Microstat He Manual

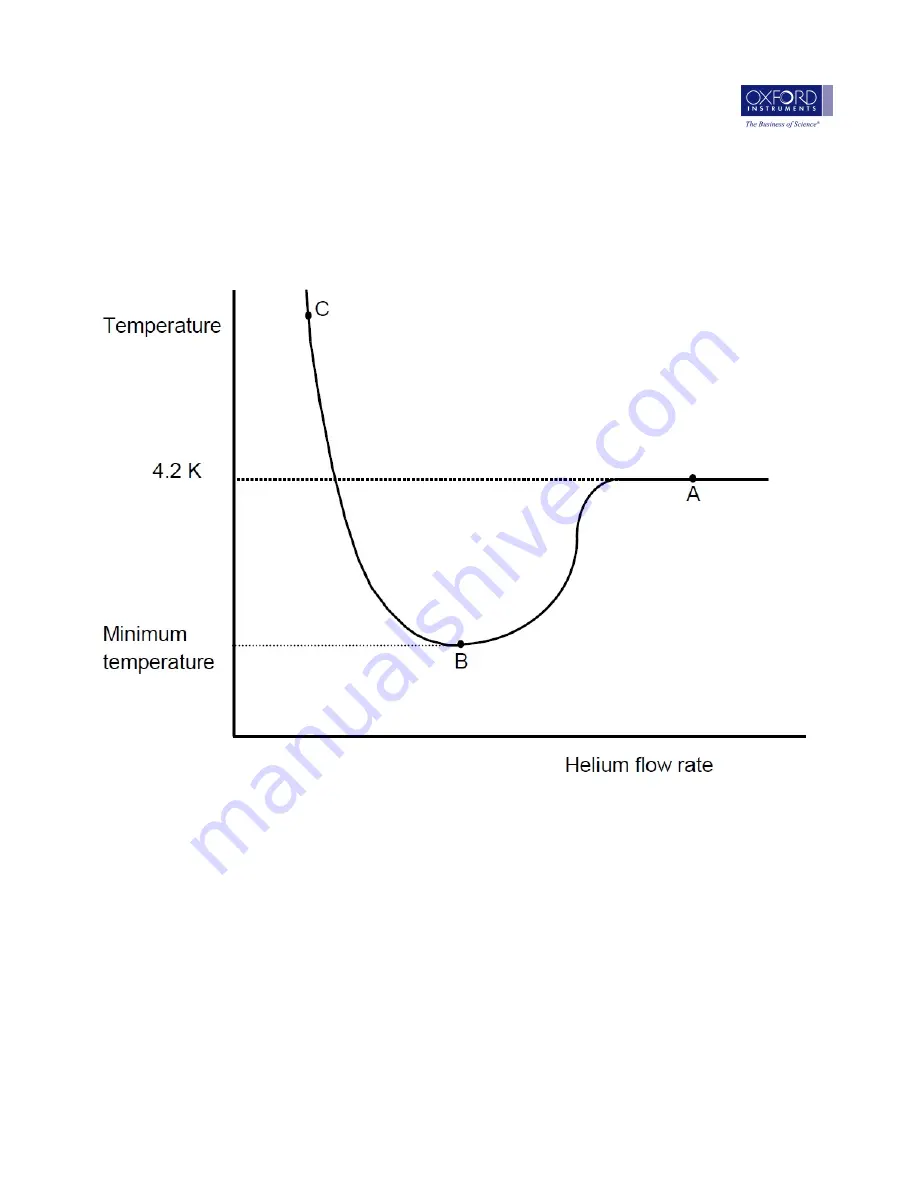

The dependence of temperature on flow rate is illustrated below. It is important for continuous operation at low temperatures that the

cryostat is not running in single shot mode, i.e. with a pool of excess liquid Helium in the heat exchanger. To prevent this, use the following

procedure:

Put the heater control and the gas flow control of the Mercury iTC temperature controller into

Manual

mode, with zero heater voltage.

Figure 6.1: Optimising the flow rate

When the cryostat has reached 4.2K (point A), close the needle valve on the transfer tube. The temperature will probably fall immediately,

as Helium in the heat exchanger is being boiled off. After a few minutes the liquid will have boiled away and the temperature will start to

rise.

At this point, open the needle valve about a quarter turn. The temperature should stabilise below about 20K (point C). Now open the

needle valve in very small increments, waiting for the temperature to stabilise after each change. As you do this, the temperature will fall,

until you reach the base temperature of the system (point B).

Now select the desired SET temperature on the Mercury iTC, and switch the Mercury iTC heater control to

Auto

.

© 2017 Oxford Instruments Nanoscience

MAN-MHE-1.1.0 (28ff3d8) Sep 2017

21