B-526-10N-E

50

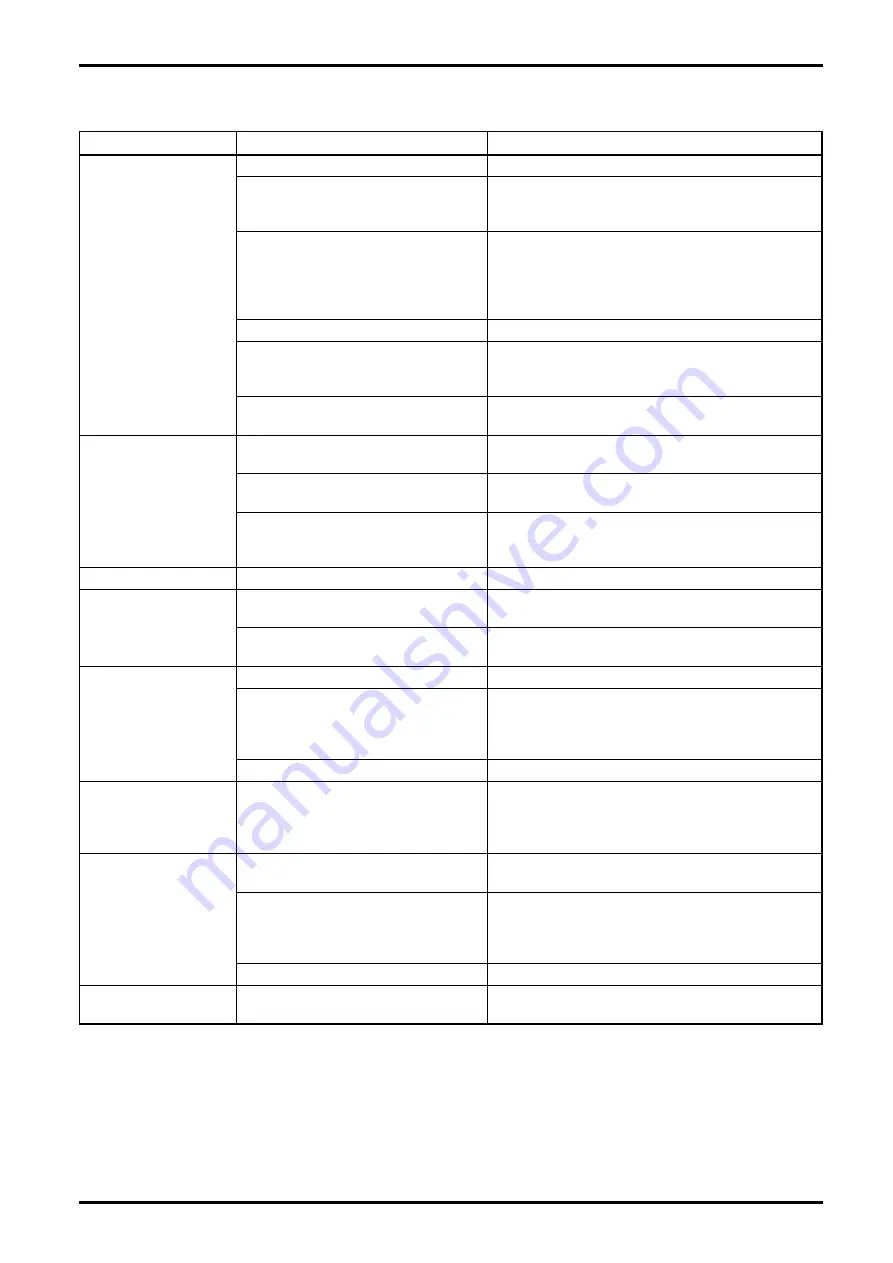

15. TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

COPING ACTION

1. Totalizer will not

count.

1. Flowrate is low.

1. Open valves progressively.

2. Insufficient pump pressure or head

pressure.

2. Taking pressure loss of entire piping assembly into

consideration, correct pump pressure or head

pressure.

3. Power line voltage is out of

specification or current carrying

capacity of power source is

inadequate.

3. Provide a 14-45VDC power to the register. (12 to

24VDC for open collector or voltage pulse output.)

Current carrying capacity 30mA min. is required

for power. (With analog output equipped register,

24VDC, 60mA min. is required.)

4. Battery has run down.

4. Referring to Section 13, replace batteries.

5. OVAL rotors jammed with foreign

matter; rotors locked; metered liquid

fails to run.

5. Referring to Disassembly and Inspection

Procedure (Sec. 10), disassemble meter body and

clean the rotors thoroughly.

6. Sensor installed out of position.

6. Refer to "How to Change Flow Directions" (Sec. 7)

and reinstall the sensor.

2. Unusual noise.

1. Air is entrapped.

1. Decrease flowrate and eliminate air in the piping

assembly.

2. Vaporized metered liquid in the

piping assembly.

2. Decrease flowrate and control metered fluid

temperature and pressure to prevent vaporization.

3. OVAL rotors revolving in contact with

measuring chamber.

3. Refer to Disassembly and Inspection Procedure

(Sec. 10) and disassemble and inspect for

condition.

3. "BATT" flickers.

1. Battery voltage is low.

1. Refer to Sec. 13 and replace batteries.

4. Liquid leaks.

1. Incomplete seal of the pipeline.

1. Inspect rear cover fitting bolts for tightness or

replace gaskets.

2. Incomplete seal on rear cover of

meter body.

2. Retighten bolts at pipeline connections and

replace O-ring with new one.

5. Counts while valve

remains closed.

1. Valve and pipeline leaks.

1. Inspect valves and pipeline.

2. Air pockets between valve and OVAL

meter; rotors in rocking motion in

response to pump's pulsating

pressure.

2. Vent air.

Provide a check valve and accumulator.

3. Supply power voltage fluctuates.

3. Eliminate voltage fluctuation.

6. Analog output

unusual.

1. Load resistance too great.

1. Referring to "Load Resistance Range" on pages

22 and 23, check load resistance to power supply

voltage relationship and keep them within the

specified range.

7. Accumulated total

too high.

1. Rotors in rocking motion in response

to a pulsating flow.

1. Add a check valve and accumulator.

2. Influenced by external magnetic

fields (Meter sensor picks up

external magnetic fields created by a

motor, generator, etc.)

2. Keep out external magnetic fields.

3. Air entrapped.

3. Provide an air vent.

8. Accumulated total

too low.

1. Influenced by external magnetic

fields.

1. Keep out external magnetic fields.

Summary of Contents for ULTRA UF-II

Page 67: ...B 526 10N E 67...