Repair

22

313294D

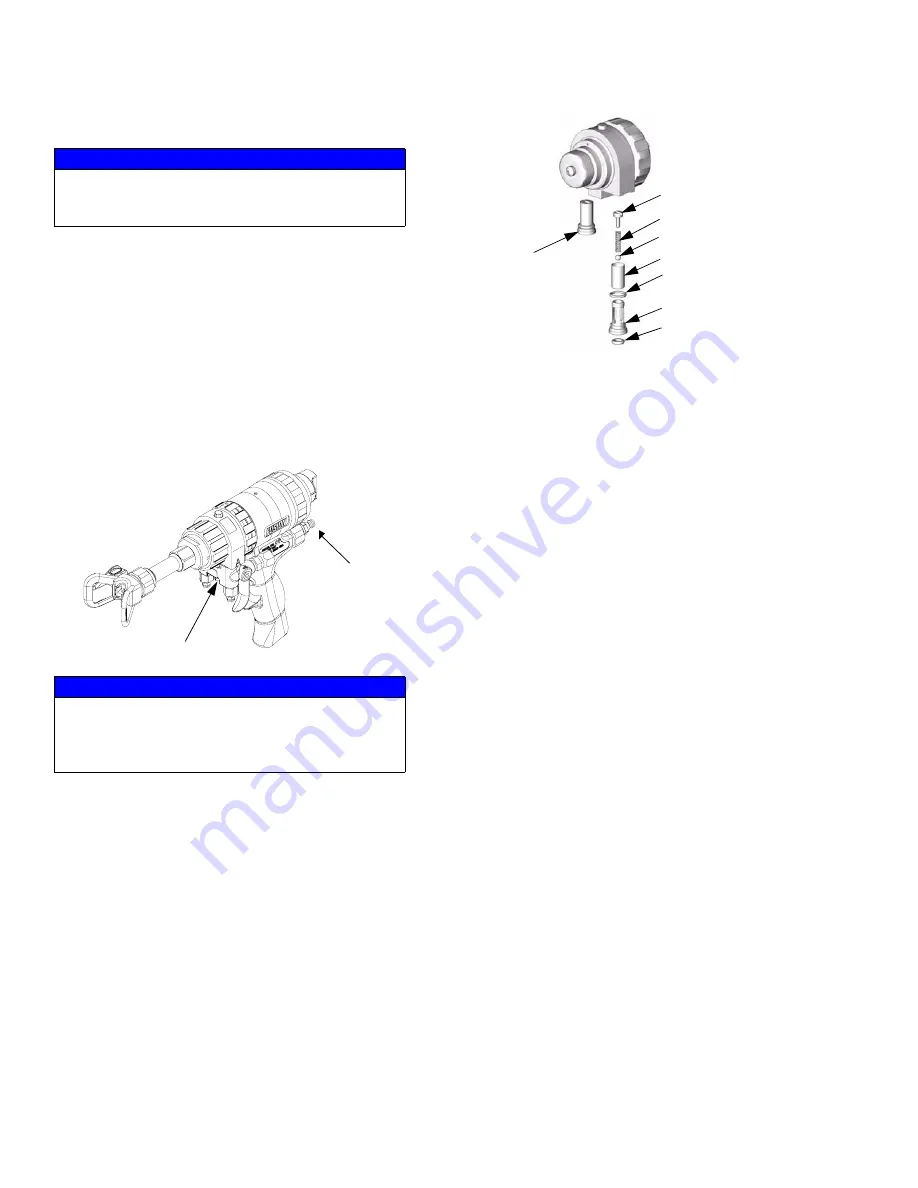

Check Valves

NOTE:

Before disassembling, press on ball (36c) to test check

valve for proper movement and spring action.

1.

Follow Pressure Relief Procedure, page 10.

2.

Flush Gun, page 14.

3.

Disconnect air hose from quick disconnect (D) and

remove fluid manifold (G). Clean and inspect check

valve mating surfaces and fluid ports.

4.

Pry out check valves (39) at notch.

5.

Slide filter (39d) off. Clean and inspect parts. Thor-

oughly inspect o-rings (39f, 39g). If necessary,

remove screw (39b) and disassemble check valve.

6.

Reassemble check valves. Screw (39b) should be

flush (within 1/16 in. or 1.5 mm) of housing (39a)

surface. Liberally lubricate o-rings (39f, 39g) and

carefully reinstall in fluid housing.

7.

Attach fluid manifold. Connect air. Return gun to

service.

NOTICE

Damaged check valve o-rings (39f, 39g) may result

in external leakage. Replace o-rings if any damage

is seen.

NOTICE

To prevent cross-contamination of the check valves,

do not interchange A component and B component

parts. The A component check valve is marked with

an A.

D

r_256998_313294_1b

G

39b

39

B

A

39e

39c

39d

39g

39a

39f

TI4987a