Optical Scientific Inc

OFS 2000CW User’s Guide

P/N 1910-905

Rev. 03/28/13

21

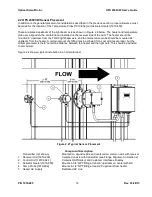

3.4 Purge Air

The OFS 2000CW, being an optical measuring device,

needs to “see” clearly. The function of purge air is to keep

the interior atmosphere of the mounting nozzle clear, the

light path unobstructed, and provide an air barrier to slow

the rate of deposition on the window. (In cases of high flue

gas temperatures the purge can also prevent hot gases

from entering the nozzle.)

There are two methods of supplying purge air: Passive

and Active

Passive Purge

In applications where the internal pressure is

approximately negative 3 inches (WC) or more, and unchanging, then the purge fittings can be removed and

the natural inflow of outside air through the open holes themselves may be used to keep the light path clear.

NOTE:

This is no longer recommended as best practice. Passive purge can be effective and has been adapted by

users wishing to economize on extra equipment. It has been found to work adequately, but due to the

incidence of problems occurring from misapplication, and/or lack of control, it's use is not encouraged. The use

of Active Purge, as described herein, is recommended for optimum results.

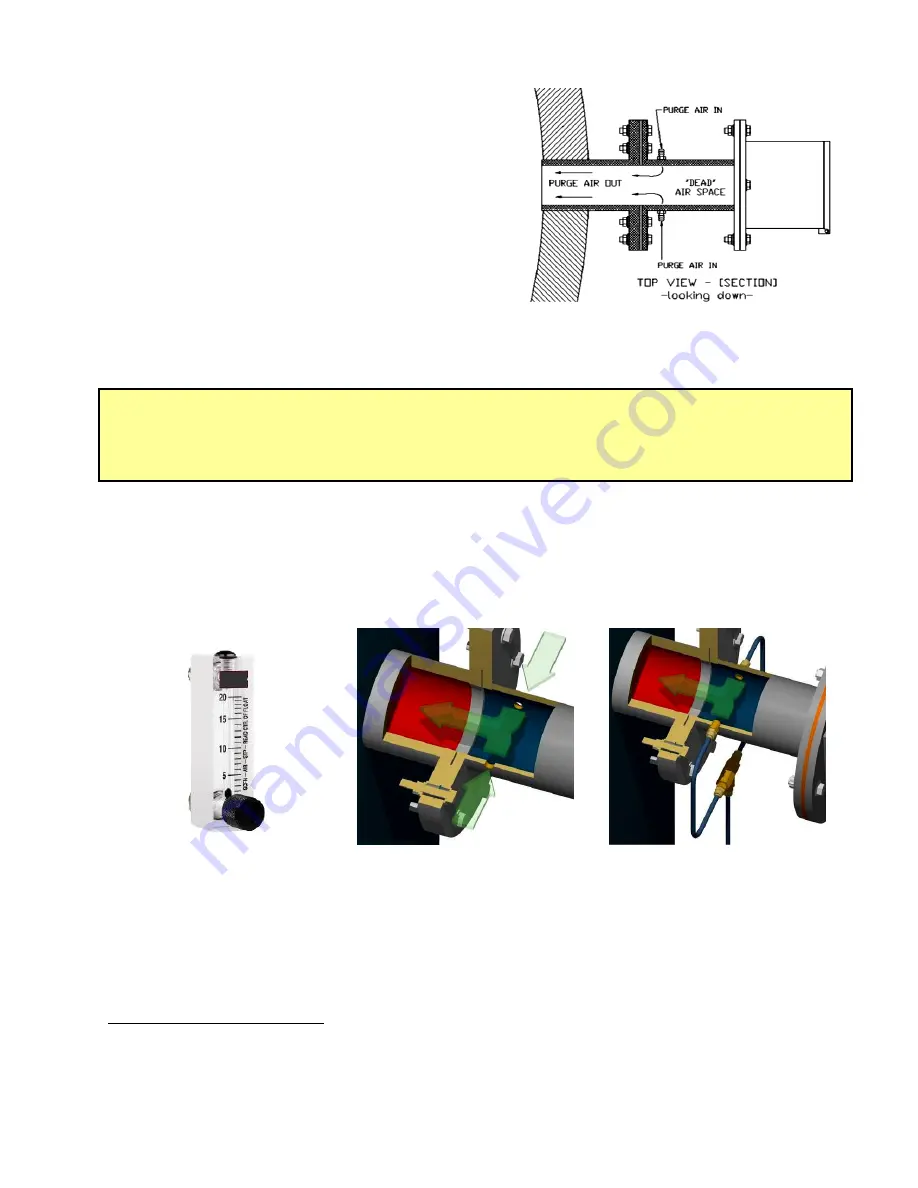

Active Purge

It is recommended the user apply instrument grade

1

compressed air (nitrogen, or other available clean gas) to

the purge fittings. This purge air should be controlled through a rotameter. (See Figure 3.7) The nominal

volume to start with is 1 CFM per fitting. There are two fittings per spool piece and four fittings per OFS

system. So: 4 CFM supplied altogether; with 2 CFM going to the Transmitter side, and 2 CFM going to the

Receiver side.

The flange adapters each have two purge holes threaded for 1/8” NPT and are supplied with fittings sized for

¼” tubing. These must be oriented so that the two holes are at right angles (90°) to the direction of the flow.

This is very important:

the introduction of purge air flow aligned along the axis of stack flow will result in false

velocity reports

.

1

According to ISO 8573.1:

ISO Class 1-6-1 Industrial Grade Air: Efficient removal of solid particulates and oil. ISO Class 6 PDP or a 50%

(or less) Rh will be maintained.

Figure 3.6 Purge Air Detail

Figure 3.7 Rotameter

(flow meter)

Figure 3.8 "Natural" Air Purge

Figure 3.9 Compressed Air Purge