―E12―

6. CONNECTION PROCEDURE (continued)

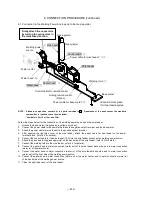

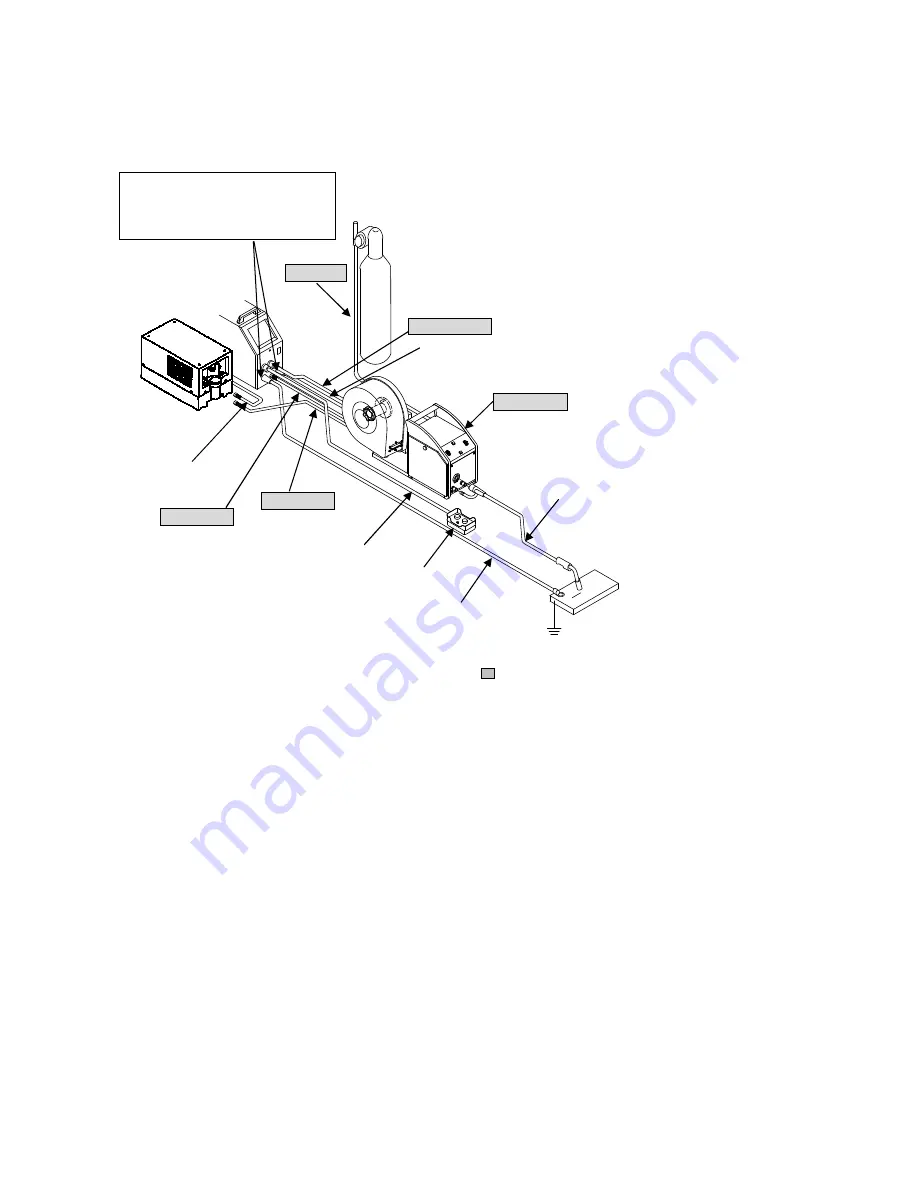

6.1 Connection to the Welding Power Source and to the Gas regulator

NOTE:

Standard composition consists of the parts indicated in

. Preparation of the parts except the standard

composition is required to use the wire feeder.

*Available in 5m, 10m, 15m, and 20m.

Follow the steps below for the connection of the welding power source and the wire feeder.

1. Ground the base metal (if required by local laws or codes).

2. Connect the power cable for base metal between the negative output terminal and the base metal.

3. Attach the power cable for wire feeder to the positive output terminal.

4. After opening the right-side cover of the wire feeder, attach the power cable for wire feeder to the power

terminal block. (refer 6.2 for details)

5. Connect the control cable for the wire feeder (10P) into the wire feeder socket on the welding power source.

6. Attach the gas hose to the gas supply inlet on the back side of the wire feeder. (refer 6.4 for details)

7. Connect the welding torch to the wire feeder. (refer 6.3 for details)

8. Connect the water hose to water connection (water out) of the wire feeder back side, and to water connection

(water in) of the water cooler.

9. Connect the water hose to water connection (water in) of the wire feeder back side, and to water connection

(water out) of the front side of the welding power source.

10. Connect the water hose to water connection (water out) of the water cooler, and to water connection (water in)

of the back side of the welding power source.

11. Close the right-side cover of the wire feeder.

Firmly attach the connectors

by turning the connectors in

the clockwise direction.

Water hose*

⑨

Water hose*

⑧

⑥

Gas hose*

Gas cylinder

Gas regulator

Control cable*

⑤

Wire feeder

Power cable for wire feeder*

③④

Power cable for base metal*

②

Control cable for remote control

Analog remote control

(Option)

Welding power

source

Ground a work piece

if a local law requires.

Water cooler

Water hose*

⑩

Base metal

Welding torch

⑦