATFORM

4-20

– JLG Lift –

3121623

4.6

BOOM ROTATION SENSOR ASSEMBLY - X23JP -

X700AJ

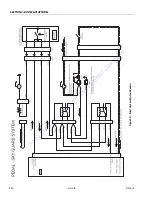

1.

Assemble the end couplings (p/n-26741500)

using the hex galvanized screws (p/n-BV013000)

to the extension pipe (p/n-06745900).

Figure 4-26.

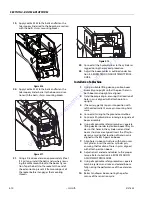

2.

Locate the rotation sensor (encoder) (p/n-

0660400) and encoder coupling (p/n-26741500).

Figure 4-27.

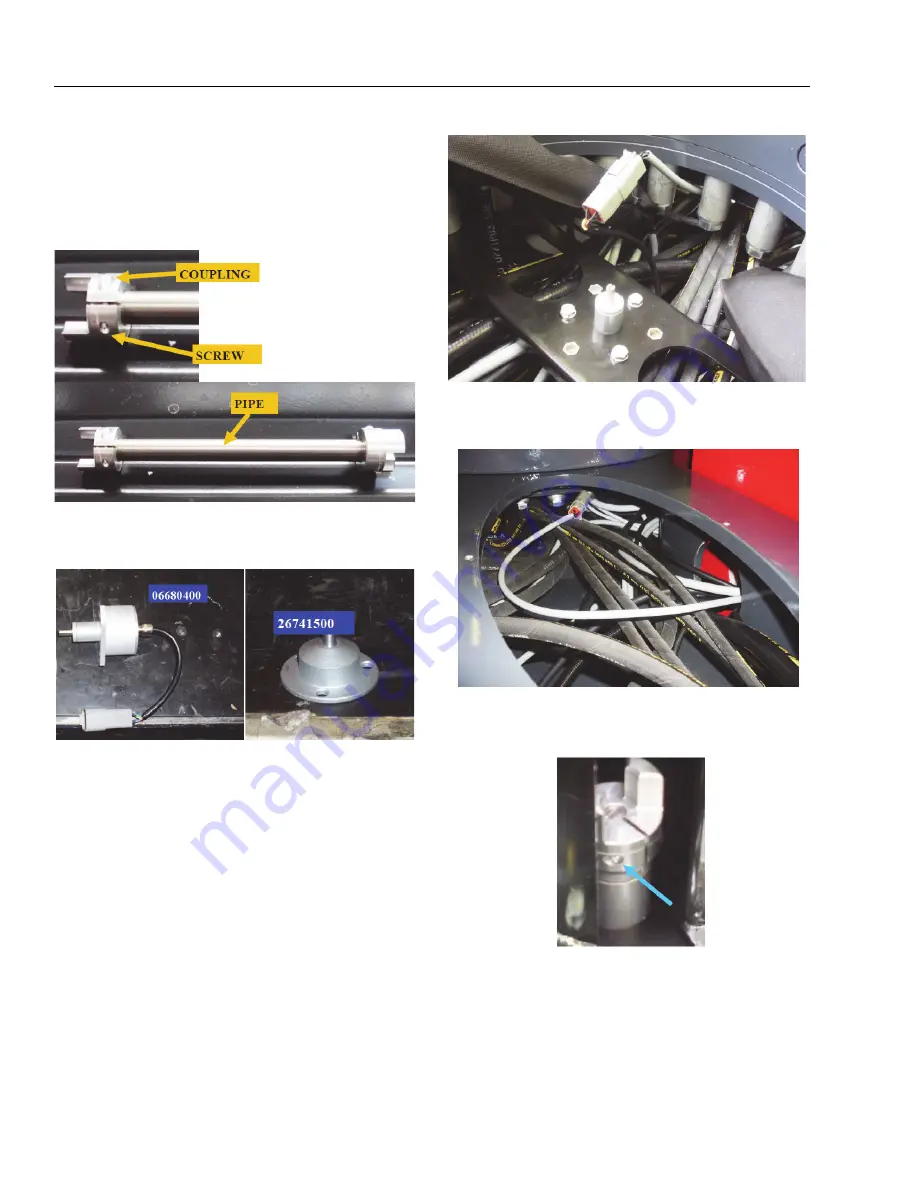

3.

Mount the rotation sensor (encoder) to the

crossmember under the turntable bearing using

3 - 6 x 12M screws with threadlocker. Connect

the rotation sensor electrical connector to the

connector coming from the electrical box.

Figure 4-28.

4.

Route the rotation sensor electrical cable inside

the frame as shown below.

Figure 4-29.

5.

Install a coupling onto the rotation sensor shaft

using 1 - 3x12M screw (p/n-BV013000).

Figure 4-30.

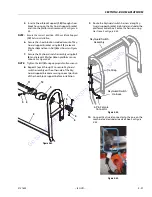

6.

Install the protective cover over the rotation sen-

sor assembly using 3-6x16M TE screws and

washers. Install cover with the open slot facing

the engine end of the machine.

Go to

Discount-Equipment.com

to

order your

parts