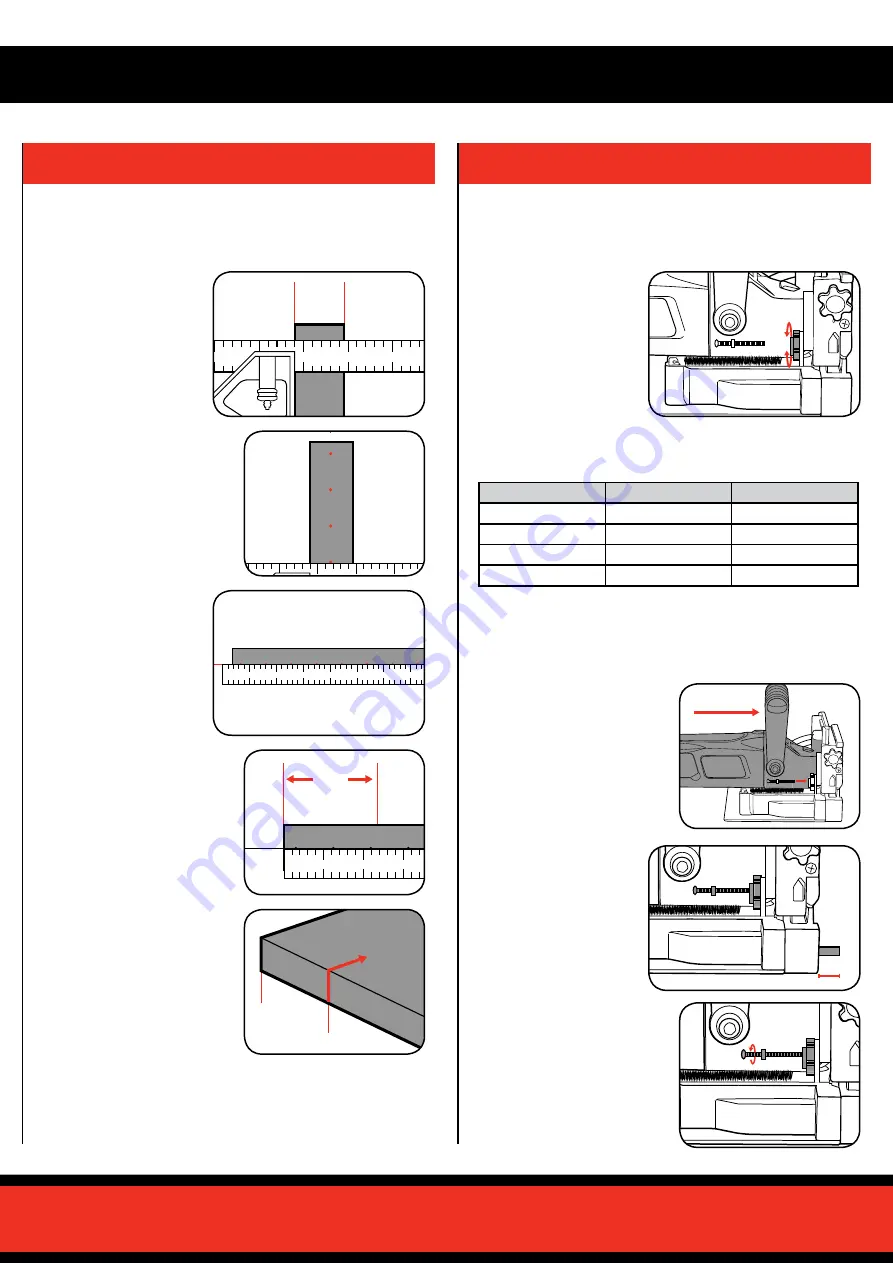

2. MARKING THE WORKPIECE

3. ADJUSTING THE CUTTING DEPTH

Centrelines

1 Measure the width of

your workpiece with a

square.

The centreline of the workpiece and the centreline of the biscuit must

be lined up accurately to ensure a successful joint. The centreline

marking procedure is outlined below.

2 Divide the measurement by 2

to get the midpoint. Mark this

point several times along the

workpiece with a pencil.

3 Using a ruler, mark

the centreline across

the entire face of the

workpiece.

4 Using a square measure, mark

a line 65mm from the edge of

the workpiece.

Note:

65mm is the recommended

distance from the edge

of the workpiece to the

centreline of the biscuit.

5 Using a square, draw a

continuation of the centreline

on the top of the workpiece

for use when aligning the

centreline indicator of your

biscuit joiner.

1 Set the depth adjustment dial

using the procedure above,

then extend the blade until the

depth stop contacts the depth

adjustment dial.

3 To adjust the scale, rotate

the depth stop screw until the

depth of the blade matches the

scale as outlined in the above

table. Repeat this process for

each depth setting.

measure

65mm

65mm

Adjusting the Cutting depth

Checking the Accuracy of the depth Stop

1 Rotate the depth

adjustment dial so that

it clicks into the desired

setting.

2 Measure the distance

between the blade and

the face of the fence.

The depth adjustment dial controls the depth of the cut made in the

workpiece as required for your biscuit.

Your choice of biscuit is dictated by the size of the workpiece. The

following table shows the relationship of the markings on the depth

adjustment dial to cutting depth and the biscuit used.

Note:

It is recommended to check the accuracy of the depth adjustment

dial as part of your setup procedure.

Marking

Biscuit

Cutting depth

0

#0

8mm

10

#10

10mm

20

#20

12.5mm

M

N/A

14mm (maximum)