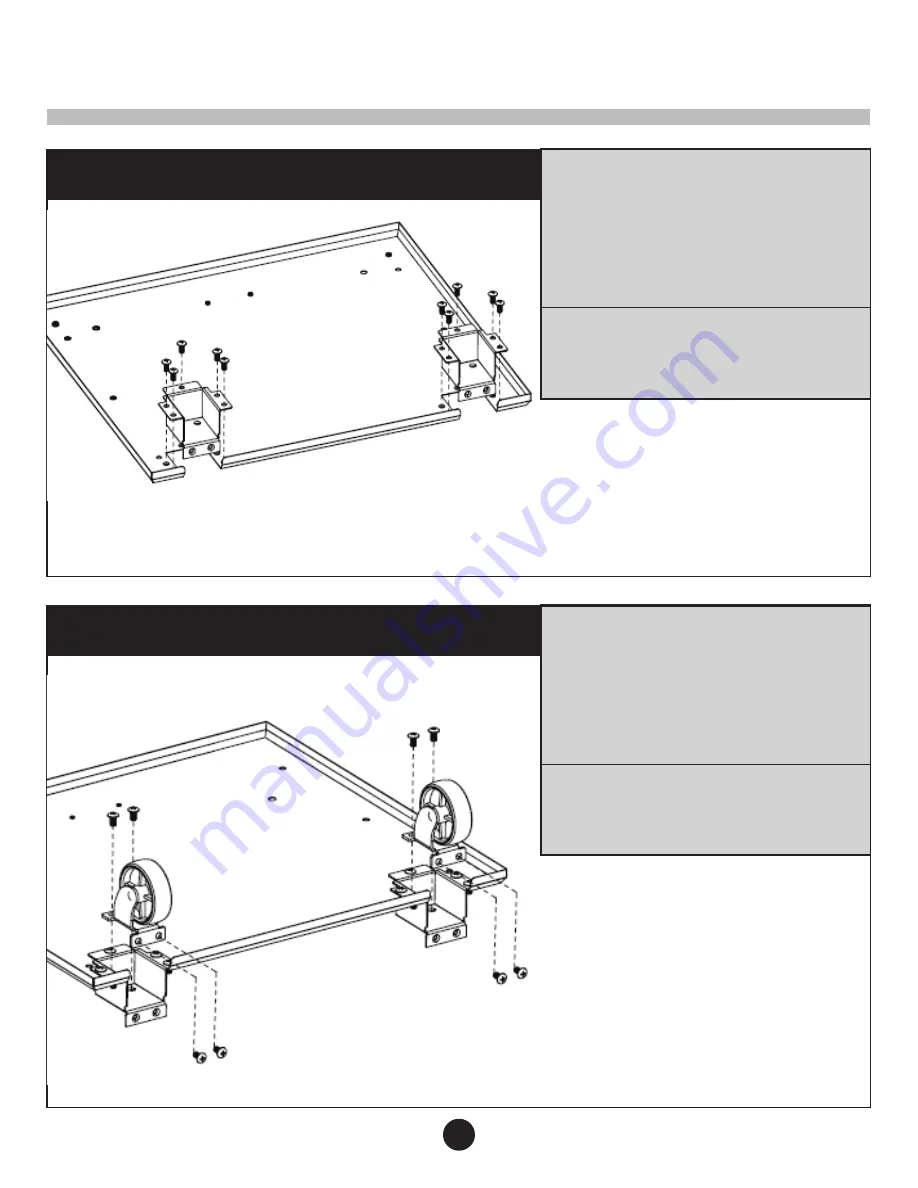

Smoker Assembly

Locate:

• (1) Cabinet Bottom Panel

Assembly

• (2) Wheel Mounting Brackets

• (10) M6 x 20 bolts

Tools Needed:

Phillips Screwdriver

Locate:

• (1) Cabinet Bottom Panel

Assembly

• (2) Wheel Assembly

• (8) M6 x 20 bolts

Tools Needed:

Phillips Screwdriver

Procedure:

Use (8) M6 x 20 bolts to assemble

the (2) Wheel Assembly to the

Cabinet Bottom Panel Assembly

as shown.

Step 1

Step 2

Procedure:

Use (10) M6 x 20 bolts to assemble the (2) Wheel Mounting

Brackets to the Cabinet Bottom Panel as shown.

7