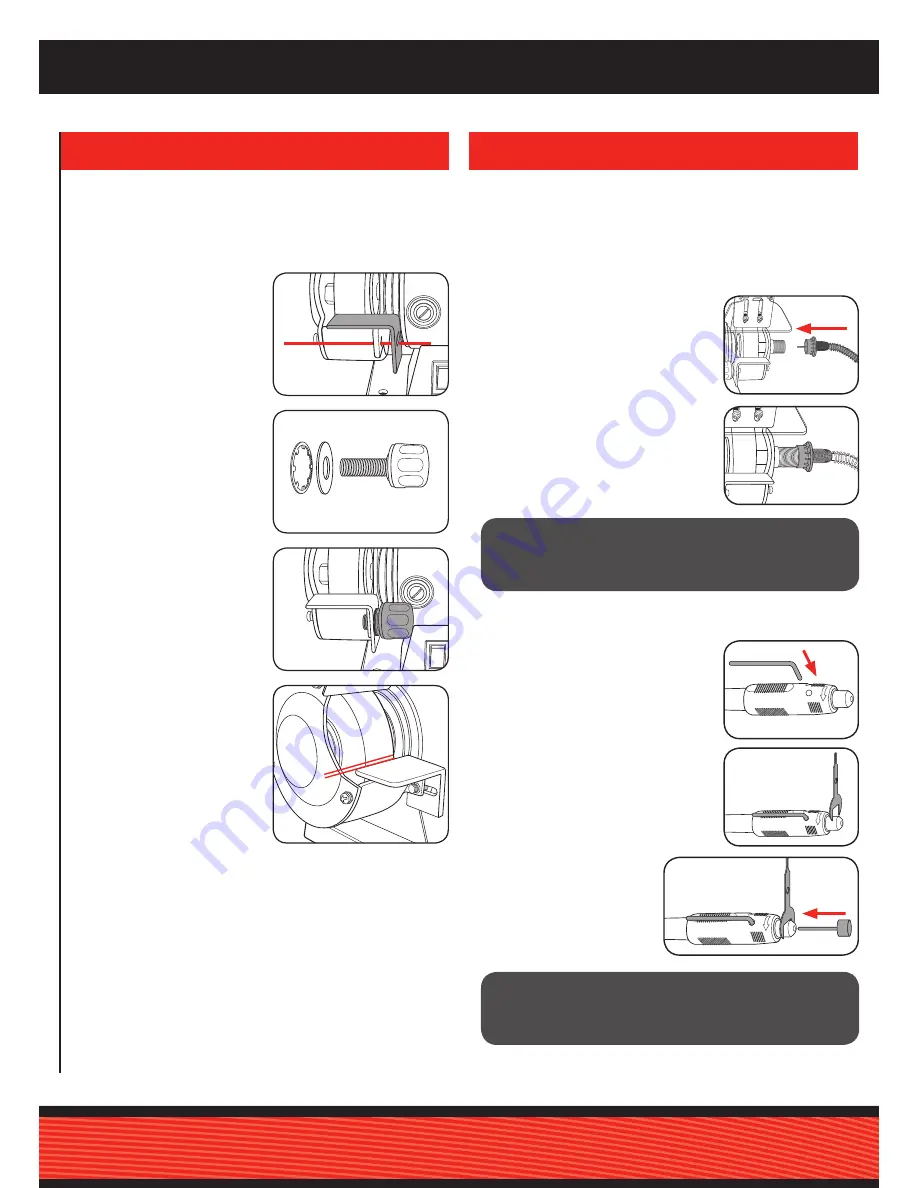

Fitting the Adjustable Tool Rest

The Bench Grinder comes with two adjustable tool rests that aid

the user in holding items steady as they are being applied to the

grinding wheels.

1. Align the slot in the tool rest

with the hole in the bottom of

the wheel guard cover.

2. Place the washers on the

threaded end of the star

screw.

3. Secure the adjustable tool rest

to the grinder using the star

screw. Do not fully tighten until

the final adjustments have

been made.

4. Adjust the tool rest so that the

distance between the grinding

wheel and the tool rest is as

small as possible and does

not exceed 2 mm. Tighten the

star screw.

NOTE:

Adjust the tool rest

periodically to compensate for

wear on the grinding wheel.

2. THE FLEXIBLE SHAFT

IMPORTANT!

WHEN YOU WORK WITH THE FLEXIBLE

DRIVE, THE SAFETY SHIELD MUST BE PLACED RIGHT UP

AGAINST THE ADJUSTABLE TOOL REST IN ORDER TO

PREVENT ACCIDENTAL TOUCHING OF THE WHEELS.

Installing the Flexible Drive

NOTE:

Fitting the accessory flexible drive shaft is optional and should

only be fitted when required.

The flexible drive is designed for the grinding, deburring, polishing,

engraving, cutting, milling and cleaning of wood, metal and plastic

in model making, in workshops and in the home. Use the tool and

its accessories only for the applications

described.

1. Insert the internal shaft of the flexible

drive into the guide shaft on the right

hand side of the grinder.

2. Secure the fastening nut of the flexible

drive to the equipment thread by hand

(left-hand thread).

Inserting the accessories

into the Flexible Drive

1. Press the supplied locking pin into the

hole in the flexible drive and turn the

shaft until the pin latches in place.

2. Undo the collet chuck nut with the

supplied spanner.

3. Insert the required

accessory into the sleeve

and tighten the collet chuck

nut.

IMPORTANT!

ALWAYS DETACH THE FLEXIBLE DRIVE FROM

THE GRINDER WHEN NOT IN USE. AN ATTACHED FLEXIBLE

DRIVE MAY WHIP ABOUT UNCONTROLLABLY IF IT IS NOT

BEING HELD.

2 mm

Max.