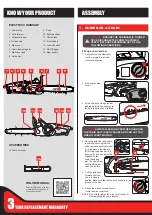

Switching on

1. Pull the hand guard/chain

brake towards you. The

brake may be stiff and may

require to be moved with

some force. If the brake is

engaged the chain will not

operate.

2. Hold the front handle with

your left hand and the rear

handle with your right hand.

3. Use the thumb of your right hand

to push the lock-off switch in and

squeeze the on/off trigger to start

the motor.

Switching off

1. Release the ON/OFF trigger. The

integrated brake will bring the

running chainsaw to a standstill

within a very short space of time.

ECS-1835

6. SWITCHING ON/OFF

RUN

BRAKE OFF

BRAKE ON

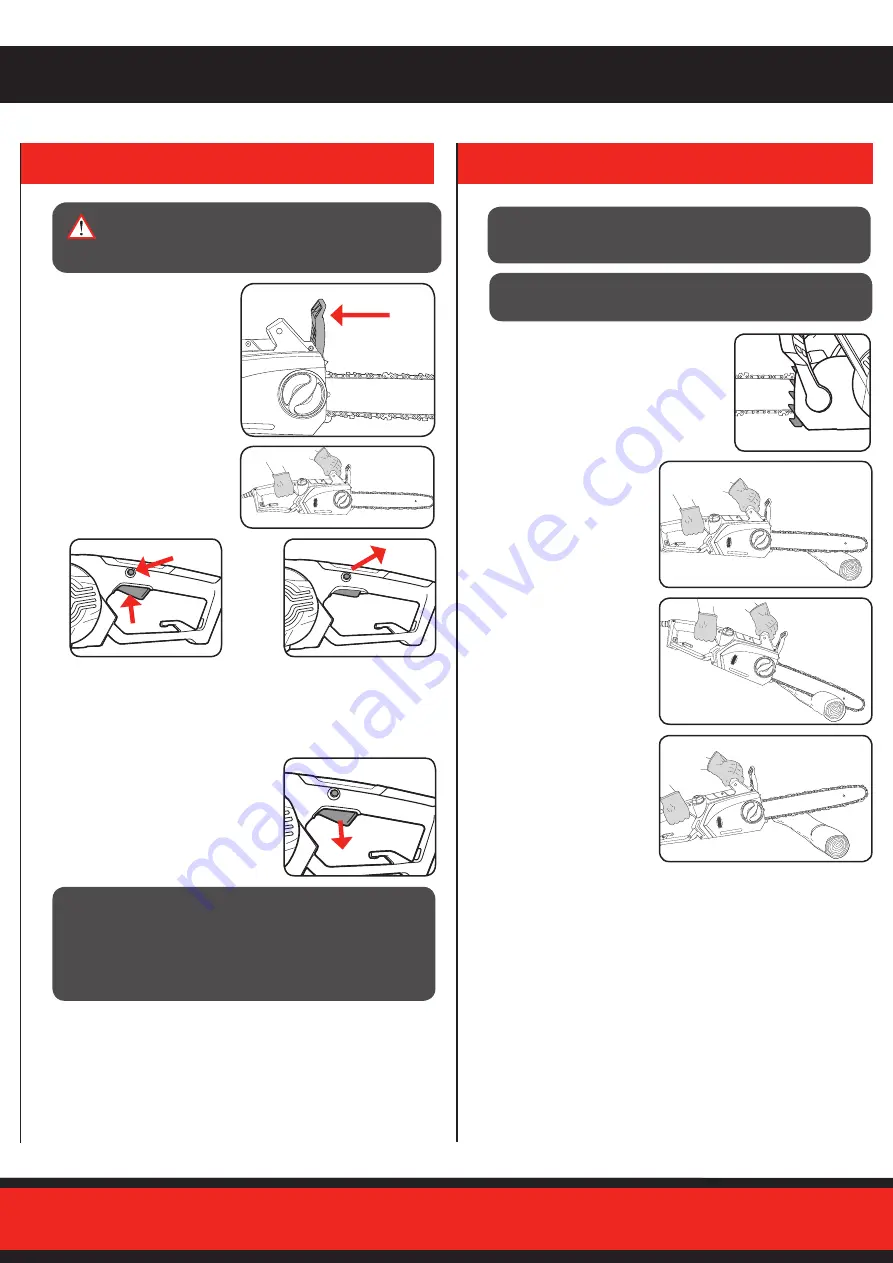

7. CUTTING

1. Press the bucking spikes against the

timber ensuring the chain is not making

contact with the material being cut.

2. Start cutting by holding

the chainsaw by the front

handle and raising the

rear handle.

3. If you cannot cut the

timber in a single stroke,

apply light pressure to the

front handle and continue

sawing, draw the chainsaw

back a little then apply the

bucking spikes a little lower

and finish the cut by raising

the rear handle.

4. Withdraw the chainsaw

from the cut while the

chain is still running.

CAUTION:

FIRST TIME USERS SHOULD, AS A MINIMUM

PRACTISE, CUT LOGS ON A SAW-HORSE OR CRADLE

CAUTION:

POSITION THE CORD SO THAT IT WILL NOT

BE CAUGHT IN BRANCHES DURING CUTTING

CAUTION!

TO REDUCE THE RISK OF ELECTRIC

SHOCK, WE RECOMMEND THE USE OF A RESIDUAL

CURRENT DEVICE (RATED AT 30mA OR LESS).

CAUTION:

ALWAYS CARRY THE SAW BY THE FRONT

HANDLE. IF THE SAW IS PLUGGED IN AND YOU CARRY

IT BY THE REAR HANDLE, THERE IS A RISK THAT YOU

COULD ACCIDENTALLY PRESS THE LOCK-OFF SWITCH

AND THE ON/OFF TRIGGER AT THE SAME TIME,

INADVERTENTLY STARTING THE CHAINSAW.

4. The chain will now be

running, ready to make a cut.

Release the lock-off switch.

Hints and tips

• Do not force the saw into the cut. Apply only light pressure whilst

running the engine at full throttle.

• If the chain gets caught in the cut, do not try to remove it by

twisting the guide or pulling forcibly. Use a lever or wedge to

open up the cut so that the chain is freed.

• While cutting, always:

– Run the chainsaw motor at full revs. This makes the job safer,

as there is less chance of pull-in or kick-back.

– Position your body to the left of the chainsaw so if it kicks back

uncontrollably, it goes over your right shoulder, never stand in

the cutting line of the saw.

– Keep a firm grip with your left hand on the front handle,

with your thumb securely below the handle.