September, 2014

Page 4 of 8

should be applied over the entire surface or

along the rim.

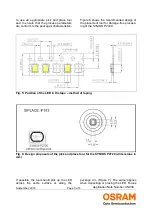

Fig. 7: Recommended pick-up area for

SYNIOS P2720

Since the SYNIOS P2720 is generally

supplied in tape with dry pack, it should be

factory-sealed when stored.

The hermetic pack should only be opened

for immediate mounting and processing,

after which the remaining LEDs should be

repacked according to the moisture level in

the datasheet (q.v. JEDEC J-STD-033B.1 -

Moisture Sensitivity Levels).

Storage

PCBs or assemblies containing LEDs should

not be stacked such that force is applied to

the LED, or should not be handled directly at

the LED.

Fig. 8: Incorrect storage of LEDs

Generally, all LED assemblies should be

allowed to return to room temperature after

soldering, before subsequent handling, or

the next process step.

Fig. 9: Correct storage of assemblies with

LEDs

Cleaning

From today's perspective any direct

mechanical or chemical cleaning of the

SYNIOS P2720 is forbidden.

Isopropyl alcohol (IPA) can be used if

cleaning is mandatory. Other substances or

especially ultrasonic cleaning of SYNIOS

P2720 are generally not recommended.

For dusty LEDs, a simple cleaning by means

of purified compressed air (e.g. central

supply or spray can) is recommended here.

In any case, all materials and methods

should be tested beforehand, particularly as

to whether or not damage is associated with

the component.

Notes concerning cleaning can be also

found in the corresponding data sheets.

Processing

Generally, the SYNIOS P2720 product

family is compatible with existing industrial

SMT processing methods, so that current

populating techniques can be used for the

mounting process.

The individual soldering conditions for each

LED type according to JEDEC can be found

in the respective data sheet.

A standard reflow soldering process with

forced convection under standard N

2

atmosphere is recommended for mounting

the component, in which a typical lead-free

Application Note Number: AN038