Installation instructions

13

PROTECTING THE FUTURE

IT IS STRICTLY FORBIDDEN:

to use compounds and liquids for cleaning the article, which are

chemically aggressive for materials of the body.

4. Installation of the turnstile

CAUTION!

The turnstile shall be reliably installed so as to avoid its

oscillation and/or capsizing in operation. If the turnstile is to be installed

on floors with low strength, take measures to reinforce the floors in the

place of installation.

Carefully study the present section of the Instructions before starting to

check the operability.

4.1. Necessary equipment

Equipment to be used for installation of the turnstile:

electric drilling machine;

18 mm-diameter carbide drill for boring anchor openings in a

floor (it is recommended to use a sleeve anchor with the bolt

FH 11-S 18/10);

19-mm wrench;

19-mm key wrench with a lever;

flat blade screwdriver;

plumbing line or mechanic’s level;

steel shims for adjustment of the turnstile;

round file;

side-cutting pliers;

500 g hammer;

Summary of Contents for Praktika T-10

Page 2: ...PROTECTING THE FUTURE...

Page 7: ...Installation instructions 7 PROTECTING THE FUTURE Fig 1 Initial position of the leaves...

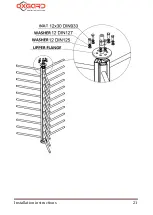

Page 21: ...Installation instructions 21 PROTECTING THE FUTURE...

Page 26: ...Full height turnstile Oxgard Praktika 10 T 10H 26 PROTECTING THE FUTURE Fig 14 220 V 12 V...

Page 37: ...Installation instructions 37 PROTECTING THE FUTURE Fig 21 Sample for turnstile installation...

Page 39: ...Installation instructions 39 PROTECTING THE FUTURE...