Oven CR-5000G*

page 3

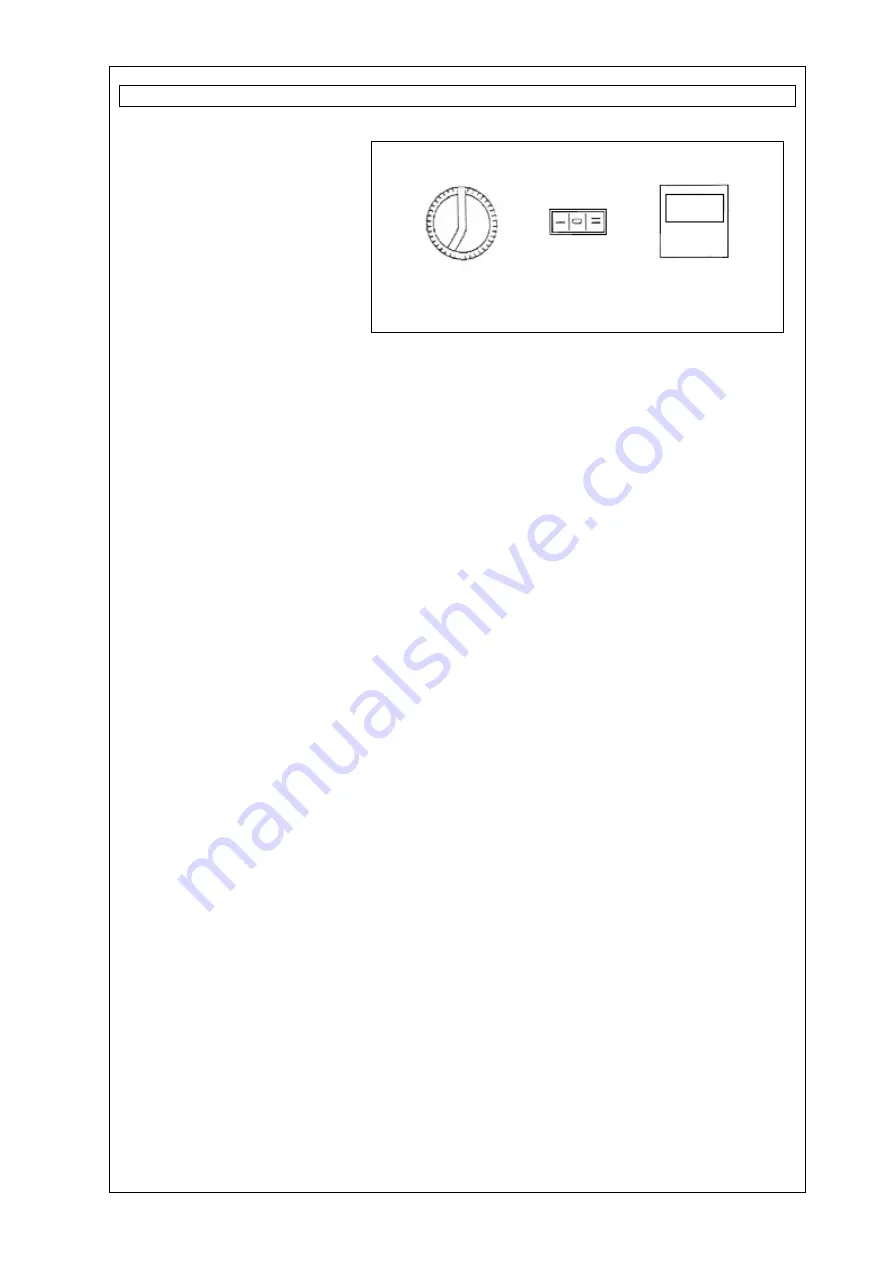

8. Operation:

8.1 Set the timer (3) on

desired time in min.

and tip the switch (2)

on the position I,

- or:

8.2 tip the switch on the

position II for manual

operation.

In both cases all LEDs and the display on K 48 are lighting up, as well as the three pilot

lamps, indicating the presence of three phases of the mains (in case of absence of one of

them, check the fuses and/or the main board).

8.3 Stopping the oven:

- set timer on "0",

- tip the switch on "0".

All lights and the displays go out.

WARNING: after having switched ON the oven, the temperature must increase at the rate of

3 to 4°C/minute. The indicator OUT (output) must li ght with no interruption up to approx.

140°C.

Periodical interruptions during this heating period indicate that the controller is out of order

and that the internal parameters have to be readjusted.

9. Cleaning and maintenance:

Warning: cleaning can only be performed when the unit is cold and disconnected

from the electrical network.

All parts of stainless steel shall be cleaned with a cloth soaked in the detergent solution and

than wiped up with a dry cloth.

Personnel operating the units have to be well familiar with the present instructions. In

addition to their ability to perform their basic job. They shall also be familiar with functioning

of the unit, its operating and cleaning.

10. Additional information:

The maximum allowable temperature is 300°C. The inc orporated security thermal fuse is set

on 320°C. In case of sensor's failure and of trespa ssing this temperature, this fuse switches

off the heating power and displays.

In this case, the general electrical supply has to be disconnected. After the oven has been

cooled down and the defect repaired, the rectangular plate under the left rear corner of the

oven has to be taken off, giving access to the three-phase connector, actuated by the

thermal fuse. It has to be reactivated by pushing the corresponding button.

In case of any other malfunction, the intervention of authorized and competent staff

members or service men only is allowed.

WARNING: THE STORAGE TEMPERATURE HAS TO BE KEPT BETWEEN 0° AND +50°C.

Timer Main switch

K 48

⊗

⊗

⊗

Pilot lamps indicating the presence of three phases