SPECIFIC INSTRUCTIONS FOR

WELDING REPAIRS

When repair by welding is authorised by the manufacturer, the

following points shall be taken into account generally.

In particular cases, appropriate welding instructions shall be

provided for each application.

1

Repair welding should be carried out by qualified welders and

in accordance with good technical and safety code practice.

2

Before welding repairs, remove paint, rust, dirt or any other

substances harmful to the weld.

3

To avoid damage to mechanical or hydraulic components such

as bearings, shafts, hydraulic actuators, hydraulic systems, etc.,

care should be taken to place the earth connection in an area of

good contact, free of paint and rust.

On machines with hydraulic cylinders, we must ensure that the

welding current does not flow through such elements. For this

purpose, the earth connection shall be placed on the same part

of the machine to be repaired.

4

Our machines are made of high elastic limit (HEL) steels, which

means that special attention must be paid to welding processes

and filler materials. In general, basic coated electrodes E7016 or

E7018 will be used. For the MAG (semi-automatic) welding

process, ER70S6 wire and Ar+20C02 will be used as shielding gas.

In both cases, follow the recommendations for drying times and

temperatures recommended by the manufacturers of the filler

material.

5

When the parts to be welded are thicker than 15 mm, or the

ambient temperature is lower than 15 C, preheating by flame

between 75-100 C is recommended.

6

It is strictly forbidden to cool welding seams with water, air or

any other substance.

In case of questions during repair, please contact the

manufacturer via the usual means of communication.

5

Summary of Contents for Eurodisc

Page 1: ...EURODISC REV JUL 2021 INSTRUCTIONS AND SPARE PARTS MANUAL ...

Page 17: ...Fig 15 Fig 16 Fig 17 Fig 18 16 ...

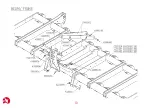

Page 20: ...19 BEAM FRAME ...

Page 22: ...21 BEAM FRAME FOLDABLE ...

Page 24: ...23 HYDRAULIC SYSTEM EURODISC ...

Page 26: ...25 HYDRAULIC SYSTEM EURODISC ...

Page 28: ...27 BODY ...

Page 30: ...29 ROLLER ARM ...

Page 32: ...31 ROLLER ...

Page 36: ...35 DOUBLE ROLLER ...

Page 38: ...37 V ROLLER ...

Page 40: ...39 RUBBER ROLLER ...

Page 42: ...41 LEAF SPRINGS ROLLER ...

Page 44: ...43 T RING ROLLER ...

Page 48: ...47 REAR DEFLECTORS ...

Page 50: ...49 POSITIONING OF DEFLECTORS ...

Page 51: ...50 ...

Page 52: ...51 SIDE DISC ...

Page 54: ...53 LATERAL WHEELS ...

Page 56: ...55 FIX EURODISC TRAFFIC LIGHT KIT ...

Page 58: ...57 FOLDABLE EURODISC TRAFFIC LIGHT KIT ...

Page 60: ...59 FRONT TRAILING KIT ...

Page 62: ...61 FOLDING AUTOMATIC LOCKER ...

Page 64: ...63 REAR TRAILING KIT ...

Page 66: ...65 HYDRAULIC SYSTEM TRAILING KIT ...

Page 68: ...67 FRONT WHEEL EURODISC 21 ...

Page 70: ...69 FRONT WHEEL EURODISC 21 ...

Page 72: ...71 FRONT SIGNALING KIT ...

Page 74: ...73 REAR SIGNALING KIT ...