B-526-10N-E

34

10.2.2 Assembly

The assembly procedure is essentially reverse of the removal procedure except for some difference in the

order.

(1) Apply turbine oil to the bearing bore and install two rear bearing holders (208). Then install blind cover (105)

in alignment with match marks. Do not forget to install O-rings (211 and 112).

NOTE:

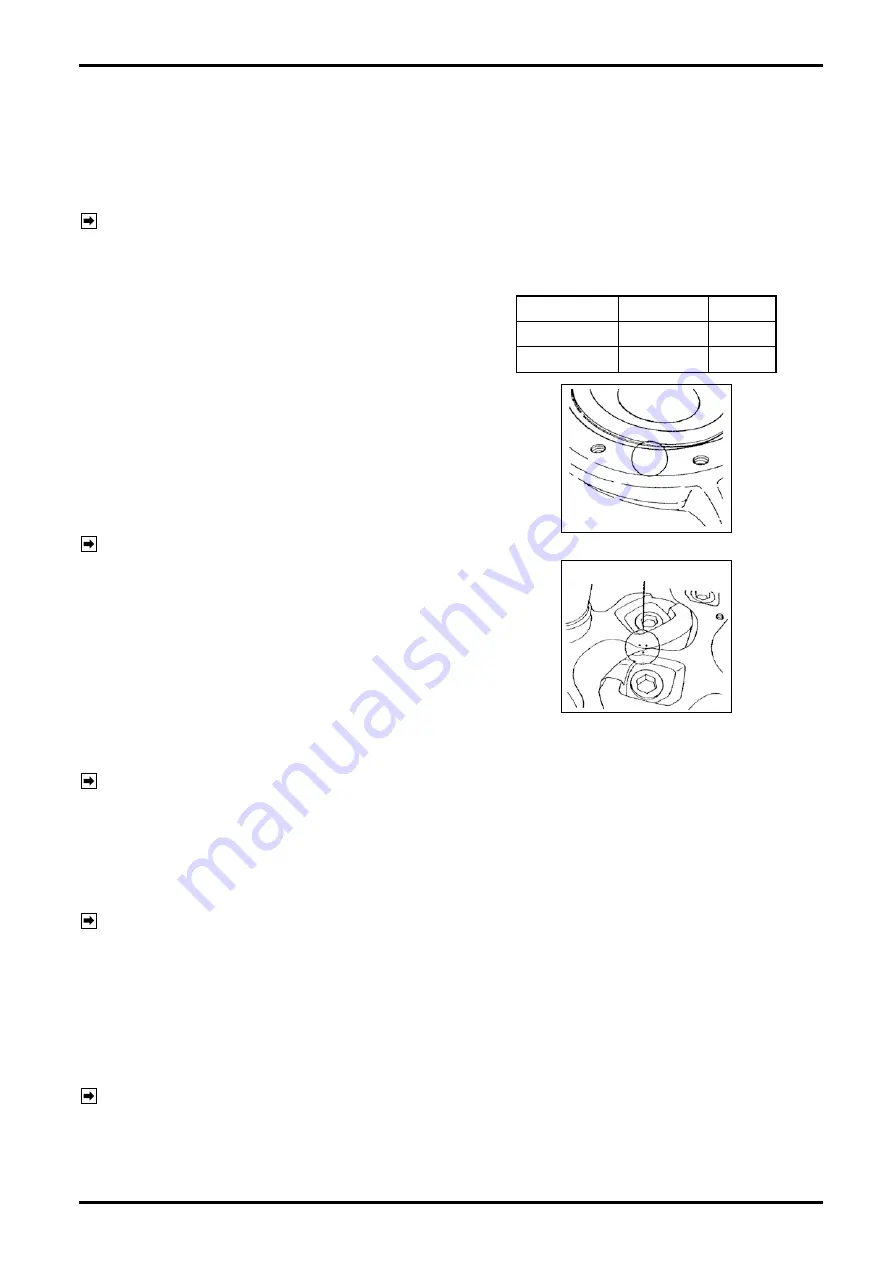

①

Individual bearing holders are identified by metal stamped numbers: install the one in place with the

same number metal stamped on the rear cover.

②

Install the non-turn pin of bearing holder in

line with the non-turn opening in the rare

cover (103).

③

Do not fail to install the O-ring (211) for

bearing holder. Failure to install it in place will

cause rotor seizure. Thoroughly clean

individual component parts. Keep grit and

grime out at reassembly.

(2) Place the meter body upside down with the rear

cover down (place horizontally on supporting

blocks).

(3) Apply turbine oil on rotor shafts and install the

rotors.

NOTE:

①

Be sure to align match marks at rotor

installation as shown.

②

Exercise care to avoid bumping the edges of

bearing shaft (203) while fitting the shaft into

the bearing.

Using a chain block, carefully lower the rotor

being guided by the measuring chamber.

(4) Install the front cover (102). Place it on the meter

body in line with match marks. (Ensure that an

O-ring is in place.)

NOTE:

①

Care should be taken to avoid bumping against the shaft and thrust ring

②

Drive in locating pin (107) firmly.

(5) Tighten hex bolts and then install thrust ring.

(6) Apply turbine oil to the bearing bore and, making sure of the identification number of bearing holder (208),

install in place.

NOTE:

①

Ensure that bearing holders are in place with their identification numbers matched.

②

Do not forget to install an O-ring (211) in place.

(7) Install the adapter (104) and bearing blind cover (105) in line with their match marks.

(8) Place the meter body sideways on the base.

(9) Confirm the rotation of rotors

Using a wooden rod or similar object, apply it to the gear teeth through the meter inlet/outlet opening and

move the rotors to make sure of their rotation, perhaps heavy to move them, though.

NOTE:

See pages 30 and 31 for the procedure to recondition rotor gear teeth and the precautions at signal magnet

disassembly and reassembly, Sizes 82 and 83.

Table 10.3 Bearing Numbers

Register side Rear side

1st rotor

1

3

2nd rotor

2

4

1

MATCH MARKS

Summary of Contents for ULTRA UF-II

Page 67: ...B 526 10N E 67...