Outdoor Lifestyles by Hearth & Home Technologies • Installation Manual TWILIGHT-II-MOD • 2290-970 Rev. F • 11/13

24

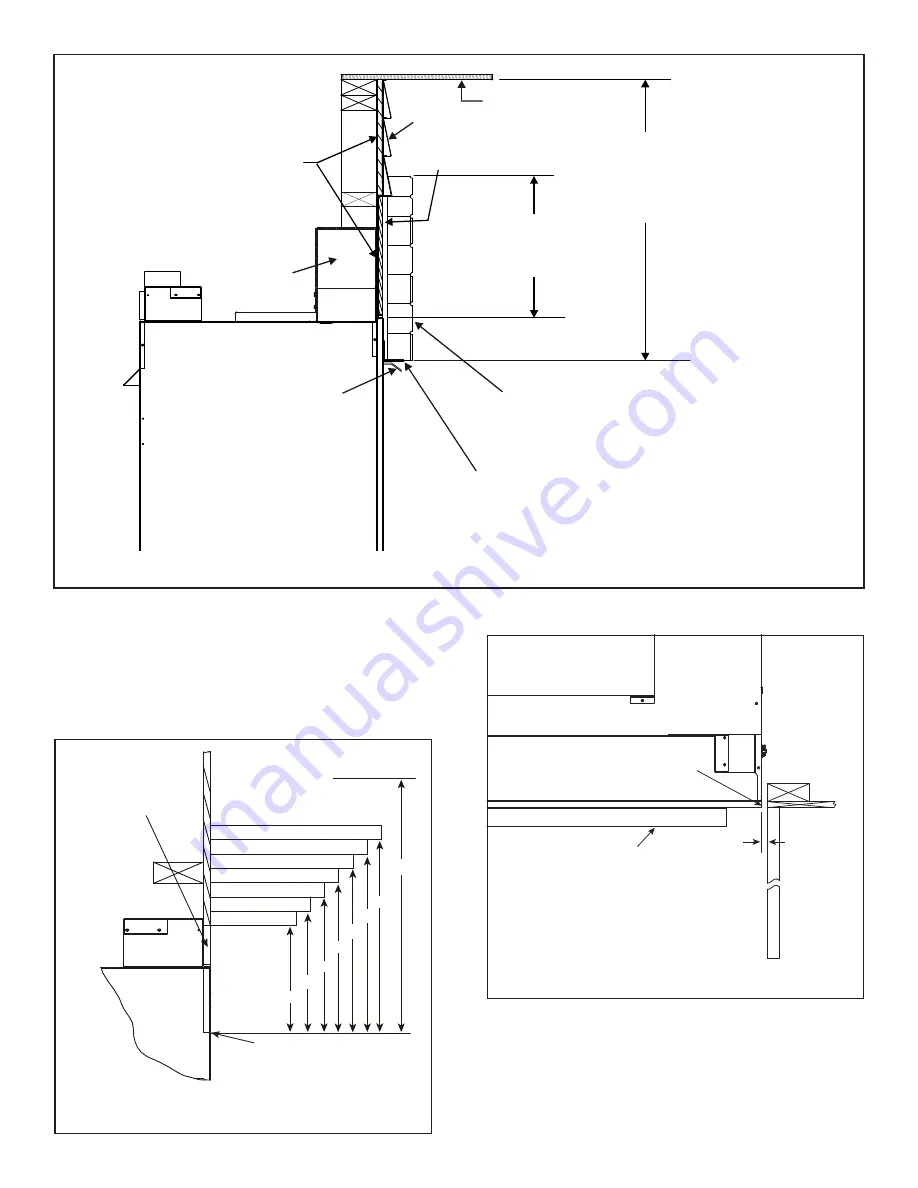

C. Door Dimensions for Finishing

Only doors certi

fi

ed for use with this appliance model may

be used. Contact your dealer for a list of doors that may

be used.

B. Mantel and Wall Projections

WARNING! Risk of Fire!

Comply with all minimum clear-

ances as speci

fi

ed. Framing closer than the minimums list-

ed must be constructed entirely of noncombustible materi-

als (i.e., steel studs, concrete board, etc.) Failure to comply

could cause

fi

re.

12

11

10

9

8

7

6

13-5/8

12-5/8

11-5/8

10-5/8

9-5/8

8-5/8

7-5/8

HOOD

NON-COMBUSTIBLE BOARD

(SUPPLIED ON APPLIANCE)

INDOOR SIDE ONLY

CEILING

35-3/4

MEASUREMENTS FROM

TOP EDGE OF THE OPENING

MEASURED

FROM CORNER

TOP VIEW

FIREPLACE

HOOD

1/2 IN.

Note:

Measurements are in inches.

Figure 8.6 Clearances to a Combustible and/or Non-combustible

Indoor Mantel

Figure 8.7 Clearances to a Combustible and/or Non-combustible

Indoor Mantel or Mantel Leg

APPLIANCE

HOOD

TOP OF

APPLIANCE

SOFFIT

SIDING

HOUSEWRAP (BUILDING

PAPER) AND SHEATHING

35-5/16 in.

MINIMUM CLEARANCE

TO NON-VINYL

64-5/16 in.

CLEARANCE TO VINYL

SOFFIT, OVERHANG, MANTEL,

OR CEILING

12 in.

MINIMUM CLEARANCE

TO NON-VINYL SIDING

36 in. MINIMUM

CLEARANCE TO VINYL SIDING

DRAIN PLANE

DETERMINED BY

LOCAL CODE

BRICK OR OTHER NON-COMBUSTIBLE

FACING MATERIAL 6 INCH MAXIMUM

PROJECTION FROM SURFACE OF

FIREPLACE (INCLUDES NON-COMBUSTIBLE

MANTEL PROJECTION)

NON-COMBUSTIBLE BRICK LEDGE

MUST BE TIGHT TO APPLIANCE

FACE OR NON-COMBUSTIBLE SHEATHING

TOP OF HOOD

INSULATION

Figure 8.5 Exterior View with Non-combustible Facing Material

DETAIL -

SEE FIGURE 10.5