4

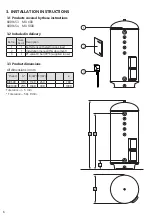

1.3 Safety instructions for installers

!

WARNING

The overflow from the TP safety valve must NOT be sealed or plugged. Safety valve sup-

plied with the product

!

Any overflow pipe from the safety valve MUST be > 18 mm inside, clear, undamaged and

frost-free with a fall to the drain.

!

The relevant regulations and standards, and this installation manual, must be followed.

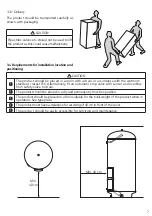

1.2 Safety instructions for users

!

WARNING

The overflow from the TP safety valve must NOT be sealed or plugged.

The product must NOT be modified or changed from its original state.

Children must NOT play with the product or go near it without supervision.

!

Maintenance/settings should only be carried out by persons over 18 years of age, with sufficient

understanding

!

CAUTION

The product must not be exposed to frost, over-pressure, over-voltage or chlorine treatment.

See warranty provisions.

Maintenance/settings should not be carried out by persons of diminished physical or mental

capacity, unless they have been instructed in the correct use by someone responsible for their

safety.

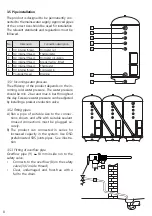

!

CAUTION

!

The product should be placed in a room with a drain, in accordance with the wetroom

standard / latest TEK. Alternatively, fit an automatic stop valve with sensor and overflow

from safety valve to drain.

Liability for consequential damage will only apply if this is followed.

!

The product should be properly aligned vertically and horizontally, on a floor suitable for the

total weight of the product when in operation. See type plate.

!

The product must have a clearance for servicing of 40 cm in front of the cover.