Further advice regarding corrosion protection

NOTICE

High fluid temperatures (> 60 °C) increase the risk of corrosion

f

Do not set the hot water temperature or the heating water flow temperature too high.

NOTICE

Long periods of stagnation increase the risk of corrosion

f

Flush the system on a regular basis – either manually or automatically – if regular long periods of stagna-

tion are to be expected (VDI/DVGW 6023).

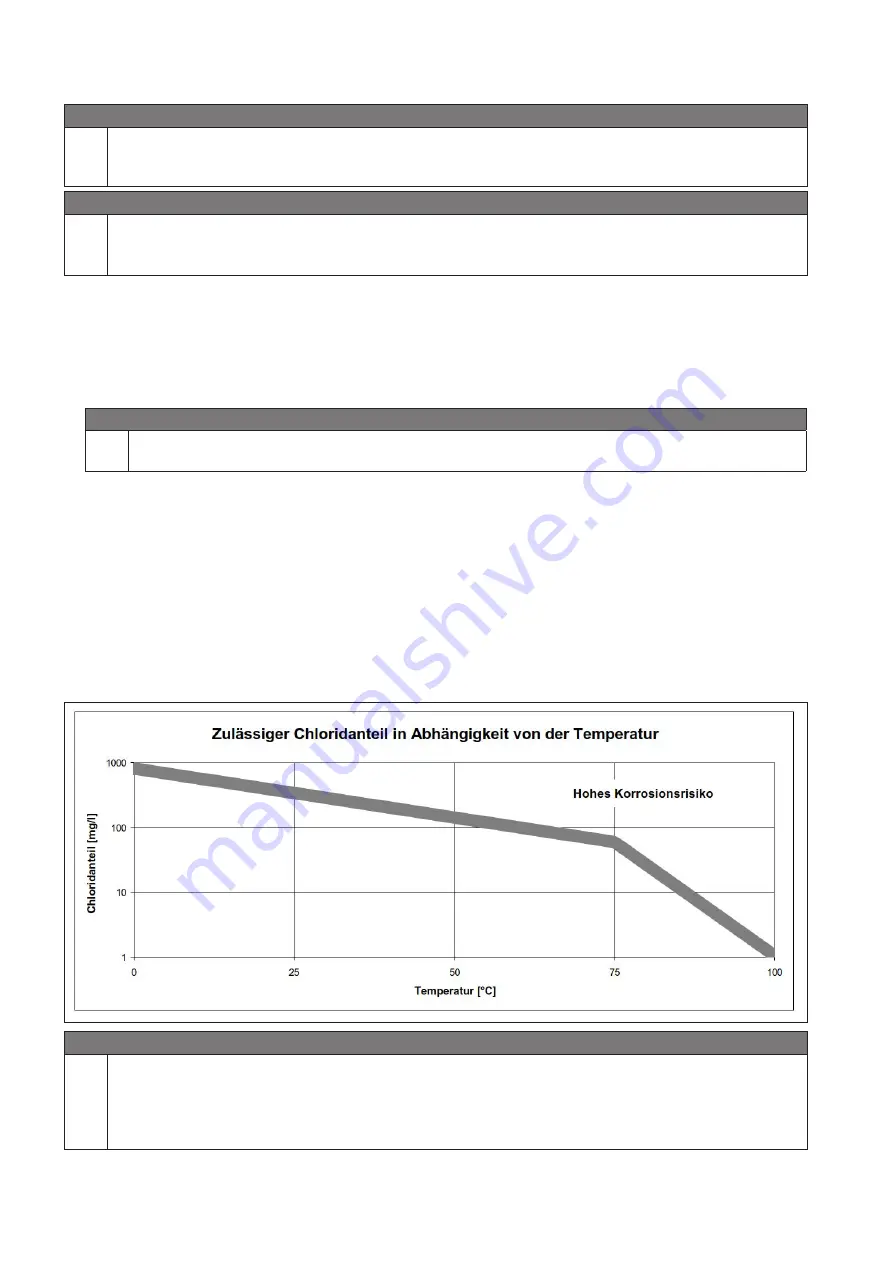

• As a fundamental rule, you should take particular care when combining hydrogen carbonate and chloride.

Low

hydrogen carbonate content combined with high a chloride content increases the risk of corrosion.

• Take particular care when combining hydrogen carbonate and sulphate

. If using copper-brazed heat exchang-

ers, the hydrogen carbonate content in the water must not be less than the sulphate content.

If this does

occur, then a nickel, stainless steel heat exchanger or one with protective layer must be used instead.

• If the thresholds for substances in water are not observed, a

water treatment system

may need to be installed.

NOTICE

If a water treatment system is operated incorrectly, it can increase the risk of corrosion!

•

For mixed installations, the so-called “flow rule” must be observed when using copper-brazed heat

exchangers in conjunction with galvanised steel pipes.

Further information in this regard is provided in

DIN EN 12502.

•

Flush

all of the station’s pipework

before

installation

(DIN EN 806-4) to remove any dirt particles and residues

from the system.

• When performing

maintenance

on the station, remember that

detergents can lead to corrosion of the heat ex-

changer

. Observe the provisions set down by the German Technical and Scientific Association for Gas and Water

(DVGW) in this regard, e.g. Worksheets W291 and W319.

• When using a copper-brazed heat exchanger without a protective layer, the electrical conductivity of the

water varies between 50 and 500 µS/cm

. Bear this in mind in particular in the context of water treatment pursu-

ant to VDI 2035.

NOTICE

Corrosion and scale formation in the system

f

It is the responsibility of the plant engineer and the user of the system to take into account substances in

water and factors that could influence corrosion and scale formation and to evaluate their impact on their

respective situation. It is therefore crucial to consult the local water supply company in advance in areas

where water supply is critical.