P 32

OTS-3000 User Manual – FAQ

F A Q

2. Is your OTS-3000 for quality finishing ?

Ans:

Yes , also our OTS-3000 equipment can do the final layer finishing .

3. Do I need to pre paint the metals with anticorrosion or ?

Ans:

Yes , you can do it, if your metal need it .

4. How long is needing to dry liquid paint ?

Ans:

It is depend on your paints , Please ask your paints provider for this information.

5. What type of surface preparation do I do (or not do)?

Ans:

a. Removal of tape, tags, plates and other debris.

b. Surface sanding to assure good adhesion of the new paint .

c. Surfaces are wiped down with solvents and / or degreasers.

d. Masking of parts not to be painted.

e. Priming (anticorrosion) when and as required

f. Replace removed parts, unmask and cleanup.

6. Do you have different products or regulations for paints with high or

low resistivity/conductivity?

Ans:

Our OTS-3000 electrostatic power supply and gun are full range ability,If the high and low

resistivity/conductivity paints are used with our gun , you have to adjust the electrostatic

power meter until you can smooth spray paint. so it is not problem with our equipment

.however the best resistance value of paint is between 20 and 30MΩ.

7. Do you have electrostatic equipment for water-based paints? When you talk about

waterborne is the same as water-based paints? If so, is it the same equipment?

Ans:

Our OTS-3000 electrostatic power supply and gun are full range ability, So our equipment

can use water-based paints. you can refer our user manual for more detail .

Waterborne= water-baesed ,

It is same equipment , this function is one of our best advantage .if you have our

OTS-3000 ,you can use solvent and waterbase paints with no limited. In addition , you just

need to pay one equipment fee only.

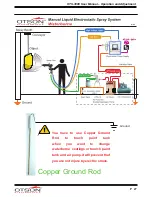

8. Which is the method that you suggest to ground the equipment? And the sprayer (operator)?

How is it done?

Ans:

Using ground wire. Please refer our user manual Page .