EN pg.11

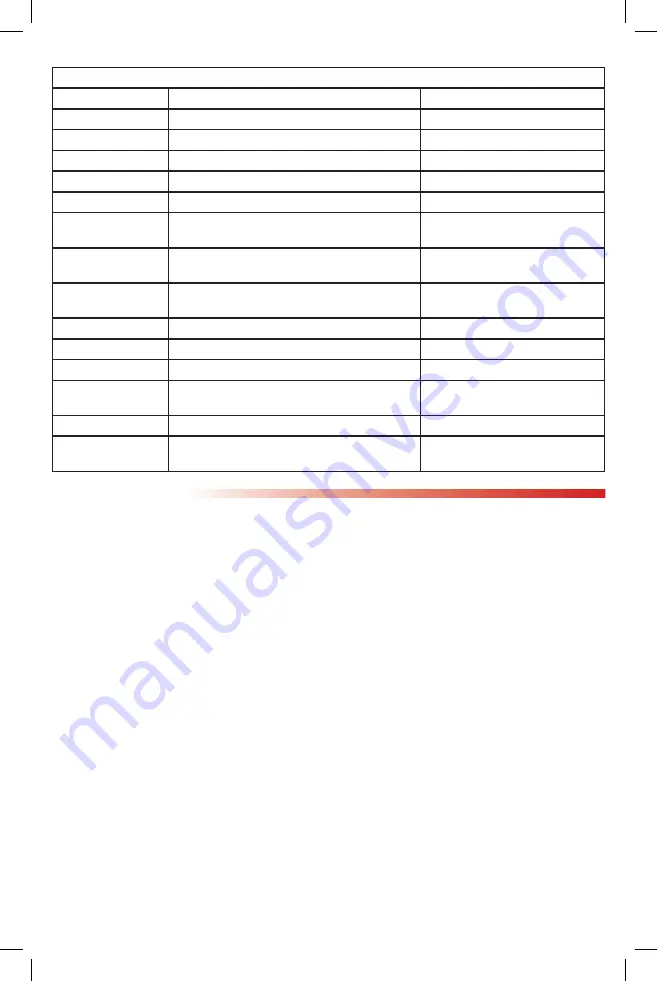

Table 7-1 Lubrication Chart

PART

DESCRIPTION

FREQUENCY

Cables

Check control cables and strain relief elements

Before each shift

Clutch

Check operation of the slipping clutch (if fitted)

Before each shift

Pendant

Check control pendant housing for damage

Before each shift

Hook

Check suspension eye/suspension hook assembly

After 50-200 service hours

Electrical

Check electrical switch gear and wiring

Before each shift, Monthly

Hook

Check tight fit of securing bolts on load hook assembly Before each shift, After 50-200 service

hours

Chain

Check ends of chain/chain bag to ensure they are

secure

Before each shift

Chain

Lubricate chain, under normal usage

Lubricate chain, under heavy usage

After 50-200 service hours

Oil

Check oil level and change oil (if needed)

Before each shift

Hook

Check hooks for cracks, deformation, pitting and wear

After 50-200 service hours

Clips/Bolts/Nuts

Check securing elements for tight fit and corrosion

After 50-200 service hours

Bottom Block

Lubricate chain sprocket bearing and check for a tight

fit of securing bolts.

After 50-200 service hours

Brakes

Check operation of brakes

After 50-200 service hours

Brake

Check brake stroke, brake disc and adjust brake as

required

After 50-200 service hours

8. INSPECTION:

A. GENERAL:

The inspection procedure is based on ANSI/ASME B30.16. The following definitions are from ANSI/

ASME B30.16 and pertain to the inspection procedure below.

1.

Qualified Person: A person who, by possession of a recognized degree or certificate of

professional standing, or who, by extensive knowledge, training and experience has successfully

demonstrated the ability to solve or resolve problems relating to the subject matter at work.

2.

Designated Person: A person assigned or selected as being competent to perform the specific

duties to which he/she is assigned.

3.

Normal Service: A distributed service which involves operation with randomly distributed loads within

the rated load limit or uniform loads less than 65% of rated load for not more than 25% of the time.

4.

Heavy Service: A service which involves operation within the rated load limit which exceeds

normal service.

5.

Severe Service: A service which involves normal or heavy service with abnormal operating conditions.

B. INSPECTION METHODS AND CRITERIA:

This section covers the inspection of specific items. The list of items in this section is based on those

listed in ANSI/ASME B30.16 for the Frequent and Periodic Inspection. In accordance with ANSI/ASME

B30 volumes listed under the General heading on the previous pages, these inspections are not intended

to involve disassembly of the hoist. Rather, disassembly for further inspection would be required if

frequent or periodic inspection results so indicate. Such disassembly and further inspection should only

be performed by a certified or qualified person trained in the disassembly and re-assembly of the hoist.