7

3.4 Requirements for installation location and positioning

!

CAUTION

!

The product should be fitted in accordance with Part G3 of building regulations.

Liability for consequential damage will only apply if this is followed.

!

The safety valve supplied must be mounted on the cold water supply to the boiler. See

section 3.5.2.

!

The product should be placed in a dry and permanently frost-free position.

!

The product should be mounted on a wall suitable for the total weight of the product in operation.

!

If the product is fitted horizontally, the pipe connectors must point straight up.

It is

recommended that the product be screwed tight to the wall or a suitable surface regard-

less of the method chosen; use the screw holes (D).

If the product is fitted vertically, the electric box must face upwards. See page 8.

!

The product should be mounted to allow access to the junction box when needed. Mains cable

can be placed in the finished channels in the back of the product. Mains cable for wall socket

should be laid where it is not exposed to harmful contact.

!

The product should be easily accessible in the home for servicing and maintenance.

IMPORTANT: If the insulation is not correctly and

completely fitted, the product will not achieve

the specified ErP energy rating. The energy con-

sumption of the product could increase.

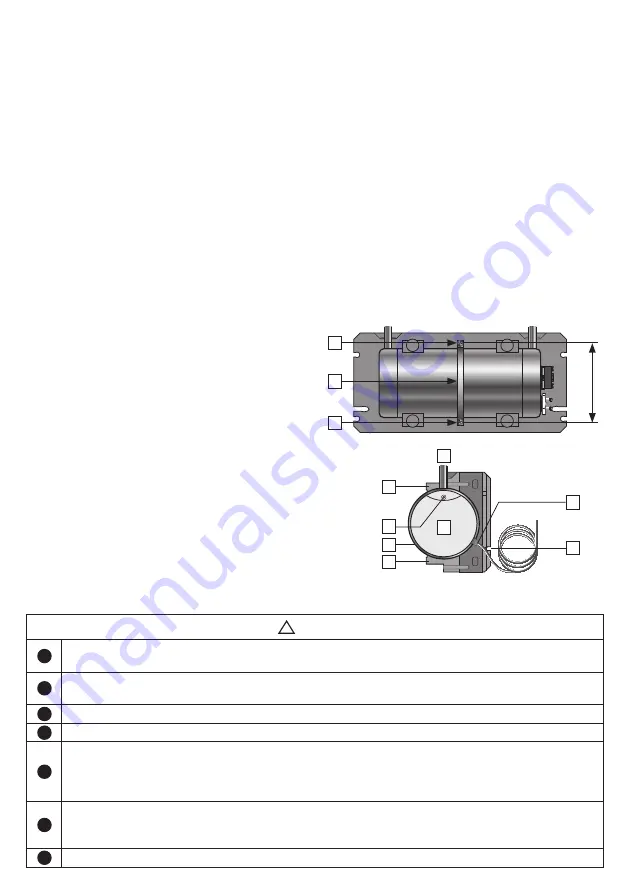

3.3.3 Wall fitting

The product is designed for to be mounted on a

wall When the insulation cap is removed, there is

easy access to the screw holes (D).

The Nano is attached to the wall with the mount-

ing band supplied (V); see illustration. The metal

band is bent/placed around the middle of the

tank and fixed to the wall through the holes in the

insulation, using the screws/washers supplied.

Ensure that the connectors do not press on the

insulation parts. Use bits of the torx type (T25).

Tighten the screws until the insulation around the

screw holes deforms.

3.3.4 Reversing the inner tank

For horizontal mounting, the inner tank can be

reversed if it is desirable to swap the CW and HW

connections for ease of fitting. Important: This

can only be done when the electricity is not con-

nected.

1. Remove the insulation (see 3.3.2).

2. Remove the electrical cover by loosening

the nut (E). Then unscrew the strain reliever

for the mains cable (F) and remove the elec-

trical cover.

3. The electrical cover (I) may be modified by

opening the alternative fixing for the strain

reliever (K). Material in the recess should be

E

H

H

K

F

J

G

I

removed and the strain reliever with cable

fitted into the new channel.

4. Remove the mounting band (V). Pull the

tank out so the connections clear the at-

tachment points (H). Turn the tank 180° and

push it back into the attachment points. Fit

the mounting band.

5. Ensure that connections and the coloured

rings (red/blue) indicating HW and CW are

positioned correctly in the slots.

6. Fit the electrical cover with the nut (E), then

fit the insulation cap. The end-parts of the

insulation must now swap places.

7. The product has built-in channels in the

back (J) for simple and tidy routing of the

mains cable at the back of the product.

D

V

D

C-C

174 mm