NOTICE

Warning regarding possible technical damage.

3.2 General safety instructions

WARNING

Lack of instruction

Tipping over, falling of the user due to lack of knowledge

►

Instruct the user or the attendant in the proper use of the product when handing it over.

CAUTION

Use of unsuitable tools

Pinching, crushing or damaging the product due to use of unsuitable tools

►

When completing the tasks, only use tools that are suitable for the conditions at the place of work and for

which safety and the protection of health are assured with proper use.

►

Observe the specifications in the section "Required Tools".

NOTICE

Tipping or falling of the product

Damage to product due to lack of attachment

►

When you work on the product, secure it so that it cannot tip over or fall over.

►

Use a clamping fixture to secure the product whenever you work on it at a workbench.

NOTICE

Use of unsuitable packaging

Damage to the product caused by transportation using incorrect packaging

►

Use only the original packaging for delivery of the product.

3.3 Safety Instructions for Assembly

WARNING

Changed diameter/installation position of the wheels

Tipping, falling over of the user due to blocked wheels

►

Modification of the size and position of the front wheels and of the drive wheel size can lead to wobbling of the

front wheels at higher speeds. If changes are required, verify the horizontal alignment of the wheelchair frame

(see the section "Adjusting the drive wheels", "Adjusting the caster wheels").

WARNING

Improper assembly of removable wheels

Tipping, falling over of the user due to wheels coming off

►

After each assembly, verify the proper fit of the removable wheels. The quick-release axles must be firmly

locked in the wheel attachment.

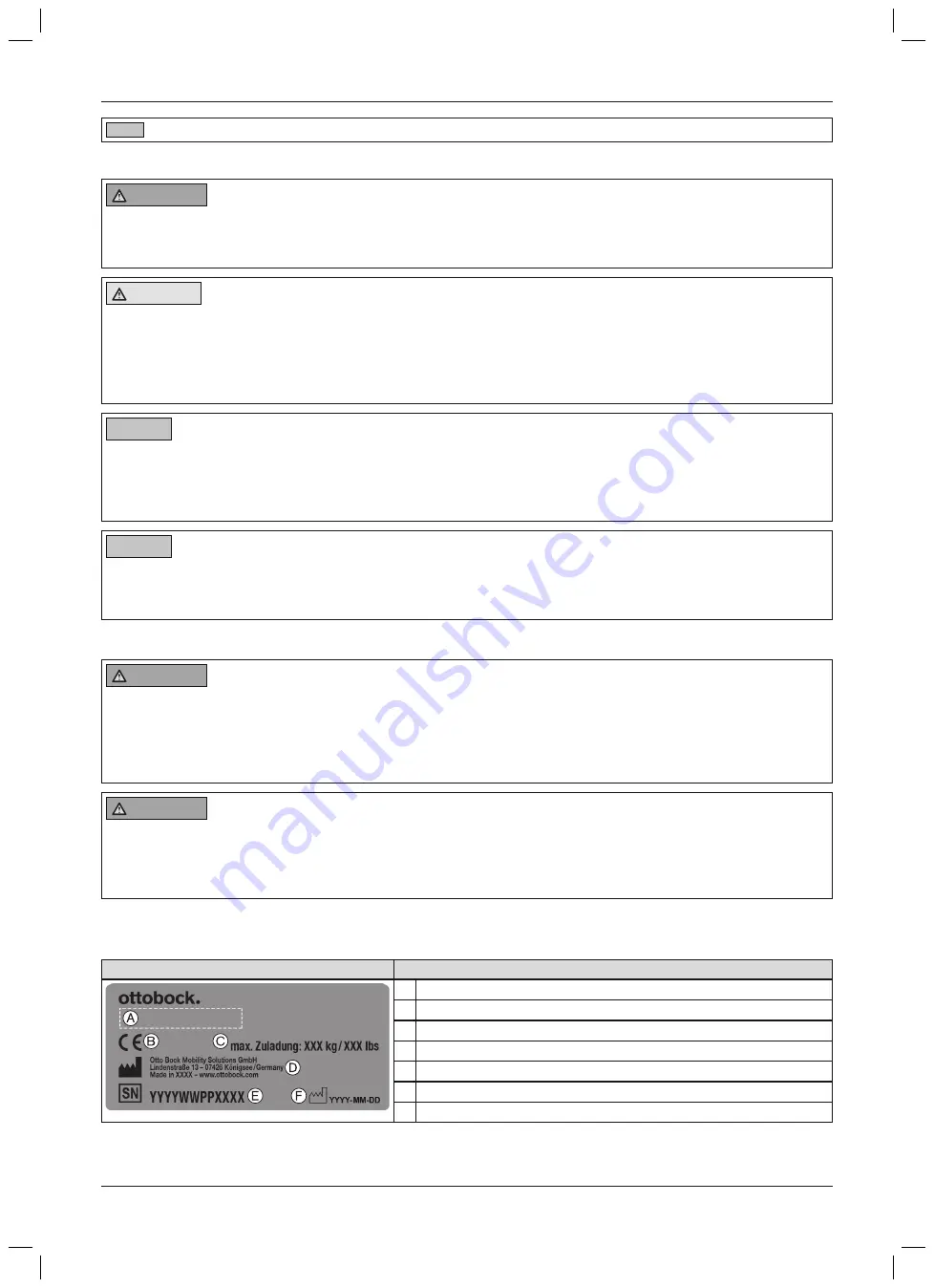

3.4 Nameplate

The nameplates are found on the crossbrace.

Label

Meaning

A

Manufacturer’s product name

B

CE marking

C

Maximum load (see section “Technical data”)

D

Manufacturer information/address

E

Serial number

1)

F

Manufacturing date

2)

G

Manufacturer’s article number for the product variant

6

Safety

Start M2S, Start M2