Service work

490E75=0_C

14 | Ottobock

• Liquid thread lock, "medium" and "strong"

• Side-cutting pliers

• Drill; twist drill Ø 5.2 mm

4.5

Basic work

4.5.1 Jacking up the wheelchair

CAUTION

Improper lifting

Crushing, pinching, blows due to failure to observe safety instructions

f

The wheelchair is heavy. Ensure ergonomically correct lifting. Use sufficiently large hoisting devices or perform

this work with a helper.

f

If it is necessary to work underneath raised parts or equipment, make sure these are secured by suitable means

so that they cannot come loose, shift, or fall down.

f

Always use an assembly stand with a load capacity that at least corresponds to the overall weight of the

wheelchair.

f

When using lifting platforms or an assembly stand, ensure that the power wheelchair is centred on the sup-

porting surface and that no parts protrude into the danger zone.

f

Always secure a jacked up wheelchair against tipping over with the active support of a helper when the seat is

folded up. Always fold down the seat before jacking the wheelchair up or down.

NOTICE

Incorrect lifting

Damage to the product, tearing off of side panels due to user error

f

Do not use the side panels to lift the wheelchair.

Jacking up is required for work on the following components:

• Drive wheels, drive wheel swing arms and suspension

• Caster wheels, caster wheel swing arms and suspension / rigid elements

• Drive motors

Jacking up with an assembly stand

1) Activate (lock) the brakes on both drive motors.

2) Tip the wheelchair with the active support of a helper.

INFORMATION: A wheelchair with mid-wheel drive MWD can be tilted sideways to jack it up. Grasp the

seat frame for tipping. Do not use the side panels to lift the wheelchair. Do not pull or push on the side

panels or arm supports!

3) GD?@<I<NN@H=GTNO<I?JANPAu>D@IOGJ<?><K<>DOT<I?NDU@PI?@MOC@HJ=DGDOT=<N@JAOC@RC@@G>C<DMNJDODN

centred.

4) Carefully lower the wheelchair, centring it on the assembly stand. The mobility base has to lie evenly on the sup-

porting surface of the assembly stand.

5) Check that the wheelchair is securely positioned on the assembly stand.

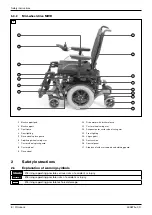

Summary of Contents for 490E75 Series

Page 1: ...490E75 0_C Service manual...

Page 38: ...Service work 490E75 0_C 38 Ottobock 57 58 59 60 61 62 63...

Page 41: ...Service work 490E75 0_C Ottobock 41 70 71 72 73 74 tt 75 76...

Page 55: ...Service work 490E75 0_C Ottobock 55 103 104 105 106 107 108 109 110...

Page 108: ...Service work 490E75 0_C 108 Ottobock 227 228 229 t 230 231 232...

Page 112: ...Service work 490E75 0_C 112 Ottobock 237 238 239 240 241...

Page 143: ...R Net wheelchair control 490E75 0_C Ottobock 143 Seat module pin assignment 287...

Page 161: ...490E75 0_C Ottobock 161...

Page 162: ...490E75 0_C 162 Ottobock...