Page | 12

www.outdoorrooms.com

CF-1242 AU Rev-E 8/24/15

D. LP Gas Suppl y

•

The LP gas supply used with LP models must be constructed

and marked in accordance with the specifications for LP gas.

•

Cylinders must be stored outdoors in a well-ventilated area out

of the reach of children. Disconnected cylinders must have

threaded valve plugs tightly installed and must not be stored

in a building, garage or any other enclosed area.

•

Storage of this appliance indoors is permissible only

if it has been disconnected from its fuel supply.

•

The LP gas supply system must be arranged for

vapor withdrawal.

•

The specific size and capacity of the cylinder(s) to

be used: hard plumbed to propane tank.

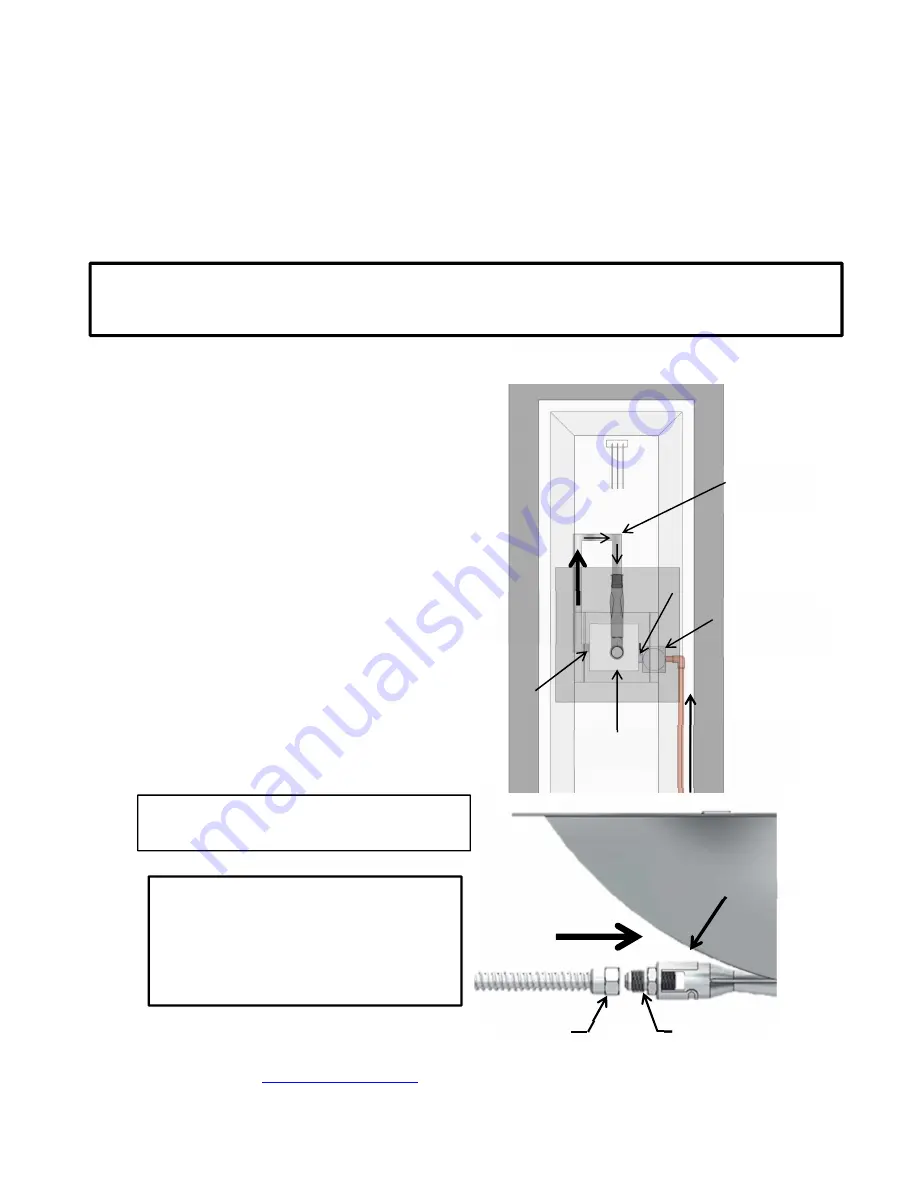

Gas Setup for Liquid Propane

1.

With burner in place in Outdoor

GreatRoom Company fire pit table or other

installation location and proper sized

injector inserted in burner neck (see chart

on p.4 for injector sizing),

2.

Incoming propane should be hard-plumbed

to the input of the gas control valve with an

approved regulator for propane. Tighten

securely using two wrenches.

3.

Locate the gas line (not supplied) and

tighten securely to output valve fitting

following the method described in step 2.

4.

Using two wrenches, securely tighten the

flare nut on the free end of the metal flex

hose to the injector on the burner.

5.

For liquid propane installations, the air

shutter must be left open as shown at

lower right to prevent soot buildup.

To

adjust air shutter, loosen the small securing

screw and rotate air shutter to allow more

or less airflow.

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION SERVICES, OR MAINTENANCE CAN CAUSE INJURY OR

PROPERTY DAMAGE. REFER TO AND UNDERSTAND THIS MANUAL. FOR ASSISTANCE OR ADDITIONAL INFORMATION

CONSULT A QUALIFIED INSTALLER, SERVICE AGENCY, LICENSED TECHNICIAN OR THE GAS SUPPLIER.

Flare Nut

Injector

Venturi/Air shutter

CHECK ENTIRE SYSTEM FOR LEAKS BEFORE

OPERATING. IF AN INSTALLER IS

CONVERTING THE UNIT FROM NATURAL

GAS TO LP, RE-CHECK ALL CONNECTIONS

FOR LEAKS BEFORE USE.

Gas from

control valve

Burner shape may differ from your model

Overhead view of burner and valve system

Incoming gas

supply (hard

piped)

Propane regulator

(locate under drip

guard)

Gas control

valve

Corrugated

metal flex-line

Gas flow from

valve to burner

Gas out

Gas in

AN APPROVED REGULATOR MUST BE FITTED BY

THE INSTALLING PLUMBER