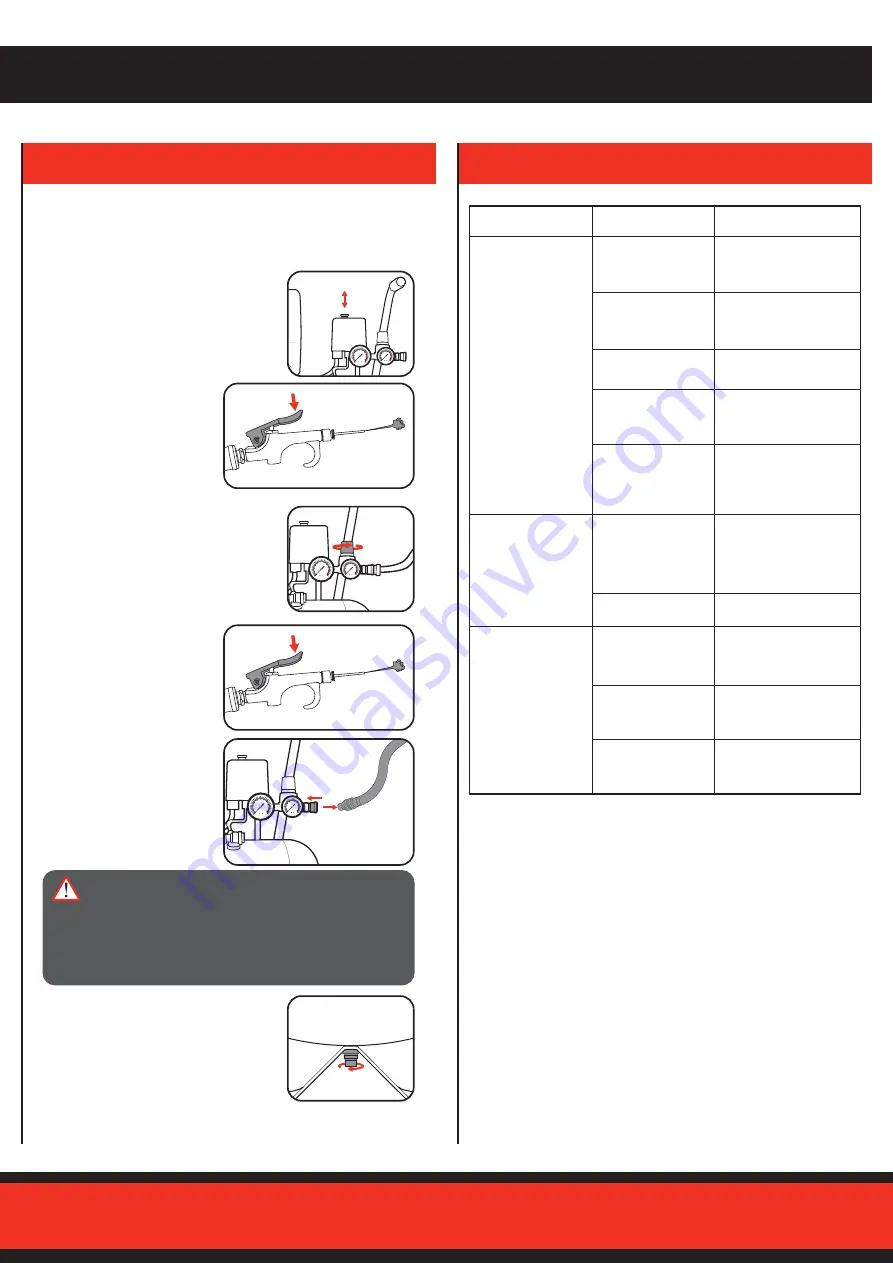

Shutting Down The Compressor

Do not turn the air compressor off by unplugging it from the mains

power as it may result in damage to the motor.

1. Turn the compressor off with the on/off

switch and then unplug the cord.

2. Attach a blow gun to the

compressor and use it to

discharge any remaining air in

the compressor tank.

3. Rotate the pressure regulator anti-

clockwise until it is fully closed; check the

regulated pressure gauge to ensure that it

reads 0psi.

4. Also turn on the air tool to

discharge any remaining

pressurised air in the air hose.

5. Remove the air hose and any

other connected accessories.

WARNING!

RELEASE ALL AIR PRESSURE FROM

THE TANK BEFORE OPENING THE DRAIN VALVE.

TAKE CARE WHEN DISCHARGING AIR THROUGH

THE DRAIN VALVE OR AIR OUTLETS. THE

DISCHARGED AIR CAN CAUSE DUST, STONES, OR

ANY OTHER FOREIGN PARTICLES TO BE BLOWN

THROUGH THE AIR AT HIGH PRESSURE.

6. When no more air is released, open the

drain valve to release any accumulated

liquid from the tank.

7. Close the drain valve, allow the compressor to cool down, then

clean and store the unit.

ACP-4020

4. TROUBLESHOOTING

0

25

50

75

100

125

150

0

(1)00

(3)00

(5)00

(7)00

(9)00

2

4

6

8

10

Lb/in²

(PSI)

kPA

(BAR)

PRESSURE GAUGE

kg/cm²

0

25

50

75

100

125

150

0

(1)00

(3)00

(5)00

(7)00

(9)00

2

4

6

8

10

Lb/in²

(PSI)

kPA

(BAR)

PRESSURE GAUGE

kg/cm²

ON

OFF

0

25

50

75

100

125

150

0

(1)00

(3)00

(5)00

(7)00

(9)00

2

4

6

8

10

Lb/in²

(PSI)

kPA

(BAR)

PRESSURE GAUGE

kg/cm²

0

25

50

75

100

125

150

0

(1)00

(3)00

(5)00

(7)00

(9)00

2

4

6

8

10

Lb/in²

(PSI)

kPA

(BAR)

PRESSURE GAUGE

kg/cm²

0

25

50

75

100

125

150

0

(1)00

(3)00

(5)00

(7)00

(9)00

2

4

6

8

10

Lb/in²

(PSI)

kPA

(BAR)

PRESSURE GAUGE

kg/cm²

0

25

50

75

100

125

150

0

(1)00

(3)00

(5)00

(7)00

(9)00

2

4

6

8

10

Lb/in²

(PSI)

kPA

(BAR)

PRESSURE GAUGE

kg/cm²

Symptom

Possible Cause

Suggested Solution

The compressor

does not start

Compressor has

reached cut-out

pressure

Compressor will

automatically start once

below the cut-in pressure.

No power supply

Check the power supply,

the power plug and the

socket-outlet.

Insufficient supply

power

Reduce length of

extension lead.

Outside temperature

is too low

Never operate with an

outside temperature of

below 5°C.

Motor is overheated

Allow the motor to cool

down. If necessary,

remedy the cause of the

overheating.

The compressor

starts but there is no

pressure

The seals are

damaged.

Check the seals and

have any damaged seals

replaced by a service

centre.

The drainage valve

leaks.

Ensure it is properly

closed.

The compressor

starts, pressure

is shown on the

pressure gauge, but

no pressure to the

air tool.

Loose hose

connections

Check the compressed

air hose and tools and

replace if necessary.

Leak in a quick-lock

coupling

Check the quick-lock

coupling and replace if

necessary.

Insufficient pressure

set on the pressure

regulator.

Open the pressure

regulator further.