5. CLEANING

MAINTENANCE

WARNING!

BEFORE CLEANING YOUR AIR

COMPRESSOR OR CARRYING OUT ANY

MAINTENANCE PROCEDURE, MAKE SURE THAT IT

IS DISCONNECTED FROM THE POWER SUPPLY TO

PREVENT ACCIDENTAL STARTING.

Changing The Oil

The oil should be refilled for the first time after 100 hours of operation.

Thereafter, the oil should be drained and refilled after every 500 hours

of service.

1. Release any accumulated air pressure from the tank and ensure

that it is disconnected from the power supply.

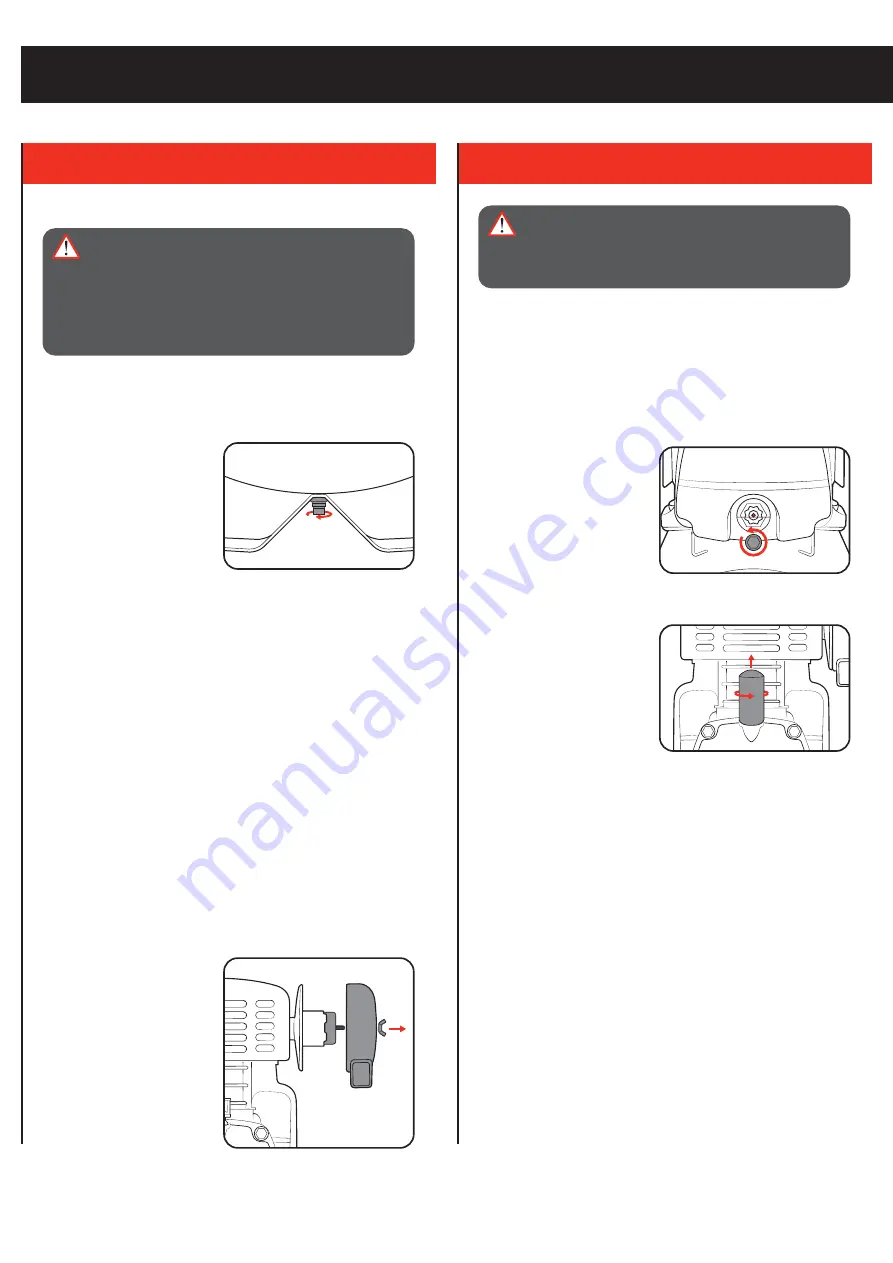

2. Remove the oil drainage

screw and use a vessel to

collect the oil from the unit as

it drains out.

Note:

if the oil does not drain out

completely, the compressor may

be tilted slightly to facilitate this.

3. Reattach the oil drainage screw.

4. Remove the breather plug and

fill the pump with oil up to the

required level (approximately

200ml). Ozito compressor

oil or SAE 15W/40 oil or an

alternative of the same quality

is recommended.

5. Screw the breather plug back

into place.

6. Dispose of the old oil in a responsible manner by taking it to

an old oil drop off point. Check with your local council for more

information. DO NOT dispose of old oil down the drain.

Cleaning

1. We recommend that you clean the appliance immediately after you

use it.

2. Keep the safety devices free of dirt and dust as much as possible.

Wipe the equipment with a clean cloth.

3. Clean the appliance regularly with a damp cloth and some soft

soap. Do not use cleaning agents or solvents; these may be

aggressive to the plastic parts in the appliance. Ensure that no

water can get into the interior of the appliance.

4. You must disconnect the hose and any spraying tools from the

compressor before cleaning. Do not clean the compressor with

water, solvents or the like.

Draining The Pressure Tank

WARNING!

RELEASE ALL AIR PRESSURE

FROM THE TANK BEFORE OPENING THE DRAIN

VALVE. TAKE CARE WHEN DISCHARGING AIR

THROUGH THE SAFETY VALVE, DRAIN VALVE

OR AIR OUTLETS. THE DISCHARGED AIR CAN

CAUSE DUST, STONES, OR ANY OTHER FOREIGN

PARTICLES TO BE BLOWN THROUGH THE AIR AT

HIGH PRESSURE.

Air in the compressor tank causes water to accumulate. This must be

drained off frequently to prevent corrosion and damage to the unit.

This should be performed after each use and prior to the next

use.

1. Turn the drain valve plug

anti-clockwise (when viewed

from the bottom of the tank) to

open it.

2. Allow all of the water in the tank to drain out.

3. Replace the drain valve plug and turn it clockwise to tighten it.

Note:

The tank will not pressurise while the drain valve is open.

Cleaning The Air Filters

The air filters prevent dust and dirt being drawn in. It is essential

to clean these filters at least after every 100 hours in service.

Clogged air filters will decrease the performance of the compressor

dramatically.

1. Allow the compressor to run and build up pressurised air in the

tank. Once the motor has stopped running, turn the compressor off

and disconnect it from the power supply.

2. With an air hose and blow gun connected to the regulated pressure

outlet, turn the pressure regulator until the regulated pressure

gauge shows a pressure of around 3bar.

3. Unscrew the wingnut on the

air filter housing and remove

the lid.

4. Remove the filter sponge from

the housing, tap it and spray

it with the blow gun to remove

any dirt. Re-insert it into the

housing.

5. Re-attach the lid and wingnut.

MAX.

MIN.