10

RESET

RE

SET

M2

1

2

3

4

THERM-O-DISC

1

2

RESET

RE

SET

M2

1

2

3

4

THERM-O-DISC

1

2

RESET

RE

SET

M2

1

2

3

4

THERM-O-DISC

1

2

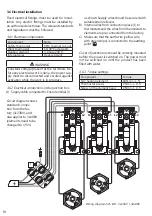

L1

L2

L3

L1

L1

L2

L2

L3

L3

Wiring diagram 3x5 kW - 3x230V / 3x400V

3.6.3 Torque settings

!

WARNING

Constant voltage present at the terminals. Be-

fore any electrical work is done, the power sup-

ply must be disconnected and secured against

activation while the work is in progress.

Component

Torque

5/4” heating element

60 Nm (+/- 5)

Thermostat screws

2 Nm (+/- 0.1)

Screw on the element head

2 Nm (+/- 0.1)

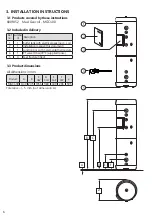

3.6 Electrical installation

3.6.1 Electrical components

Component

Note

Safety thermostat

98°C thermal cut-out

Work thermostat

60-90°C adjustable

Heating element

3-phase 230 V

Internal wires

Heat-resistant

Fixed electrical fittings must be used for instal-

lation. Any electric fittings must be installed by

an authorised electrician. The relevant standards

and regulations must be followed.

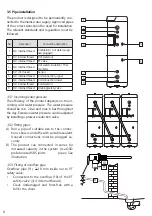

3.6.2 Electrical connections in the junction box

A) Supply cable connected to Ensto terminal (1)

1

Circuit diagram shows

standard connec-

tion from the fac-

tory (3x230V), and

also applies to 3x400V

(elements need to be

changed to 415V).

as shown. Supply wires should be secured with

suitable strain relievers.

B) Internal wires from connection piece (1) to

thermostats and the wires from thermostats to

elements are pre-connected from the factory.

C) Make sure that the earth wire (yellow wire

with green stripe) is connected to the earthing

point

Cover of junction box should be correctly mounted

before the power is switched on. The power must

not be switched on until the product has been

filled with water.