―E16―

7. WELDING PREPERATION (continued)

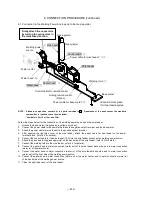

7.2 Mounting of the Feed Roll

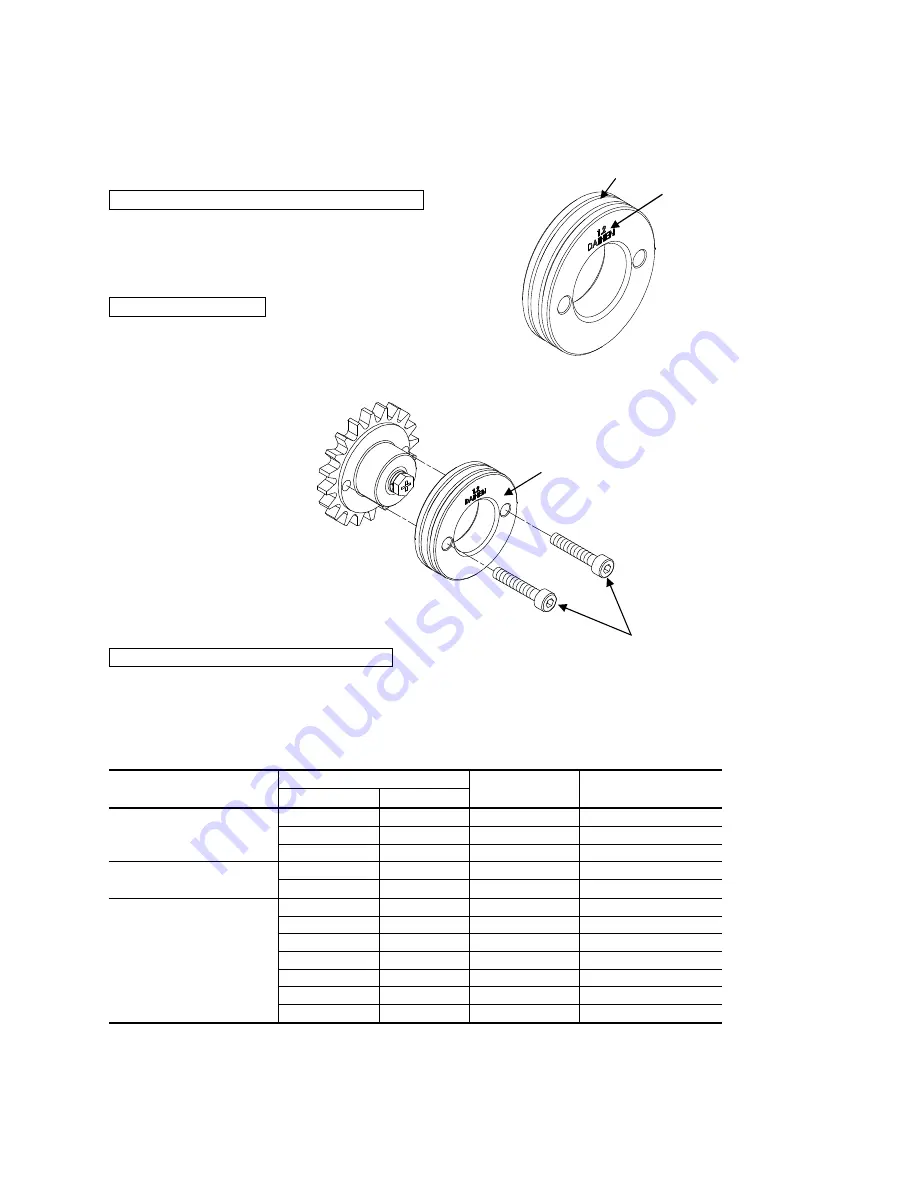

Confirming of the wire size marked on the feed roll

Use the proper feed roll for the wire size.

The feed roll of

φ

1.2 wire size is mounted on the CMAW-7401

wire feeder.

Replacing of the feed roll

1. Remove the hexagon socket cap screws fixing the feed

roll.

2. Bring down the pressure handle, and then lift the pressure roll holder.

3. Separate the feed roll from the wire feeder by pulling out the feed roll toward you.

4. Mount the feed roll, with the wire size marked on the wire feeder facing out.

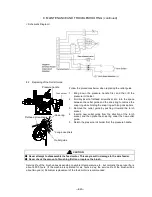

Adjusting of the wire pressure and straightner

•

Set to the proper wire pressure for the wire type by turning the pressure handle.

•

The numeral on the pressure scale set with the right pressure handle should be correspond to the one

set with the left pressure handle.

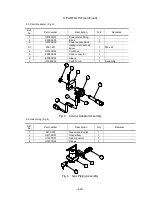

Recommended wire pressure adjustment

Wire diameter

Pressure

handle scale

Wire straightner

scale

(

φ

mm

)

(

inch

)

Hard aluminum

AL/MG (HARD)

1.6

1/16

2-3

2-3

1.2

3/64

1-2

3-4

1.0

0.035

1-2

4-5

Soft aluminum

AL/PURE (SOFT)

1.6

1/16

2-3

2-3

1.2

3/64

1-2

4-5

Mild steel

Stainless steel

Brazing

1.6

1/16

3-4

(2-3)

1.4

0.055

3-4

(3-4)

1.2

0.045

2-3

(3-4)

1.0

0.040

2-3

(4-5)

0.9

0.035

2-3

(4-5)

0.8

0.030

1-2

(4-5)

0.6

0.023

1-2

(4-5)

*Applicable wire diameter of brazing wire is

φ

0.8, 0.9, 1.0 and 1.2.

*Refer to section 8.3 for wire feeding of other than aluminum.

Groove for

φ

1.2 wire size

Wire size mark

Hexagon socket cap screws

Feed roll