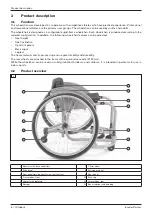

Use

Invader Pointer

Ottobock | 11

CAUTION

Improper use of self-locking nuts

Tipping, falling over of the user due to screw connections coming loose

f

Always replace self-locking nuts with new self-locking nuts after disassembly�

Adjustments to match the concrete physical and mental condition of the user should always be made in the user's

presence�

All parts of the product should be cleaned thoroughly before adjustments are made�

Please note the following instructions when carrying out any adjustment:

• Adjust the wheelchair such that the seat bottom is horizontal or tilted to the rear�

• Adjust the centre of gravity such that the user can push the rear wheels as effectively as possible�

• Adjust the height of the side panels such that their upper edge is as parallel to the rear wheels as possible�

• Adjust the wheelchair such that the front frame tubes do not protrude beyond the bumper�

Concrete settings (e�g� seat and back upholstery etc�) are described in the following sections with the respective

components�

The tools required for adjustments and maintenance tasks as well as the torque values for screw connections are

listed in the section "Technical data" (see Seite 29 ff�)�

7.3 Seat

WARNING

Seat cushion and back pad may ignite

Burns due to user error

f

The seat and backrest upholstery as well as padding fulfil the requirements for flame resistance according to

ISO 8191-2 and DIN EN 1021-2� However, they may still ignite if fire is handled improperly or negligently�

f

Keep away from all ignition sources, especially lit cigarettes�

NOTICE

Wear of the seat and back upholstery

Loss of functionality due to unallowable continued use

f

Replace the seat and back upholstery promptly in case of damage�

The seat cushion and the seat upholstery ensure pressure relief during use of the wheelchair� They can be adjusted

according to the needs of the user�

7.3.1 Optional: removing and fastening the seat cushion

The seat cushion can be removed for cleaning�

1) Remove the seat cushion from the seat pad�

2) After cleaning (see Seite 23): Fit the seat cushion on the seat pad� The seat cushion is secured against

sliding by being pressed on to the hook-and-loop fastener�

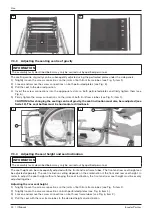

7.3.2 Adjusting the seat upholstery

The seat upholstery is attached to the frame tubes by 2 upholstery bars and is tensioned on one side with a hook-

and-loop closure on the underside�

1) Optional: Remove the seat cushion from the seat pad�

2) Loosen the screw connections on the upholstery bars (see Fig� 3, item 1)�

INFORMATION: Loosen the screw connections only until the seat upholstery underneath can be moved.

3) Open the hook-and-loop closure along the upholstery bar (see Fig� 4)�

4) Adjust the tension of the seat pad to the weight and anatomical condition of the user and securely fasten the

hook-and-loop closure along the upholstery bar�

INFORMATION: The hook-and-loop closure must completely overlap itself.

5) Firmly tighten the screw connections on the upholstery bars (see Fig� 3, item 1)�

6) Optional: Attach the seat cushion to the seat pad�