―E13―

6. CONNECTION PROCEDURE (continued)

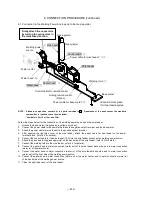

6.2 Connecting of the Power Cable for Wire Feeder

WARNING

∗

Touching the charging parts may cause in fatal electric shock and severe burns.

●

Do not touch the charging parts of the welding machine.

●

Have a qualified electric engineer ground the case of the welding power source and the base

metal or jig electrically connected in accordance with a local low.

●

Disconnect the wire feeder from the welding power source by turning off the line disconnect

switch in the power box to avoid an electric shock before the welding power source or base

metal and connecting the cables or hoses.

●

After connecting the cables, cover the power source with the cover or case.

●

When using the welding machine in such a humid environment as construction site, on the

steel plate, or on steel structure, install a leakage breaker.

CAUTION

●

Use the proper power cable that matches the welding current.

Applicable current (Rated current)

Cable thickness

200 A

38mm

2

or more

350 A*

60mm

2

or more

500 A

80mm

2

or more

* When performing pulse welding using the welding power source with 350 A welding current and

17m or more cable, use the thicker cable by one rank.

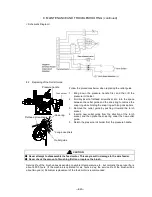

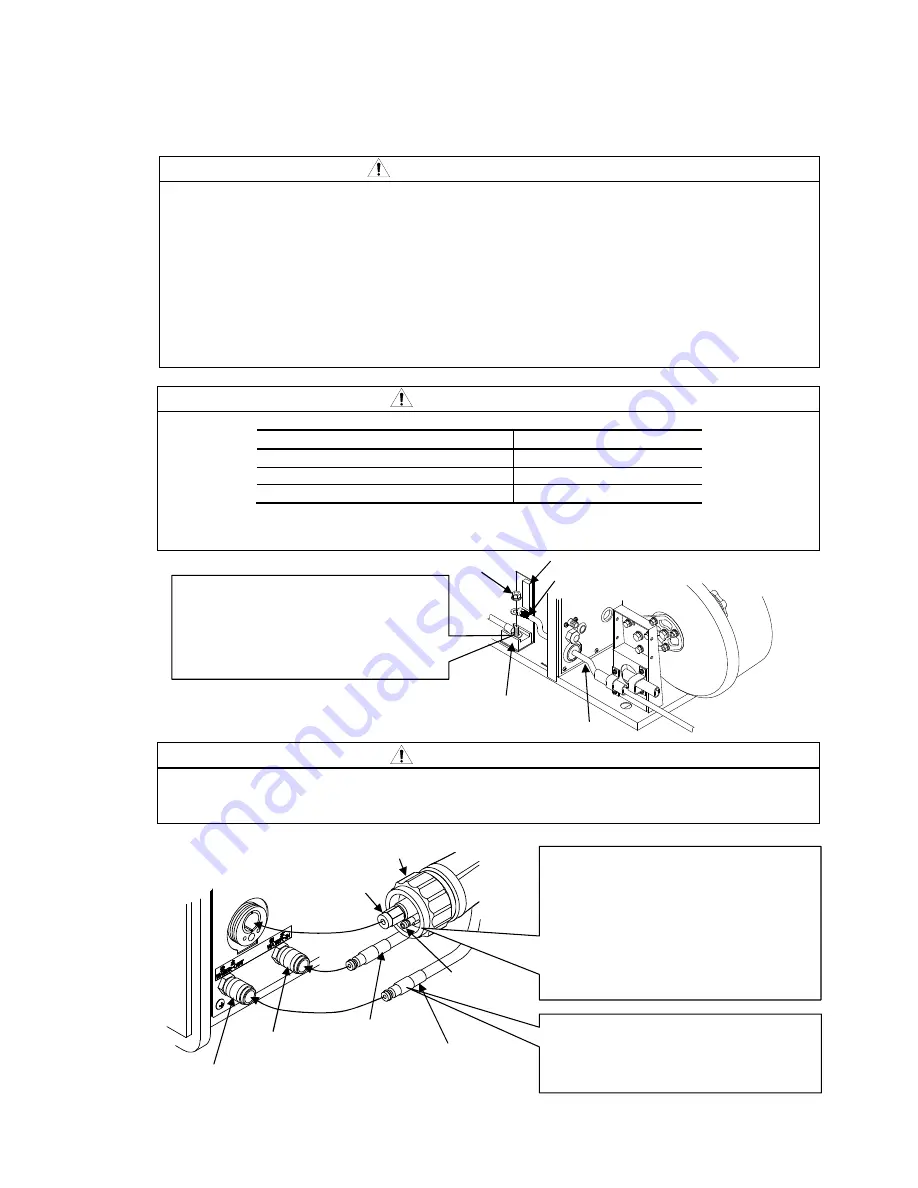

6.3 Connecting of the Welding Torch

CAUTION

●

Ensue that the torch connector is firmly attached. If the connector is not fully inserted, there

may be a risk of fire, burns, and product damage.

●

Water might leak when water out/in hose of the welding torch is not been properly inserted.

Please insert the water-in hose and the water-

out hose of the welding torch into the water

connection of the wire feeder with clicked

sound.

Welding torch

Adapter nut

Power supply metal fittings

Gas connection

metal

Water hose (blue)

Water hose (red)

Water connection

(Water in)

Water connection

(Water out)

Power cable for wire feeder

Insulating tape

M10 nut

Take care to attach the power cable

firmly to prevent the cable from touching

the frame and the terminal block*. Put

around the terminals of the cable with

insulating tape.

Power terminal block

Terminal block*

Before connecting a wire feeder to a welding

torch, make sure that the power supply metal

fittings and gas connection metal are inserted

into the welding torch until restricted and that

the adapter nut is properly inserted into the

welding torch. (Forcible insertion of the

adapter nut may cause in damage to the

threads of the metals.)