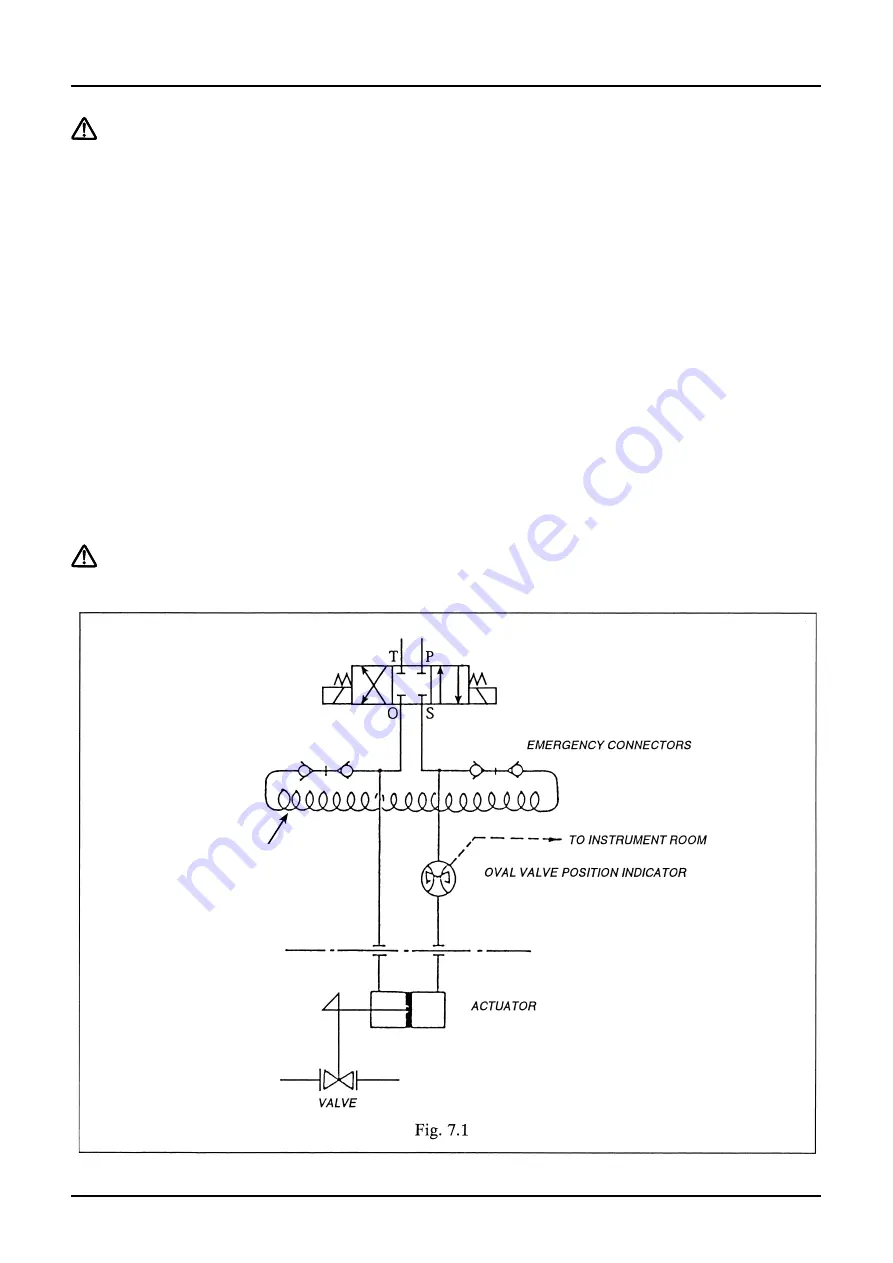

BYPASS CIRCUIT

S-156-3-E

1

7. OPERATING PRECAUTIONS

Prior to operating the valve, it is necessary that all air or vapor contained in the process line be thoroughly

removed. Air or vapor, if admitted in the line in large quantities, will produce an error of valve position

indication.

1. Symptoms associated with the presence of excessive air or vapor in the line:

① At the moment the hydraulic directional valve is switched over, the pointer may register an abrupt

swing.

② Pointer movement is not smooth but intermittent during valve actuation.

③ Despite the pointer has reached the end of scale either at “SHUT” or “OPEN” point, Oval rotors continue

revolving; the pointer remains slipping for some time.

Symptoms above are indicative of excessive air or vapor in the line. Bleed the line of air or vapor according to

the following procedure.

2. Air Bleeding

Making use of emergency connectors provided in individual hydraulic stands, arrange a bypass circuit as

shown below and allow the fluid to circulate.

Circulate the oil for about 40 minutes while switching the hydraulic directional valve to SHUT and OPEN

alternately. In case of a valve coupled to a tank, for example, where, depending on loading conditions, you

cannot switch operation to the OPEN, perform air bleeding on the SHUT side only.

WARNING: Extra care must be taken in this case to prevent faulty operations sequence which could

result in accidents.