39

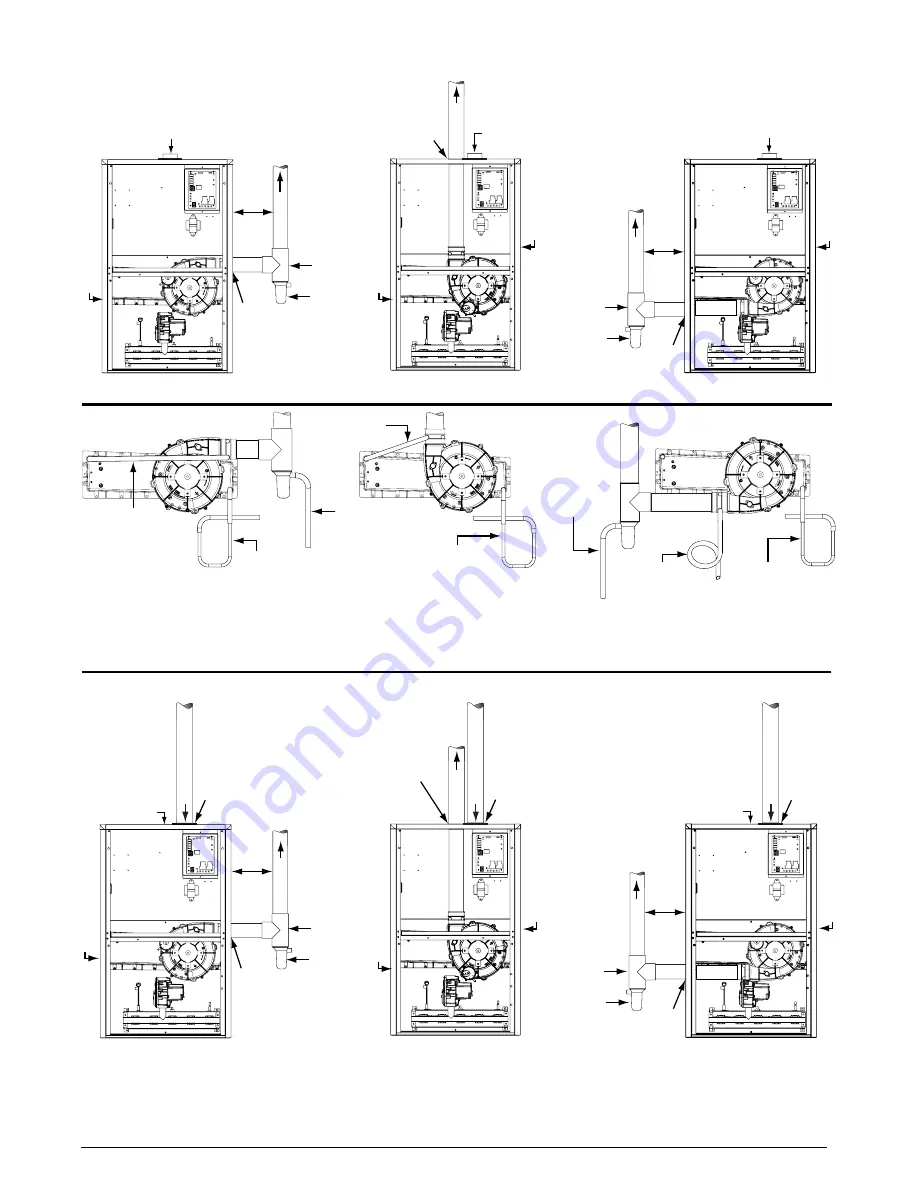

Figure 36. Venting Options for Downflow Installations (J951X*D Series)

Option

9

VIEW -E-

VIEW -G-

Plug

Plug

Plug

Option

12

VIEW -F-

Option

10

Plug

Plug

Option

13

Plug

Plug

J951X*D SERIES DOWNFLOW - 1 PIPE OPTIONS

PVC Tee

COMBUSTION

AIR

FLUE PIPE

FLUE PIPE

COMBUSTION

AIR

Rubber

Grommet

See VIEW E for drain line positions

See VIEW F for drain line positions

See VIEW G for drain line positions

See VIEW G for drain line positions

FLUE PIPE

Rubber

Grommet

COMBUSTION AIR

Plug

Flange

Flange

See VIEW F for drain line positions

FLUE PIPE

Plug

Flange

COMBUSTION AIR

See VIEW E for drain line positions

Rubber

Grommet

Rubber

Grommet

Rubber

Grommet

J951X*D SERIES DOWNFLOW - 2 PIPE OPTIONS

Plug

COMBUSTION

AIR

FLUE PIPE

Option

11

FLUE PIPE

Option

14

COMBUSTION AIR

Inline Drain

(Factory Supplied)

See NOTE 4

Collector Box Drain

(Factory Equipped)

See NOTE 2

Inline Drain

(Factory Supplied)

See NOTE 4

PVC Trap

PVC Tee

PVC Trap

PVC Tee

PVC Trap

PVC Tee

PVC Trap

Collector Box Drain

(Factory Equipped)

See NOTE 2

Collector Box Drain

(Factory Equipped)

See NOTE 2

Inline Drain

(Field Supplied)

See NOTES 2 & 3

X

See

NOTE 5

X

See

NOTE 5

X

See

NOTE 5

X

See

NOTE 5

Rubber

Grommet

Field Supplied

Drain Line Attached

to PVC Trap

(Do Not Trap)

Field Supplied

Drain Line Attached

to PVC Trap

(Do Not Trap)

NOTES

) for optional PVC Tee configurations and drainage options.

2. Drain lines must be trapped with a J-Trap or field supplied loop. Traps may be positioned inside or outside the cabinet. All drain lines must be routed externally

from the cabinet.

3. Inline drain is required only if “X” is greater than 6 feet.

4. Tubing needs to be cut to length and attached during unit installation.

5. Horizontal piping from inducer to flue pipe must be sloped 1/4” per foot to ensure drainage to PVC trap.