Last Update: 2011-June INSTRUCTION MANUAL FOR THERMOSYPHONIC SYSTEMS

31/35

©TANSUG MAKİNA LTD. 2008

CHAPTER II

INSTRUCTIONS FOR THE USER

WARNING

: Make sure that all installation is carried out by your authorized installer. Check all

valves are properly working and the system is completely filled with water and antifreeze fluid.

In case of failure, read the instructions at the troubleshooting section. Always call your

authorized service store before taking any action.

12. SAFETY & SECURITY COMPONENTS

Your system has two circuits, each secured by a number of safety and security components.

The system comes equipped with safety components for the primary circuit. All safety

components required for the secondary circuit must also installed by your authorized installer.

12.1 Primary Circuit (Closed Loop Line):

•

Expansion tank:

preset 1,5 bar, working pressure 4 bar

•

Pressure relief valve:

5 bar

•

Air vent

160° C

12.2 Secondary Circuit (Cold Water Line):

•

Pressure reducer :

preset to 3 bars

•

Non-return valve

•

Pressure relief valve

5 bars

•

Control Valve

13. MAINTENANCE

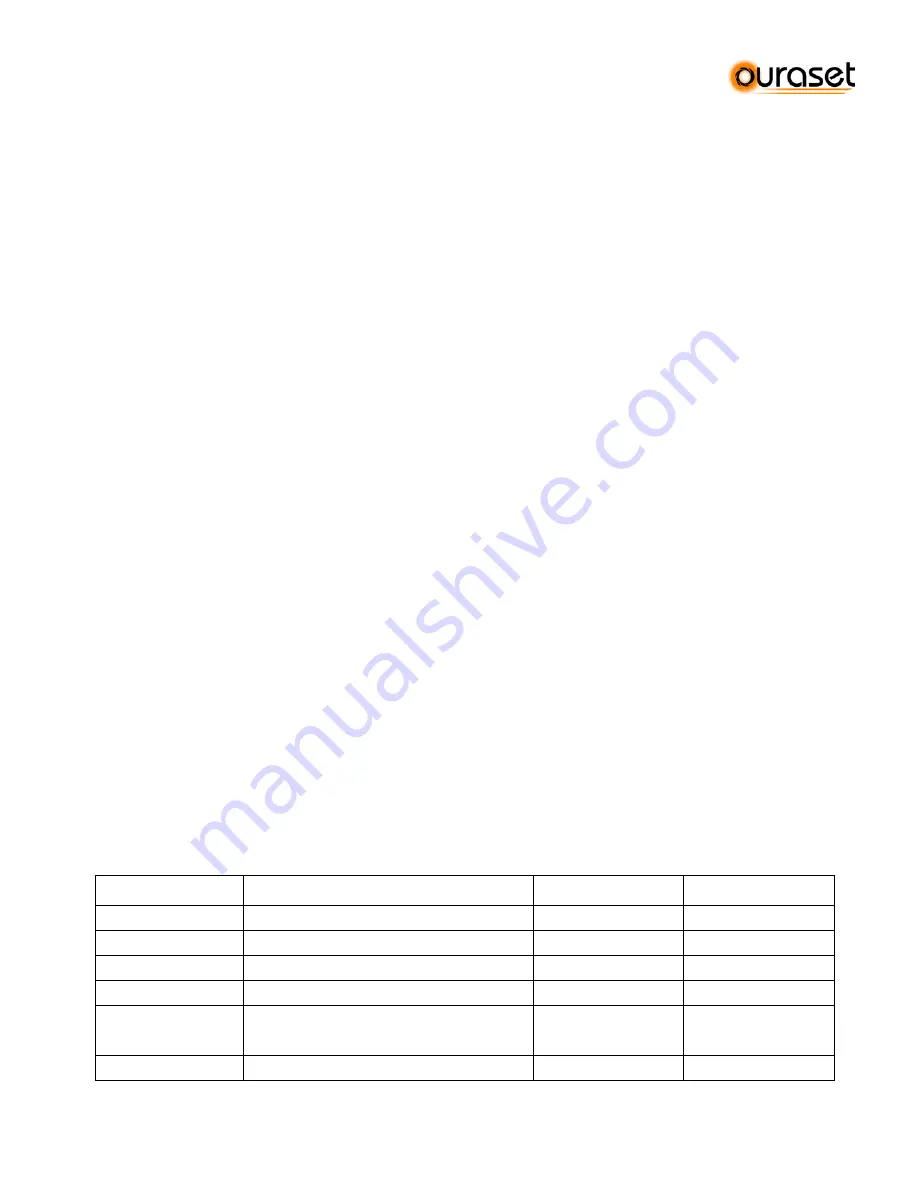

The following table lists the key components of your system that require regular inspection

and maintenance.

INSPECTION

Correct Status

Period of Control Average Life

Mg Anode

Must be complete

Annually

2 years

Antifreeze Fluid

Must be full

Annually

1 year

Pipe Insulation

Must be intact and solid

Annually

3 years

Fittings Accessories

Must function properly & not leak

Annually

2 - 5 years

Panels

(Closed Loop)

Inside panel must remain completely water and

weather proof

Every 2 years

12-20 years

Boiler –

closed circuit

No leakage and corrosion should occur in the tank

Annually

8-10

years