+

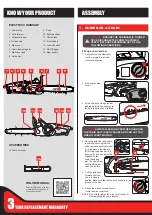

Tensioning the chain

1. Unscrew the side cover

lock a few turns to ensure it is loose.

2. Adjust the chain tension with the

chain tensioning dial. Rotating the

dial downwards increases the tension

and rotating the dial up decreases the

chain tension.

The tension is correct when the chain

can be pulled 3mm away from the guide

bar when using your finger and thumb.

Do not over-tighten as this will reduce

the life of the chain and guide bar.

3. Tighten the side cover lock.

3. LUBRICATION

2. CHAIN TENSION

SETUP & PREPARATION

3mm gap is

the ideal tension

+

+

IMPORTANT!

THE CHAIN SHOULD BE ADJUSTED

BEFORE FIRST USE, AGAIN AFTER 2

–

3 MINUTES

OF OPERATION AND RECHECKED AND ADJUSTED IF

NECESSARY AFTER EACH 30 MINUTES OF USE. TAKE

CARE NOT TO OVER TENSION THE CHAIN.

NOTE:

ONLY USE OIL THAT IS EXPRESSLY LABELLED

“CHAIN BAR OIL”.

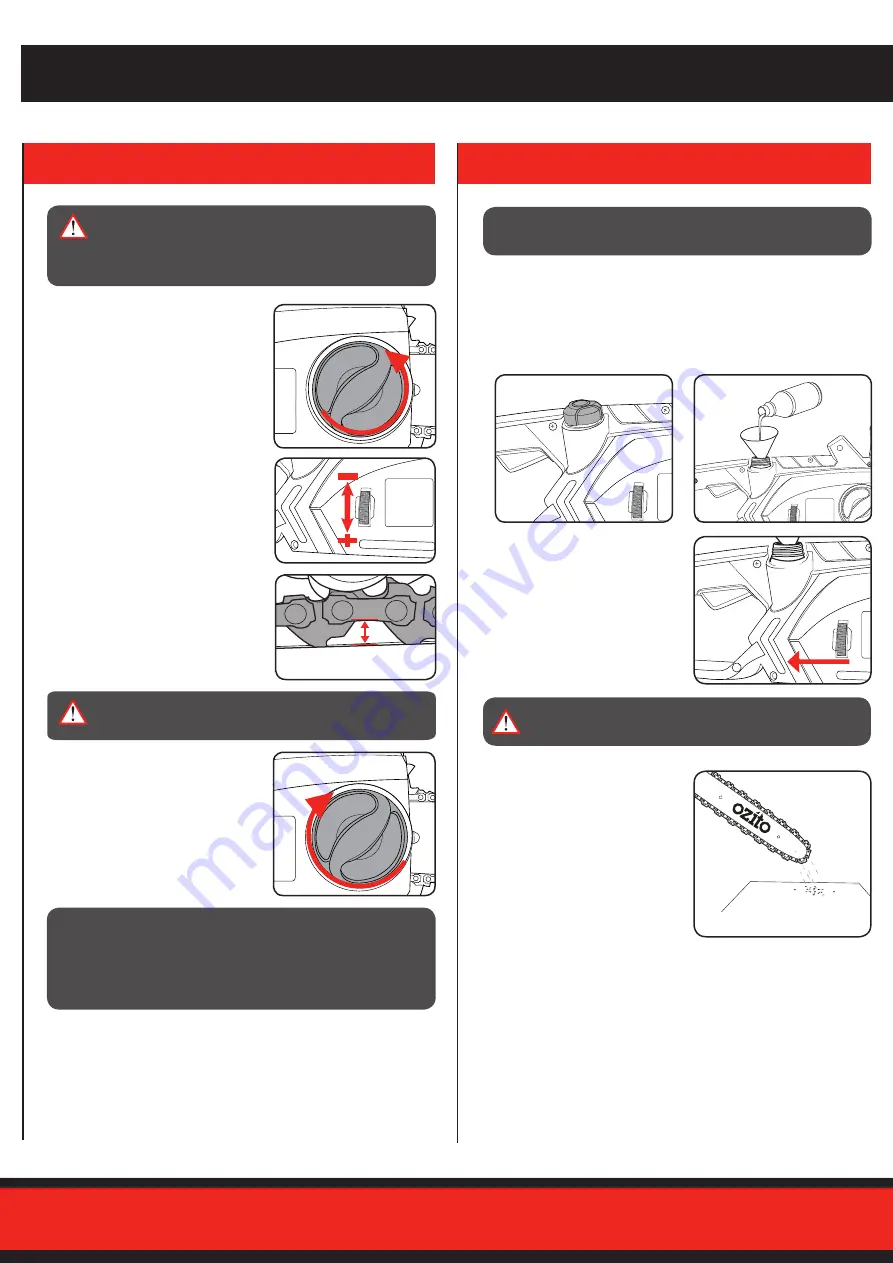

Filling with oil

1. Place the chainsaw on a flat

surface and remove the oil

tank cap.

3. Refit cap and clean any

oil spillage.

4. Always fill the oil tank when the oil

level falls below the minimum mark

on the oil level window.

5. To check the lubricating system,

switch on the chainsaw and hold it

with the guide bar and chain above

some light coloured paper such as

newspaper. A steadily increasing

stain caused by oil spray shows the

lubricating system is working.

Chain bar oil may leak if the tool is

left for long periods. This is normal.

If the tool is to be left unused for an

extended time, drain the oil from

the tool. Refill before use.

2. Fill the tank with chain bar oil,

ensuring that no dirt enters the

tank. The capacity of the chain

oil tank is 160ml.

WARNING!

TO PREVENT ACCIDENTAL STARTING,

ENSURE THAT THE CHAINSAW IS DISCONNECTED

FROM THE POWER SUPPLY BEFORE MAKING ANY

ADJUSTMENTS.

WARNING!

ALL OF THE CHAIN LINKS MUST LIE

PROPERLY IN THE GROOVE OF THE GUIDE BAR.

WARNING!

NEVER START WORK UNLESS THE

CHAIN AND BAR ARE LUBRICATED.