→

Once changed, the left and right caster wheels must have the same vertical position in the caster fork.

→

Once the front seat height has been adjusted, the caster journal angle must be checked and if necessary read

justed.

12

13

6.4 Adjusting the brakes

6.4.1 Adjusting the wheel locks

WARNING

Failure to verify brake functionality

Accident, user falls due to incorrect adjustment and improperly inflated tyres

►

Check the correct spacing between the wheel lock bolt and tyre (see the following section for details).

►

Check the correct position of the wheel lock bolt relative to the tyre. During braking, the wheel lock bolt has to

cover at least half the tyre width.

►

Always carry out adjustments to the wheel lock on both sides.

►

Ensure that the user can operate the wheel lock without great effort. The force required to do so must not

exceed 60 N.

►

Check the tyre pressure of the drive wheels. Note the information in the section “Technical data” or on the tyre

sidewall.

►

Only use original drive wheels with a verified maximum radial out-of-round of

1 mm

.

This adjustment must be made after the drive wheel has been repositioned or during fine adjustment.

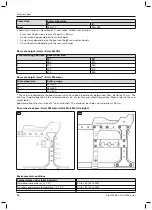

1) Loosen the Allen head screws on the clamp bracket (see fig. 14).

2) The knee lever wheel lock is continuously slidable and adjustable. When the wheel lock is disengaged, the gap

between the tyre and wheel lock bolt must not exceed

5 mm

(see fig. 15).

→

The distance between the wheel lock bolt and the drive wheel must be

1–5 mm

in the unbraked condition.

→

It must be possible to operate the brake evenly and easily on both sides.

→

The wheel lock bolt must lock the drive wheel securely when stationary.

3) Tighten the Allen head screws to

16 Nm

.

→

After adjustment, the left and right knee lever wheel locks must both have the same braking force.

14

15

14

Settings

Start M4 XXL, Start M6 Junior